Airbox troubleshooting – Great Plains 3PYP Operator Manual User Manual

Page 88

84

3PYP

Great Plains Manufacturing, Inc.

401-312M

2014-09-09

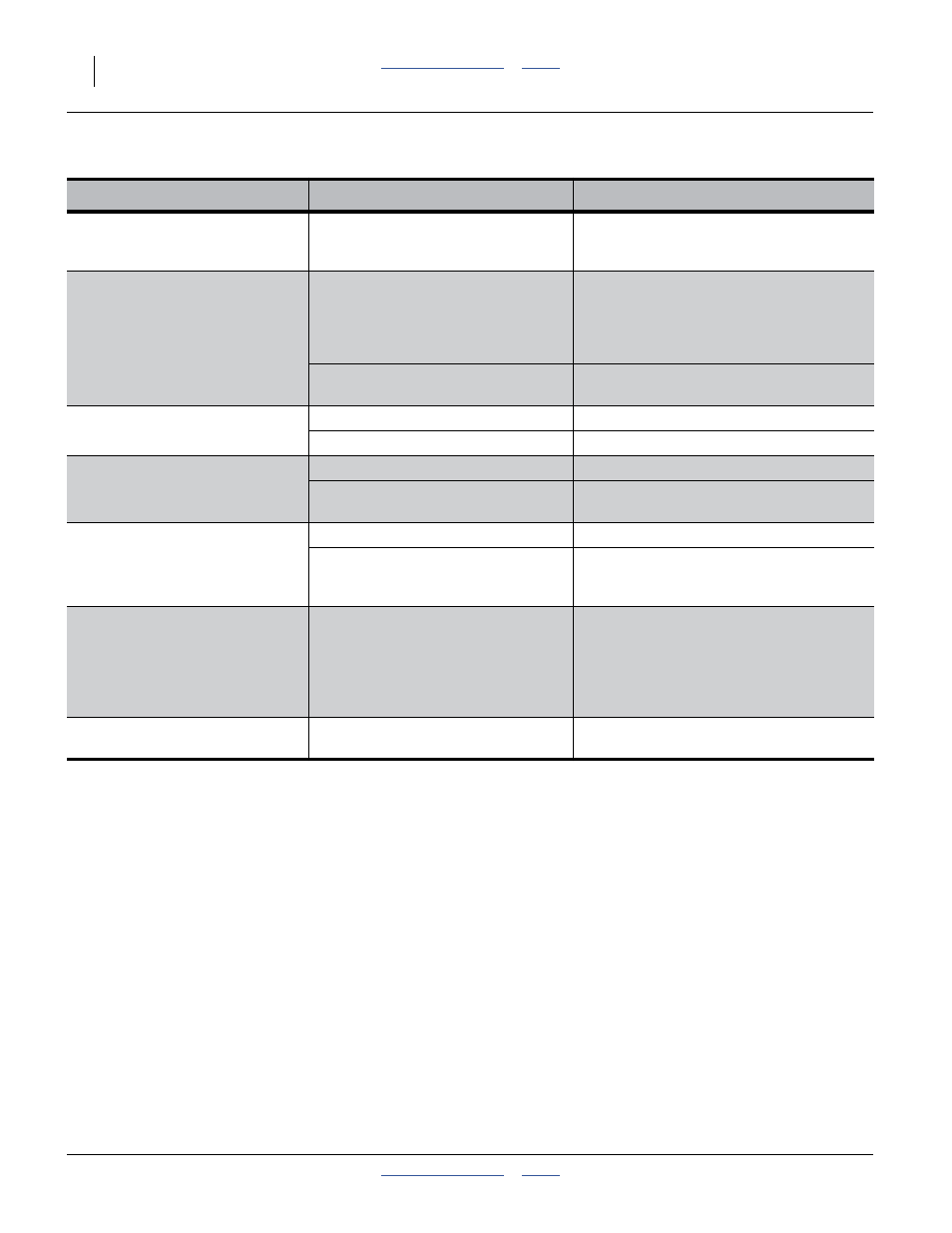

Airbox Troubleshooting

Problem

Cause

Fix

Single row doesn’t fill or keep up

with other rows.

Y-tube is bent/angled off feed pipe.

Loosen and rotate pipe so the bend is

straight down and Y-tube is not pointing to

front or rear of air pipe.

Both rows on one meter outlet low

or not keeping up with other rows.

Note: This is more likely to occur

on end outlets.

Blockage in air slot in top of airbox.

Clear by using a long slim tool and taking

hose off hose outlet or clean-out door.

Note: May be necessary to take top off

airbox to clear debris from slot.

Bad hose routing between delivery

hose and airbox on wing.

Correct hose routing.

Multiple rows fail for lack of seed. Fan speed too high/too low.

Check/adjust fan speed.

Out of seed.

Add seed.

Single or multiple hoses plugging

just ahead of airbox.

Fan speed too high/too low.

Check/adjust fan speed.

Possible air leak.

Check for air leak downstream between

box and top of meter.

All rows fail.

Lack of seed.

Add seed.

Fan speed too high.

Adjust fan speed.

Extremely high populations may require

slightly reduced field speed.

1, 2, 3, or more outlets fail.

Note: Outlets can be side-by-side

or random. Plugging may

also move from one outlet

to another.

Foreign matter in seed chamber in

bottom of airbox.

Clean out seed chamber.

Little or no seed to many rows,

with heavily treated seed.

Seed treatment sticky.

Add talc to seed to dry out seed treatment.