Gauge wheel tension, Contact drive adjustments, Gauge wheel tension contact drive adjustments – Great Plains 3PYP Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

Adjustments

51

2014-09-09

401-312M

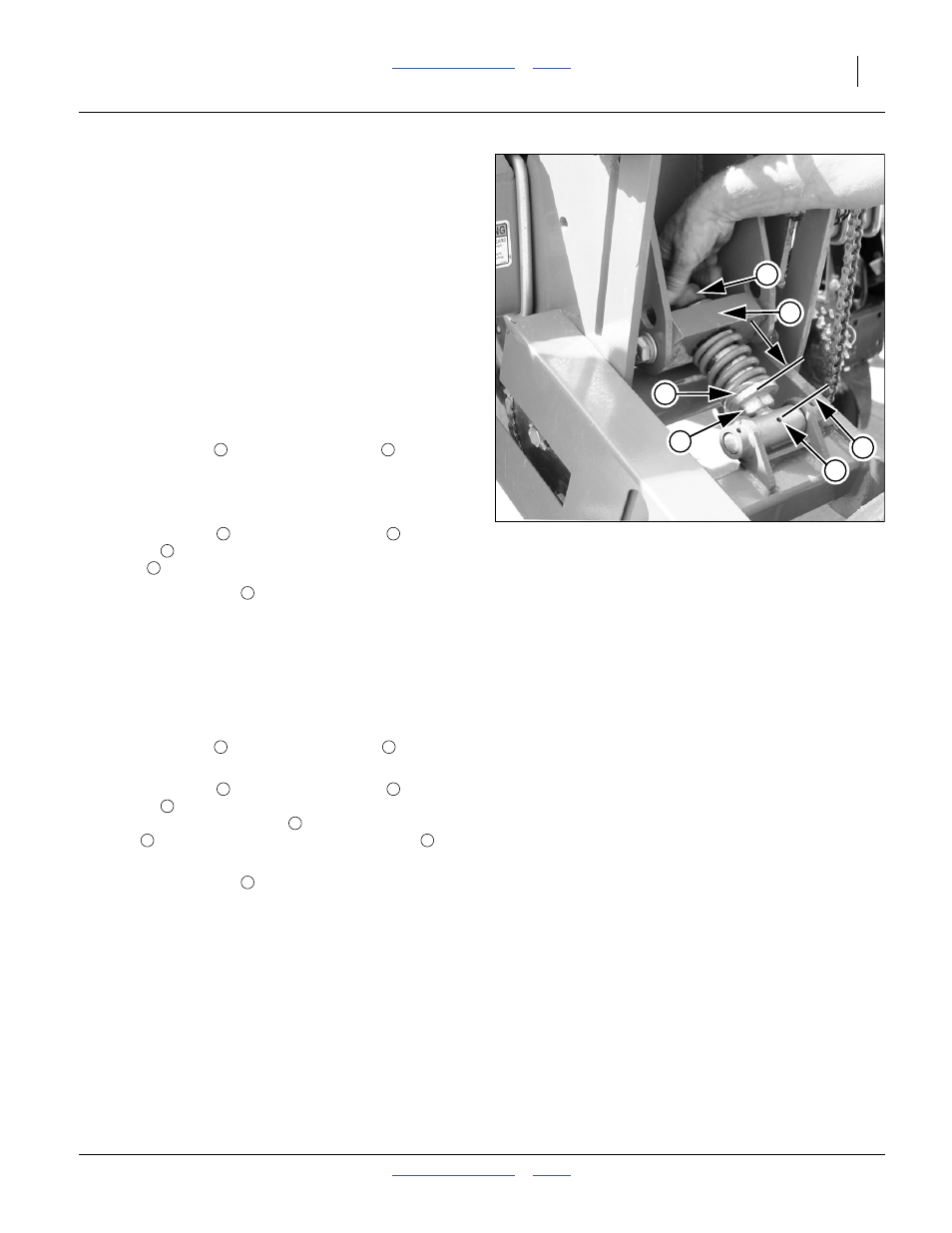

Gauge Wheel Tension

Refer to Figure 52

Before performing this step, the 3PYP center section and

wings must be level and aligned, and the tool bar height

must be set to 26 inches. If these steps have not been

performed, “Frame Height and Leveling” on page 18

and “Wing Leveling” on page 157.

As the gauge wheel tire wears, this adjustment may need

periodic attention.

The planter must be on firm, level ground for this step

(which may be performed when the planter leveling is

done). The planter must be unfolded.

1.

Raise the planter so that the gauge wheels are just

off the ground.

2.

Loosen the nut

above the yoke block

.

3.

Raise or lower the planter so that the base of the tool

bar is 26 inches from the ground.

4.

Using an open-end or adjustable wrench at the

integral hex nut

the link

until the spring is just touching the yoke

block

, with neither gap nor compression.

5.

Tighten the top nut

.

Contact Drive Adjustments

When planting, if the monitor indicates under-seeding,

check for slippage of the gauge wheels. If they are

slipping:

1.

Raise the planter so that the gauge wheels are just

off the ground.

2.

Loosen the nut

above the yoke block

.

3.

Using an open-end or adjustable wrench at the

integral hex nut

the link

to adjust the gauge wheel tension. Using

the base of the link flange

, and the pivot grease

zerk

as a reference, increase this distance

increase down-force on the wheel.

4.

Tighten the top nut

.

Figure 52

Adjusting Gauge Wheel Tension

25258

1

2

4

3

5

6

1

2

4

1

1

2

4

4

6

1