Hmc-410 – Tweco HMC-410 User Manual

Page 34

HMC-410

2-16

July 27, 2005

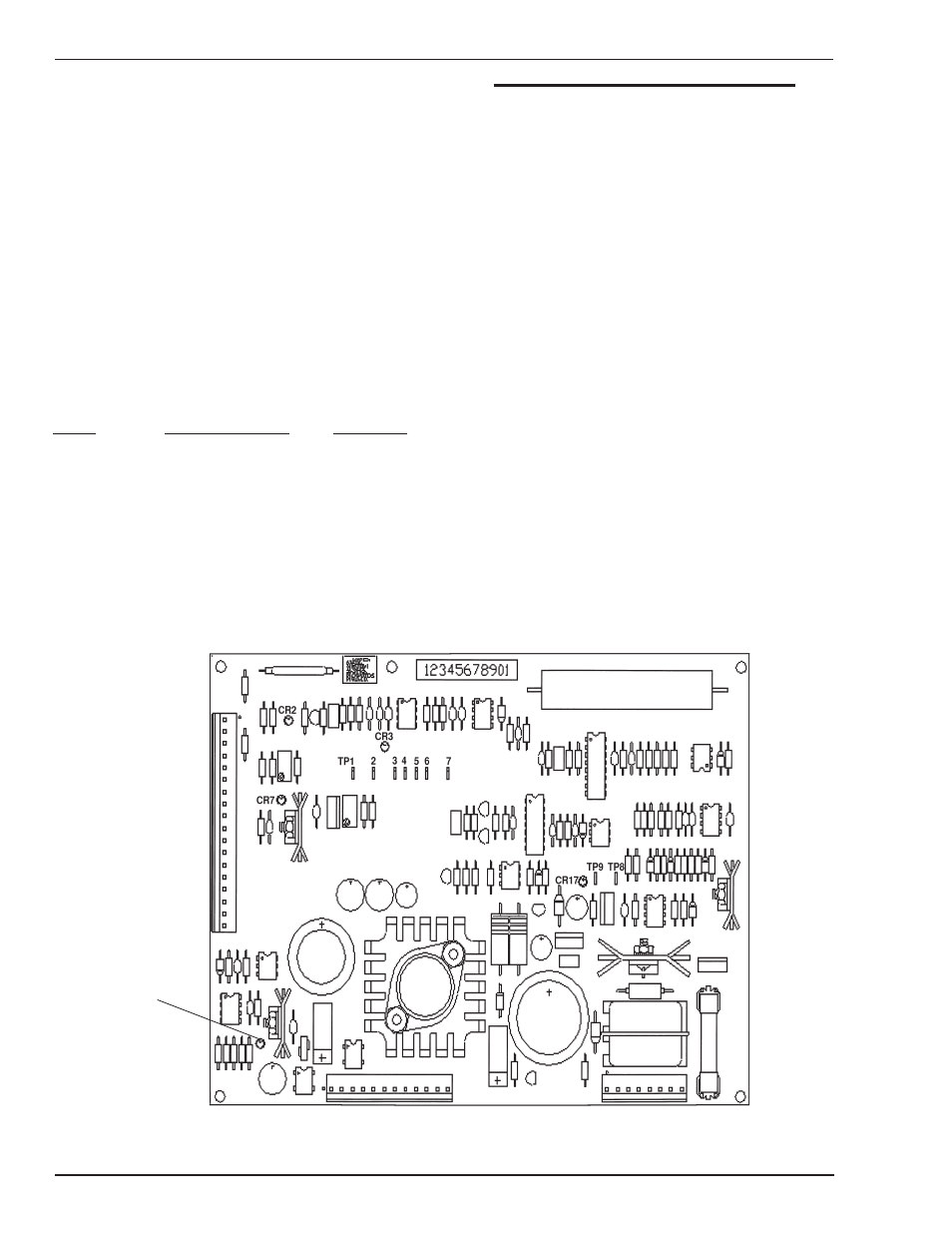

Power Supply/Motor Control PCB Assembly

(Refer to Figure 2-7)

The Power Supply/Motor Control PCB Assembly (PS/MC

Board) has two functions. It provides the various low

voltage control voltages used by the solid state circuitry

throughout the HMC-410. It also translates control signals

from the controller board into power for the motor.

The power supply section of the board utilizes the off

board transformer to divide the line voltage down to the

voltage levels used by the circuitry in the system. The

rough functionality of this circuitry can be performed by

visually inspecting the LEDs on the board. If the LED is

lit, then the voltage is at least approximately what it should

be. In order to verify the exact voltages, a meter can be

used on the following test points:

HI LO

Expected Reading

Status LED

TP1 TP2

–15 VDC (± .05 VDC)

CR3

TP3 TP2

+5 VDC (± .5 VDC)

CR7

TP4 TP2

+15 VDC 1 (± .05 VDC) CR2

TP5 TP7

+15 VDC 2 (± .5 VDC)

CR9

TP6 TP7

+15 VDC UNREG

CR8

(+25 to +35 VDC)

TP7 TP9

+12 VDC (±.5 VDC)

CR17

NOTE

These measurements and repairs should be

performed only by a qualified electrical

technician.

The motor control circuitry drives the DC motor which

feeds the filler metal used in the MIG process. There are

various protection circuits which will disable the motor

control circuitry should it detect an excessive load on the

motor or control circuitry. Some of these protections

require that the panel’s power be cycled to reset them.

Also, the fuse F5 could blow should the motor current

exceed its limits. Should these shutdowns continuously

set, check that the filler metal can freely feed. If it is not

impeded, verify that the cabling is not damaged. The PS/

MC board interconnects to the transformer, the controller

board, and the interface/suppressor board.

CR9

Art # A-04363

Figure 2-7: Power Supply/Motor Control PCB Assembly