Transmig vaf4 – Tweco VAF4 Transmig User Manual

Page 72

TRANSMIG VAF4

SERVICE

4-8

Manual 0-5231

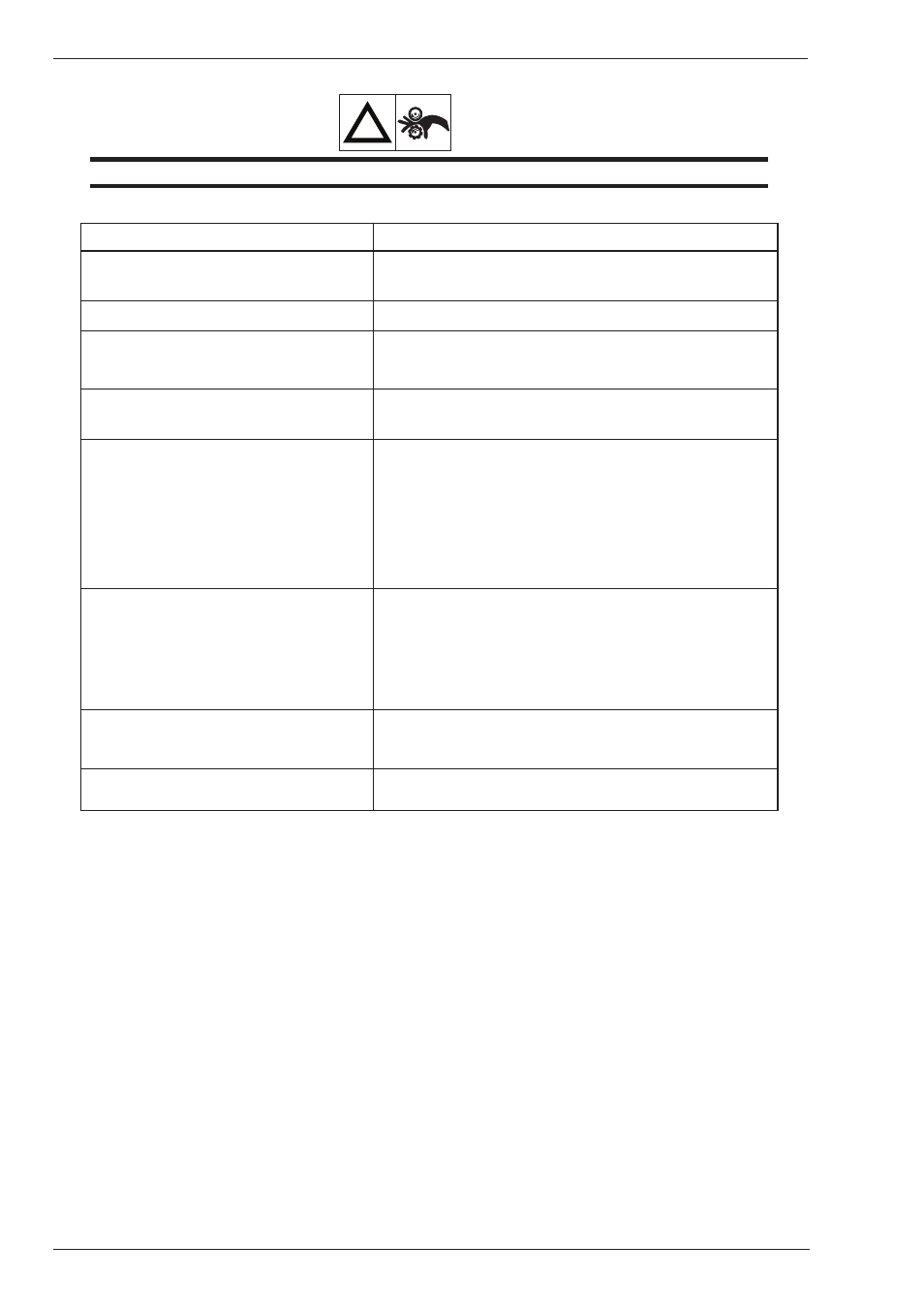

Problem 2 - Inconsistent Wire Feed

!

WArNING

Disengage the feed roll when testing for gas flow by ear.

Wire feeding problems can be reduced by checking the following points.

FAULT

CAUSE

1

Feed roller driven by motor in the cabinet

slipped.

Wire spool brake is too tight.

2

Wire spool unwound and tangled.

Wire spool brake is too loose.

3

Worn or incorrect feed roller size

A

Use a feed roller matched to the size you are welding.

B

Replace feed roller if worn.

4

Wire rubbed against the misaligned guides and

reduced wire feed ability.

Misalignment of inlet/outlet guides

5

Liner blocked with swarf

A

Increased amounts of swarf are produced by the wire passing

through the feed roller when excessive pressure is applied to the

pressure roller adjuster.

B

Swarf can also be produced by the wire passing through an

incorrect feed roller groove shape or size.

C

Swarf is fed into the conduit liner where it accumulates thus

reducing wire feed ability.

6

Incorrect or worn contact tip

A

The contact tip transfers the weld current to the electrode wire. If

the hole in the contact tip is too large then arcing may occur inside

the contact tip resulting in the wire jamming in the contact tip

B

When using soft wire such as aluminium it may become jammed in

the contact tip due to expansion of the wire when heated. A contact

tip designed for soft wires should be used.

7

Poor work lead contact to work piece

If the work lead has a poor electrical contact to the work piece then

the connection point will heat up and result in a reduction of power

at the arc.

8

Bent liner

This will cause friction between the wire and the liner thus reducing

wire feed ability

Table 4-3 Wire Feeding Problems