Marker maintenance, Marker shear bolt replacement, Marker chain length adjustment – Great Plains 3PYP Operator Manual User Manual

Page 92

88

3PYP

Great Plains Manufacturing, Inc.

401-312M

2014-09-09

Marker Maintenance

Marker Shear Bolt Replacement

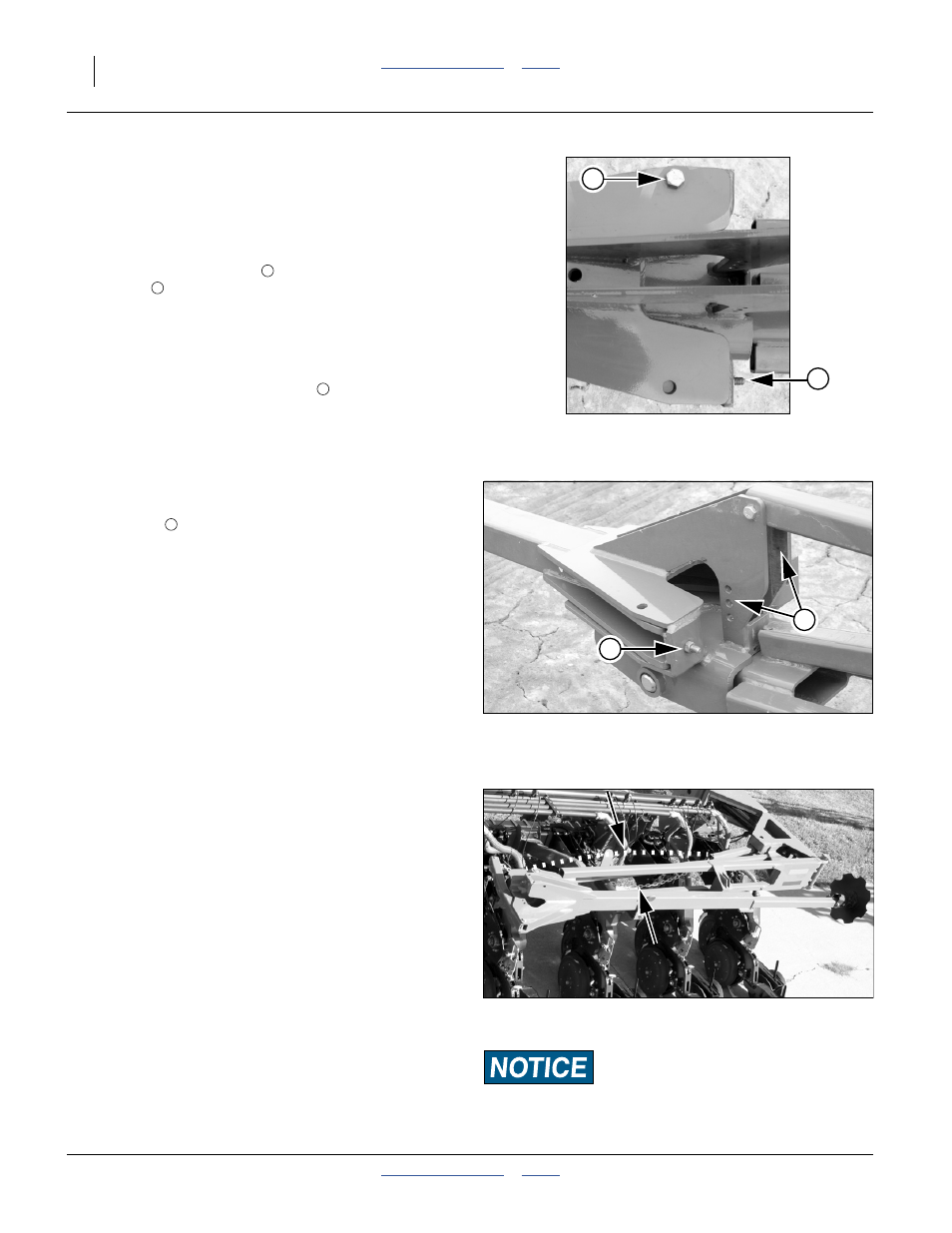

Refer to Figure 105

If a marker gets caught or hits an obstruction, it is

designed to fail a shear bolt

at the fold, pivot on a

second bolt

, and swing back.

The shear bolt is a hex head cap screw,

7

⁄

16

-14

×

2 inch

Grade 5, Great Plains part number 802-589C, plus a

7

⁄

16

-14 lock nut, Great Plains part number 803-200C.

Install a replacement shear bolt on the vertical faces on

the side opposite from the pivot bolt

higher grade bolt, or marker hang-ups may result in

machine damage. Do not use a lower grade bolt, or you

may experience nuisance shears.

Refer to Figure 106

If your planting frequently encounters shear hazards, you

can store 6 spare shear bolts/nuts per marker side, in

storage holes

at the fold point.

Marker Chain Length Adjustment

Great Plains suggests checking marker chain slack

every few years. If any maintenance or repairs cause the

chain to be disconnected, correct slack needs to be set

on reinstallation.

Perform any checks and adjustments with the marker

folded and tilted down into its cradle.

Refer to Figure 107

At the midpoint in the exposed chain, pull it toward the

front of the planter.

Measure the distance between that mid-point and the

nearest point on either of the two parallel tubes of the

marker intermediate arm. The target value is:

18 inches (46 cm).

If the slack is outside this range, remove the bolt and nut

at the lower end of the chain and adjust the length.

Figure 105

Marker Shear Bolt

25263

2

1

1

2

Figure 106

Marker Shear Bolt Storage

25264

3

3

A chain length too short or too long can result in marker

damage.

Figure 107

Marker Chain Slack

25266