Field set-up checklist – Great Plains 3PYP Operator Manual User Manual

Page 45

Great Plains Manufacturing, Inc.

Operating Instructions

41

2014-09-09

401-312M

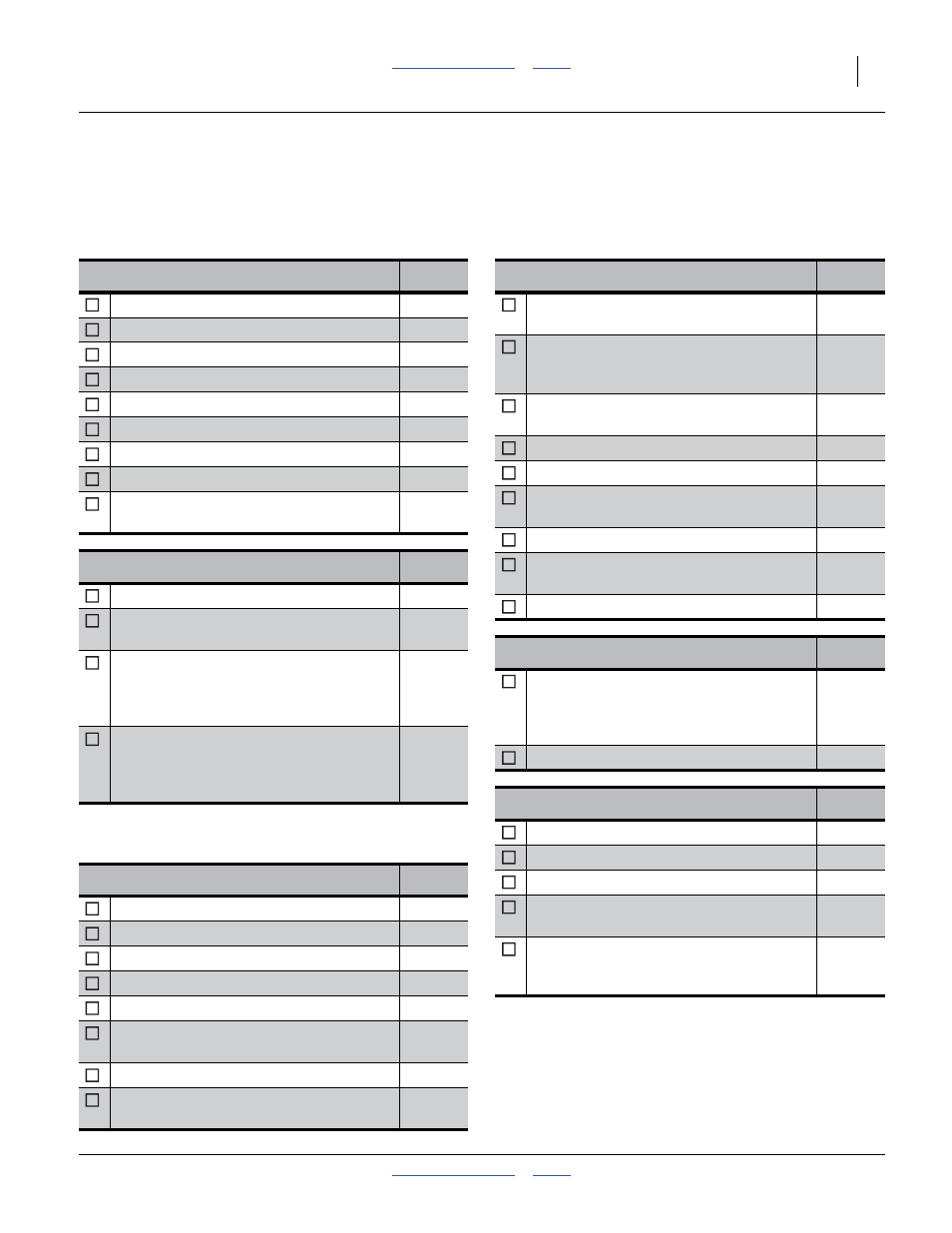

Field Set-Up Checklist

Use the following tables to develop a final checklist for

your tractor/planter configuration. Additional or fewer

steps may be necessary depending on tractor features,

planter options and planting accessories.

Mechanical Checklist

Page

Tongue height preset on 3-point

18

3-point top link adjusted (if used)

14

Planter unfolded

Front-to-rear level

Side-to-side level at gauge wheels

Marker tilt complete

Marker initial length set

Marker disc angle set

Markers folded (unless already at start of

first planting row)

Electrical Checklist

Page

Verify electrical hookups solid

Power up monitor and observe any

diagnostic messages

a

a. Refer to monitor manual.

With hydraulic circuits in neutral, check

switches and indicator lights on CLUTCH

and FRAME switch panel. Return all

switches to OFF.

25

If equipped with hydraulic planter drive,

verify that radar speed sensor is pointed

at ground, at an angle approximately 35

°

below horizontal.

b

b. Refer to sensor documentation.

Air System Checklist

Page

Manifold to seed box or hopper seal

-

Seed loaded

Seed lubricated

Tube gates turned on to correct rows

No air leaks (except from seed box)

-

Hose routings - no sags, no pinches

(check wing-folded & field positions)

-

Clean-out doors closed at meters

Hoses fully connected to meters and

locked

Row Units Checklist

Page

Preset depth handles to 7 holes showing

above “T”

Preset down force springs to first notch

(lightest) setting for most conditions, 2nd

notch otherwise)

Set all unit-mounted coulters to

1

⁄

4

in

shallower than opener blades.

Check coulter alignment to row

Check closing wheel alignment

Set closing wheels to first notch (light

setting)

Engage meter clutch for all desired rows

Check action and contact of side depth

wheels

Gauge wheel scraper gap (if installed)

Row Cleaners Checklist

Page

Outer wing cleaners clear of center

section hoses (wings folded). Observe

cleaners during wing unfold to ensure

none catch on hoses.

23

Cleaner depth setting

Fertilizer (Option) Checklist

Page

Check tractor-mounted components

a

a. Check supplier manual for tanks and pump. Check

fertilizer section of monitor manual.

Check for correct orifice plates

b

b. Check Seed Rate manual, and manual for fertilizer

pump system.

Check unused rows correctly closed off

Fill system half full with water, and check

for leaks - run pump if possible

-

Check all row unit lines are connected,

free of kinks, and discharge tube/nozzles

are clear

-