Hmc-410 – Tweco HMC-410 User Manual

Page 47

HMC-410

July 27, 2005

4-5

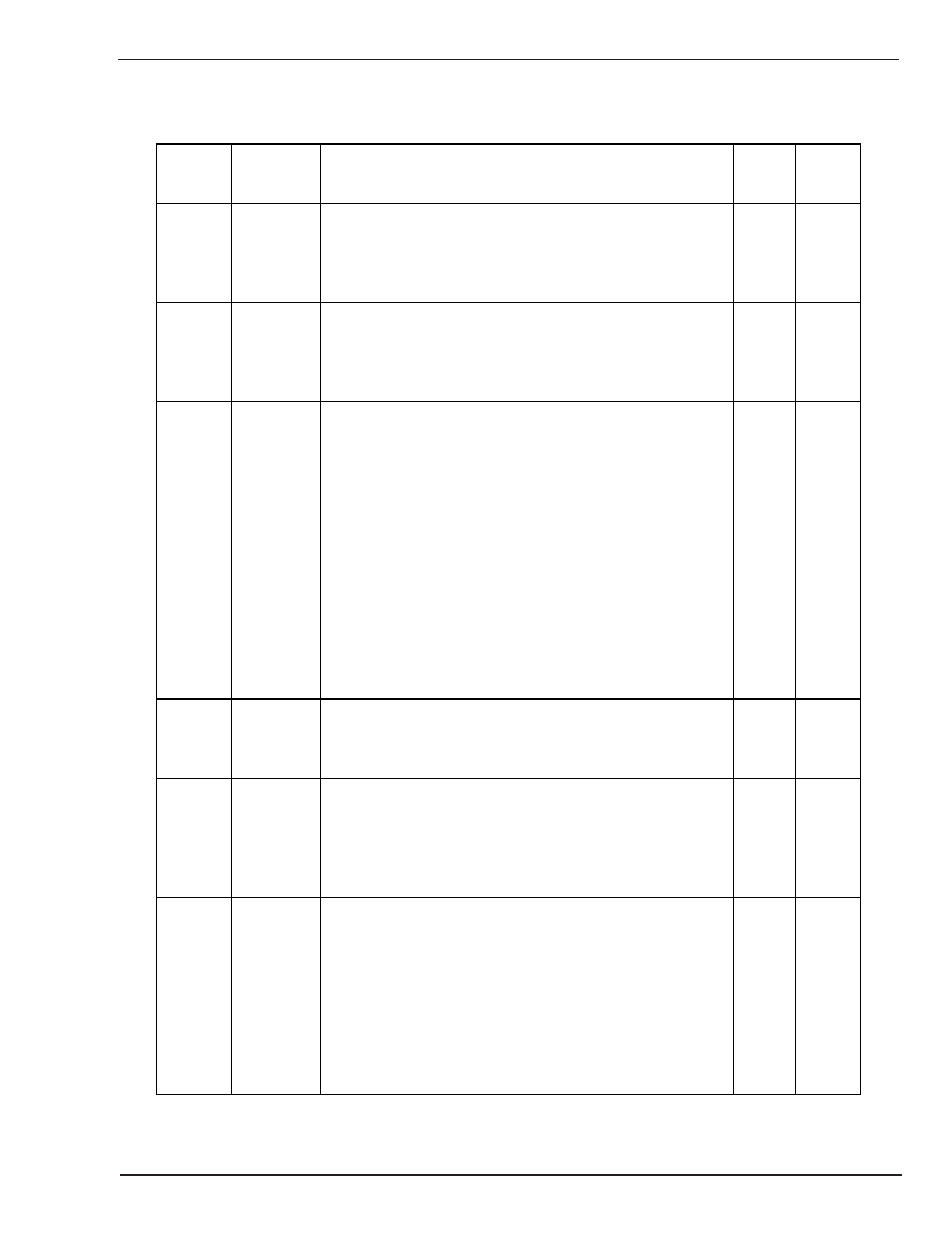

Software

Dash

Display

Feature

Description

Settings Number

BBE

Burnback

This setting may be ON or OFF. If ON, the system will operate

ON,

17+

Enable

as the ‘standard’ system did for burnback. If burnback if OFF,

OFF

the system will not allow the burnback settings to be

programmed. Also, burnback will not execute in the weld

sequence.

RCE

Recycle

This setting may be ON or OFF. If ON, the system will operate

ON,

17+

Enable

as the ‘standard’ system did for recycle. If recycle is OFF, the

OFF

system will not allow the recycle settings to be programmed

(including the sub segment features!). Also, recycle will not

execute in the weld sequence.

RSE

Random

This feature allows the HMC-410 to execute with multiple,

ON,

8+

Schedule

remotely selectable schedules (up to 8). The remote pendant

OFF

Enable

start, stop, and auxiliary segment advance pins are

reconfigured to binary coded decimal (BCD) to select the

schedule number, as shown in Table 2. The schedule may be

changed while in standby, or while welding (without stopping

the arc). If the user has selected less schedules (in the Number

of Schedules above), then the random schedule operation is

limited to those schedules enabled. For example, if the

Number of Schedules is 4, then random schedule operation is

limited to schedules 1 to 4, and any schedule selected above

4 will be use schedule 4 instead. The schedule is selected by

opening or shorting these pins to Auxiliary Pin H (+30

VDC). See following Random Schedule Select Table for

details on schedule selection.

FPE

Front Panel

This feature allows the user to disable the front panel Cycle

ON,

17+

Enable

Start button. The Cycle Start button is disabled when this is

OFF

set to OFF. The button will still allow a cycle test to be run from

the Cycle Start button when in the test mode.

BID

Built In Delay This setting configures the 410’s built in delay time between

0 to .50

17+

burnback and postflow. This time allows the ExcelArc,

ArcMaster, Ultraflex, and PowerMaster power sources to

perform their wire sharpening and/or built in burnback features

before the 410 signals an end of cycle. This number defaults

to .50 seconds, and may be set to 0 to .50 seconds.

ESE

Electrode

This setting allows the 410 to sense a wire stuck to the work

ON,

19+

Stick

condition by checking the voltage at the output terminals of the

OFF

Enable

power source. Should the welding output of the power source

short out (have less than 2.0 volts across the output terminals)

when not welding, then an electrode short has occurred. When

ESE is set to ON, then this will trigger an error. When ESE is

set to OFF, the check is ignored and no error is generated.

This mode is meant to be used with the PowerMaster or

ArcMaster power sources with an 870210 board installed. This

board is typically part of the 870236 robotic interface kit.