Transmig vaf4 – Tweco VAF4 Transmig User Manual

Page 58

TRANSMIG VAF4

INSTALLATION, OPERATION AND SETUP

3-40

Manual 0-5231

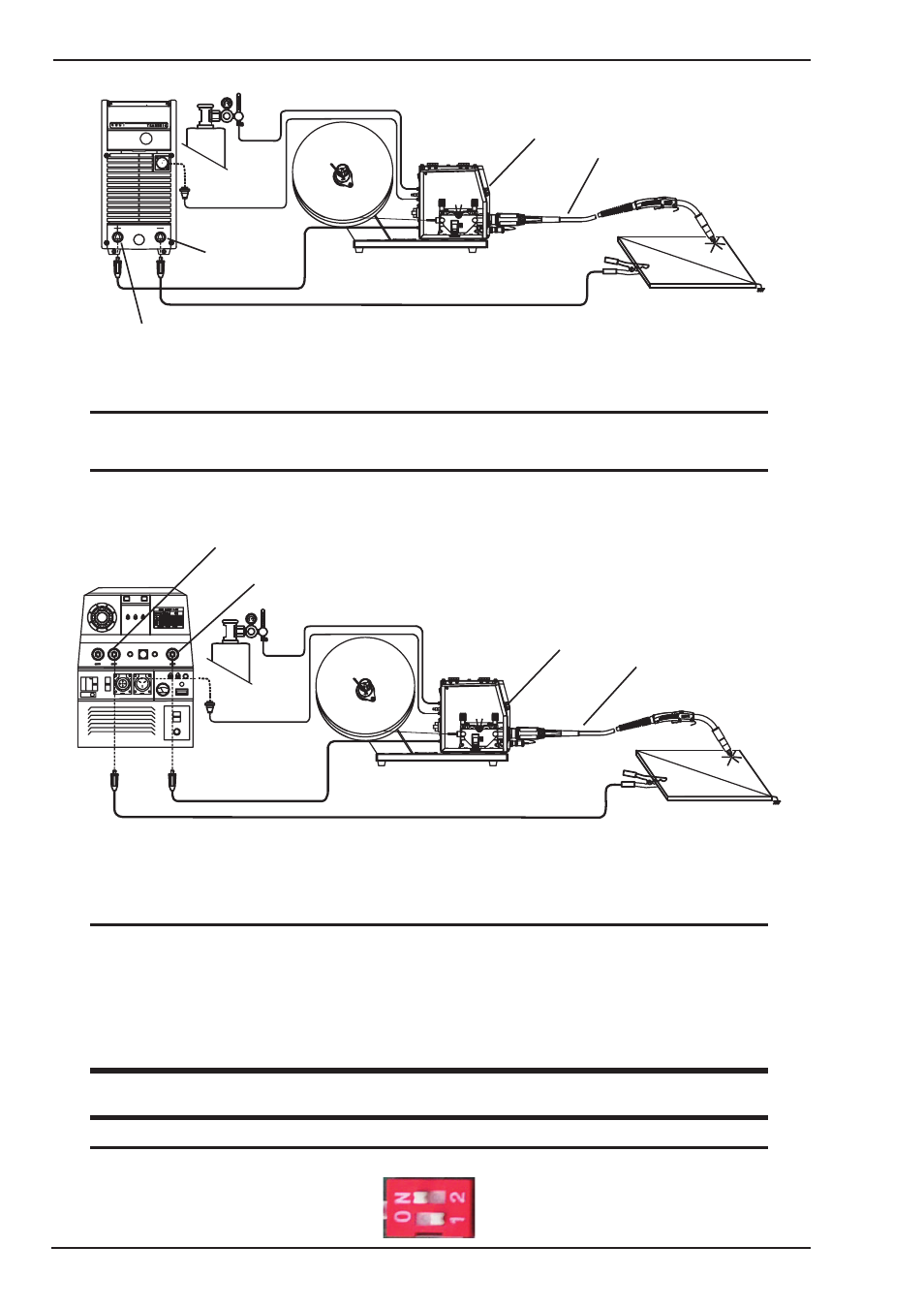

Connection of VAF4 to Transmig 400i for Welding with Gas Shielded MIG Wire

Art # A-11345

Mig Torch

VAF4 Wirefeeder

Gas

14-pin Control Cable

Electrode Lead*

Work Lead*

Positive Welding Terminal (+)

Negative Welding Terminal (-)

*These leads may need to be reversed when using flux cored welding wire.

Contact the welding wire manufacturer for more details.

Figure 3-37(b) Setup for Wirefeeder with MIG (GMAW) Welding

NOTE

Interconnection Assembly 19 pin to 14 pin, 8m (W4016000) required.

NOTE

Refer to Subsection 3.09 for wirefeeder DIP switch setting required for Transmig 400i power source.

Connection of VAF4 to Engine Drive for Welding with Gas Shielded MIG Wire

Art # A-11346

Gas

Electrode Lead*

Work Lead*

14-pin Control Cable

VAF4 Wirefeeder

Positive Welding Terminal (+)

Negative Welding Terminal (-)

*These leads may need to be reversed when using flux cored welding wire.

Contact the welding wire manufacturer for more details.

Mig Torch

Figure 3-37(c) Setup for Wirefeeder with MIG (GMAW) Welding

NOTE

Interconnection Assembly 19 pin to 14 pin, 8m (W4016000) required for connection to an MPM8/ 255

or MPM8/ 270 engine-driven welding power source.

An additional adaptor cable W4016001 is required in conjunction with a 19 pin to 14 pin interconnec-

tion cable assy (Refer to Table 2-3 for further detail) for connection to MPM12/ 400 or MPM20/ 500

engine-driven welding power source.

WARNING

There are dangerous voltage and power levels inside this product. Turn OFF wirefeeder and disconnect

from the power source before removing cover from wirefeeder.

NOTE

Refer to Subsection 3.24 and set internal DIP switch SIL_1 # 2 to ON.