Row unit maintenance, Seed tube maintenance, Sliding seed tube replacement – Great Plains 2510HDP Operator Manual User Manual

Page 114: Grommet maintenance

110

1510HDP/2010HDP/2510HDP

Great Plains Manufacturing, Inc.

118-245M

2013-10-21

Row Unit Maintenance

Seed Tube Maintenance

Clean inner sliding seed tube

1 if it will not slide.

Replace inner sliding seed tube if you see any visible

cracks.

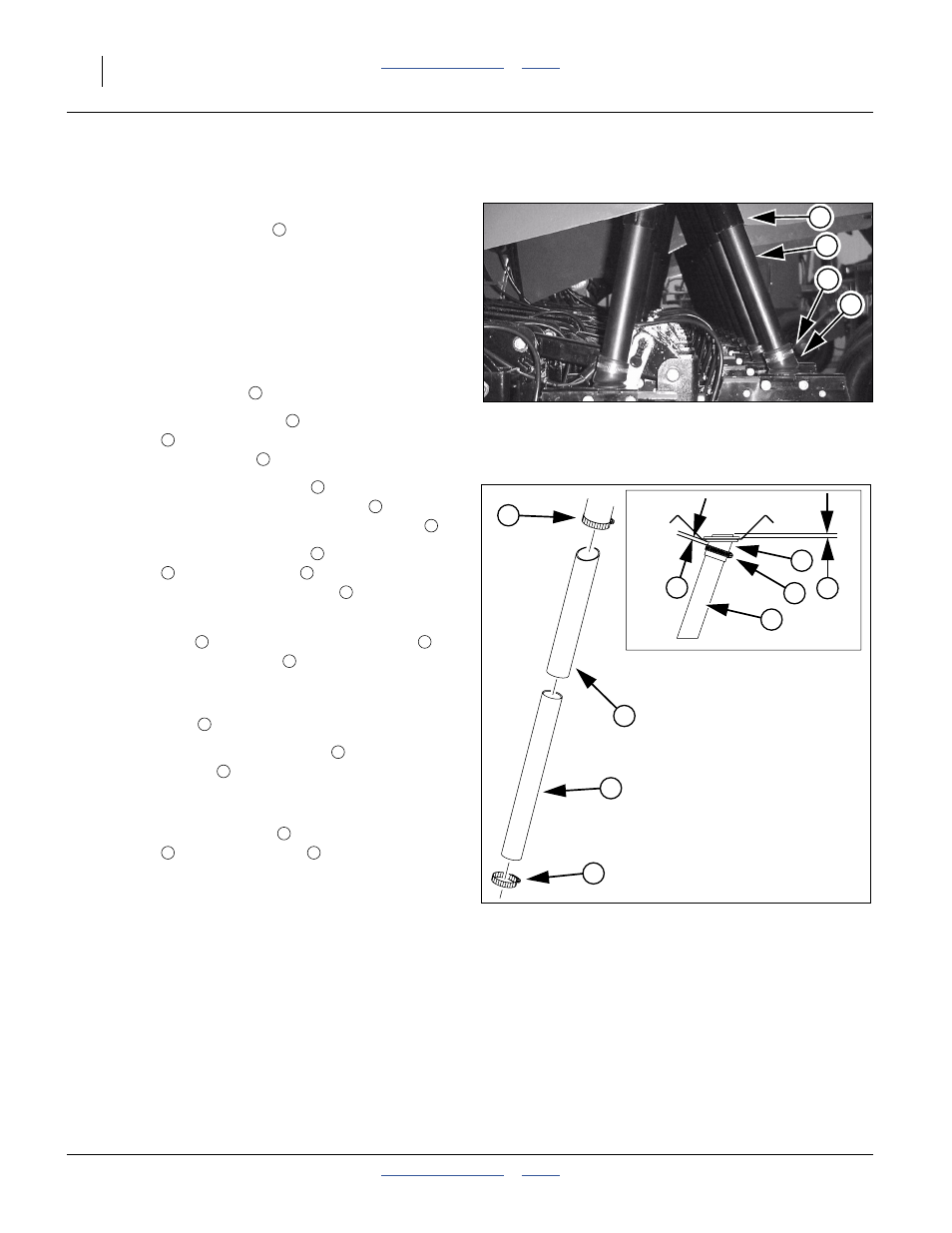

Sliding Seed Tube Replacement

Refer to Figure 114 and Figure 115

To replace inner sliding seed tube, follow these steps:

1.

Make sure seed box is empty.

2.

Loosen bottom clamp

.

3.

Pull inner sliding seed tube

out of seed meter

grommet

and pull inner tube down and out of

outer sliding seed tube

.

4.

Inspect outer sliding seed tube

for wear and

replace if necessary. Loosen top clamp

and pull

outer sliding seed tube from seed box grommet

.

5.

Fit new outer sliding seed tube

into seed box

grommet

. Set the distance

from seed box

grommet lip to the top of the clamp

to:

3

⁄

16

in (4.7mm).

6.

Set the reveal

of the outer sliding seed tube

above the rubber grommet

to:

10HD Series minimum:

1

⁄

4

in (6.4mm)

10HD Series maximum:

3

⁄

8

in (9.5mm)

Tighten clamp

.

7.

Place new inner sliding seed tube

inside outer

sliding seed tube

. If the replacement tube is

chamfered on only one end, make sure the chamfer

on the inside of the tube is up as shown.

8.

Fit inner sliding seed tube

into seed meter

grommet

and tighten clamp

.

Grommet Maintenance

Periodically check seed meter and seed box grommets

for weathering or cracking and replace as necessary.

Check sliding seed tubes at this time to make sure they

slide freely.

Figure 114

Seed Tubes

18290

1

2

4

3

1

2

1

3

4

Figure 115

Seed Tube Components

22834

5

2

1

4

5

6

4

8

7

4

5

6

4

6

7

5

8

4

6

5

1

4

1

3

2