Hmc-410 – Tweco HMC-410 User Manual

Page 46

HMC-410

4-4

July 27, 2005

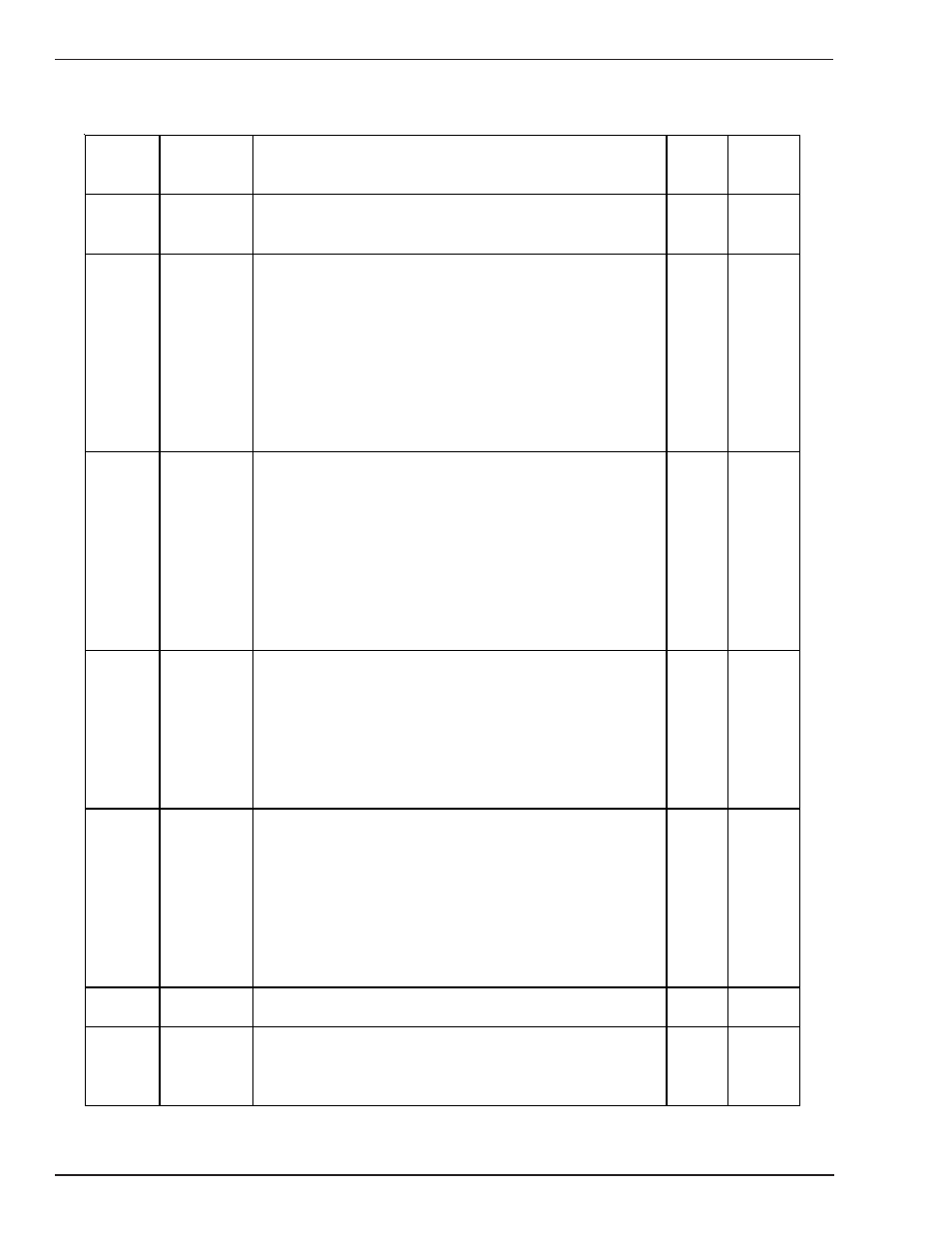

Software

Dash

Display

Feature

Description

Settings Number

AHR

Arc Hour

When this switch is in the ON position, the Arc Hour Timer will

ON, OFF 3+

Timer Reset

be reset to 0. After resetting the timer, this parameter will

automatically reset itself to OFF.

SSE

Weld

When this switch is in the ON position, the multiple Weld

ON,

3+

Sub Segment Sub segment feature of the control panel is enabled. This

OFF,

Enable

feature is used to change the weld parameters because of a

HAR

discontinuity in the work or for start and end weld tweaking of

the arc. This feature is described in the sections on

Semiautomatic Operation and Auxiliary Interface Operation.

When this switch is OFF, the control panel will ignore

instructions to use the next sequential Weld Sub Segment

parameters. When this switch is HAR, the mode is set by the

optional front panel switch.

HDE

Trigger Hold

ON: Trigger Hold ON. Pull and release gun switch to start an

ON,

3+

Enable

arc. Weld will continue without holding gun switch. Pull and

OFF,

release gun switch to stop an arc.

HAR

OFF: Trigger Hold OFF. Pull gun switch to start and maintain

welding arc. Release gun switch to end the welding arc.

HAR: Trigger Hold mode is set by the optional trigger hold

switch on the front panel. When HAR is selected and the

trigger hold switch is up, trigger hold is OFF. When HAR is

selected and the trigger hold switch is down, trigger hold is

ON.

DF

Display Filter This feature sets the responsiveness (jitter) of the welding

0.00 to

17+

displays. This number sets the amount of time between each

1.00

new screen update (in seconds). The arc voltage, arc current,

and actual wire feed speed displays are all affected. The data

is averaged over that time frame. A number of 1.00 seconds

is the slowest that the displays will change, giving a very stable

but deadened response. A number below .05 will give a very

lively, but sometimes unreadable response.

SP

Switch Period This number sets gun switch responsiveness. This number

0.00 to

17+

sets the amount of time that the gun trigger must stay in its

1.00

current position before it is recognized. A change faster than

this number is used when ‘flickering’ the gun trigger to advance

to the next weld sub segment. For example, if this number is

set to .30 (seconds), any changes on the gun trigger faster

than .30 seconds will advance the sub segment (if that feature

is on), and any gun trigger action slower than .30 seconds will

stop the weld.

NOS

Number of

This number allows the customer to set the number of

1 to 8

8+

Schedules

schedules in use. This number may be set from 1 to 8.

CFE

Crater fill

This setting may be ON or OFF. If ON, the system will operate

ON,

17+

Enable

as the ‘standard’ system did for crater fill. If crater fill is OFF, the

OFF

system will not allow the crater fill settings to be programmed.

Also, crater fill will not execute in the weld sequence.