Skip stop™ annual maintenance, Skip stop™ installation – Great Plains 3PYP Operator Manual User Manual

Page 97

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

93

2014-09-09

401-312M

Skip Stop™ Annual Maintenance

Skip Stop™

a

should be inspected on an annual basis.

Inspect cushion for wear, pockets, or other abnormalities

that may develop. Excessive wear or pocket formation

may cause seeds to become trapped and disrupt

singulation performance. As a general rule, if there is a

pocket that is large enough to hold one or more seeds

after the belt has passed by, Skip Stop™ Cushion should

be replaced.

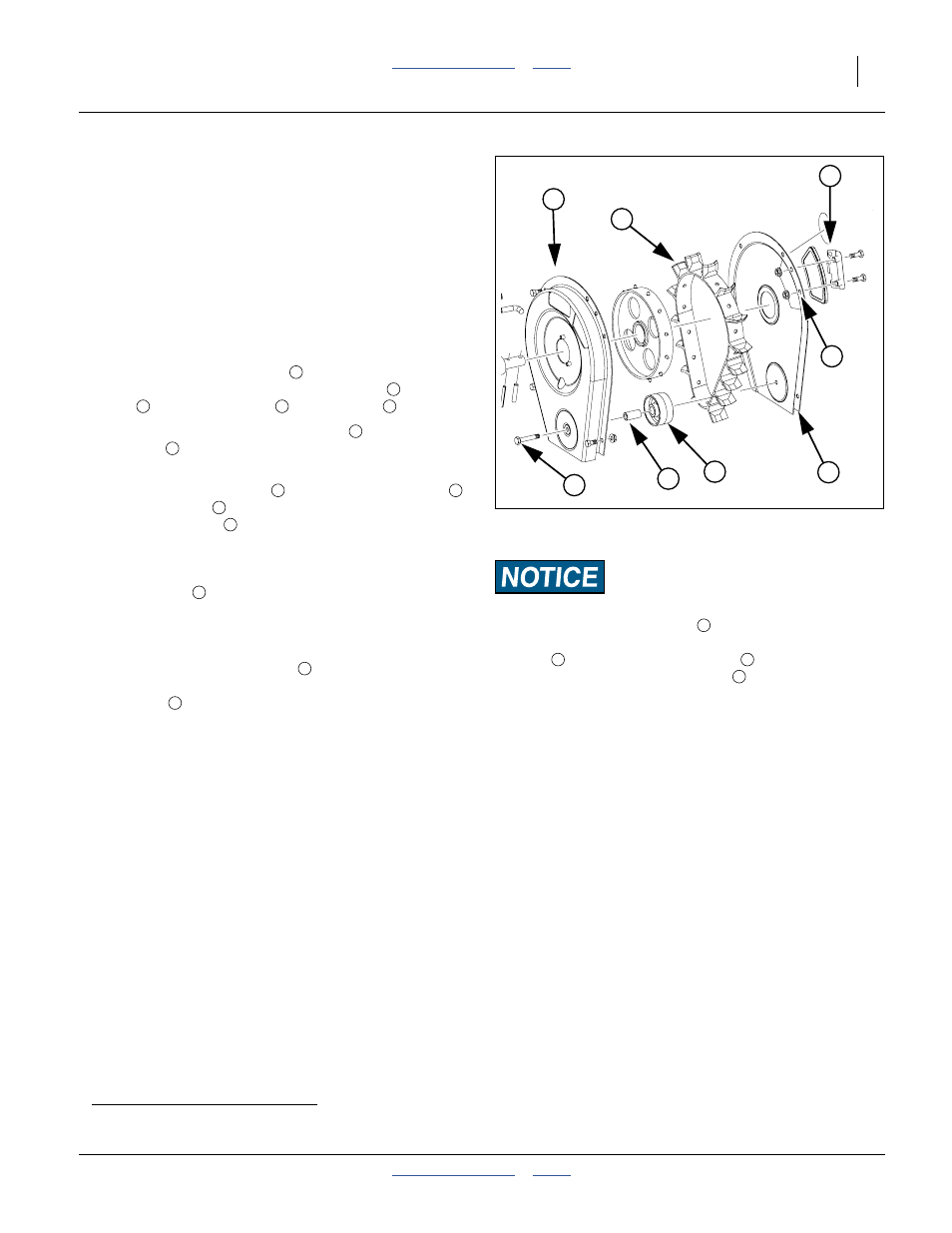

Skip Stop™ Installation

Refer to Figure 116

1.

Remove back metal cover

by removing five bolts.

Four bolts attach cover to metal housing

and one

bolt

holds idler wheel

and bushing

.

2.

Align new Skip Stop™ metal cover

over

housing

.

Note: Skip Stop™ metal cover has a hole cut out for

Skip Stop™ Cushion

. Make sure idler wheel

and bushing

remain properly aligned and insert

1

⁄

4

×

2 inch bolt

. Secure bolt loosely.

3.

Insert remaining three

1

⁄

4

×

1

⁄

2

inch bolts to fasten

metal cover to housing. Tighten all bolts securely.

4.

Tighten bolt

that secures idler wheel and turn belt

via the bearing shaft by hand to verify that belt is

centered between housing. If necessary, loosen bolt

and slide cover to adjust and re-center belt.

5.

Place Skip Stop™ Cushion

over the opening.

Insert two

1

⁄

4

×

3

⁄

4

inch bolts to secure Skip Stop™

Cushion

to housing.

a. Skip Stop™ is a trademark of Precision Planting, Inc.

Meter Performance Risk:

Make sure Skip Stop™ Cushion

is secured tightly to back

metal cover and cannot turn or rotate. Make sure Skip Stop™

Cushion

does not interfere with belt

rotation in any

manner. A loose Skip Stop™ Cushion

may result in seed

leakage, poor meter performance, and planting errors.

Figure 116

Skip Stop™

24032

7

7

5

7

3

2

6

1

5

4

7

8

6

1

2

4

3

6

1

7

4

3

2

2

7

7