Rockwell Automation 6723-PCO DATA PROCESS CONFIG OPERATIO User Manual

Page 5

Process Configuration and Operation Software for Windows

t

3

Publication 6723Ć10.1 Ć August 1996

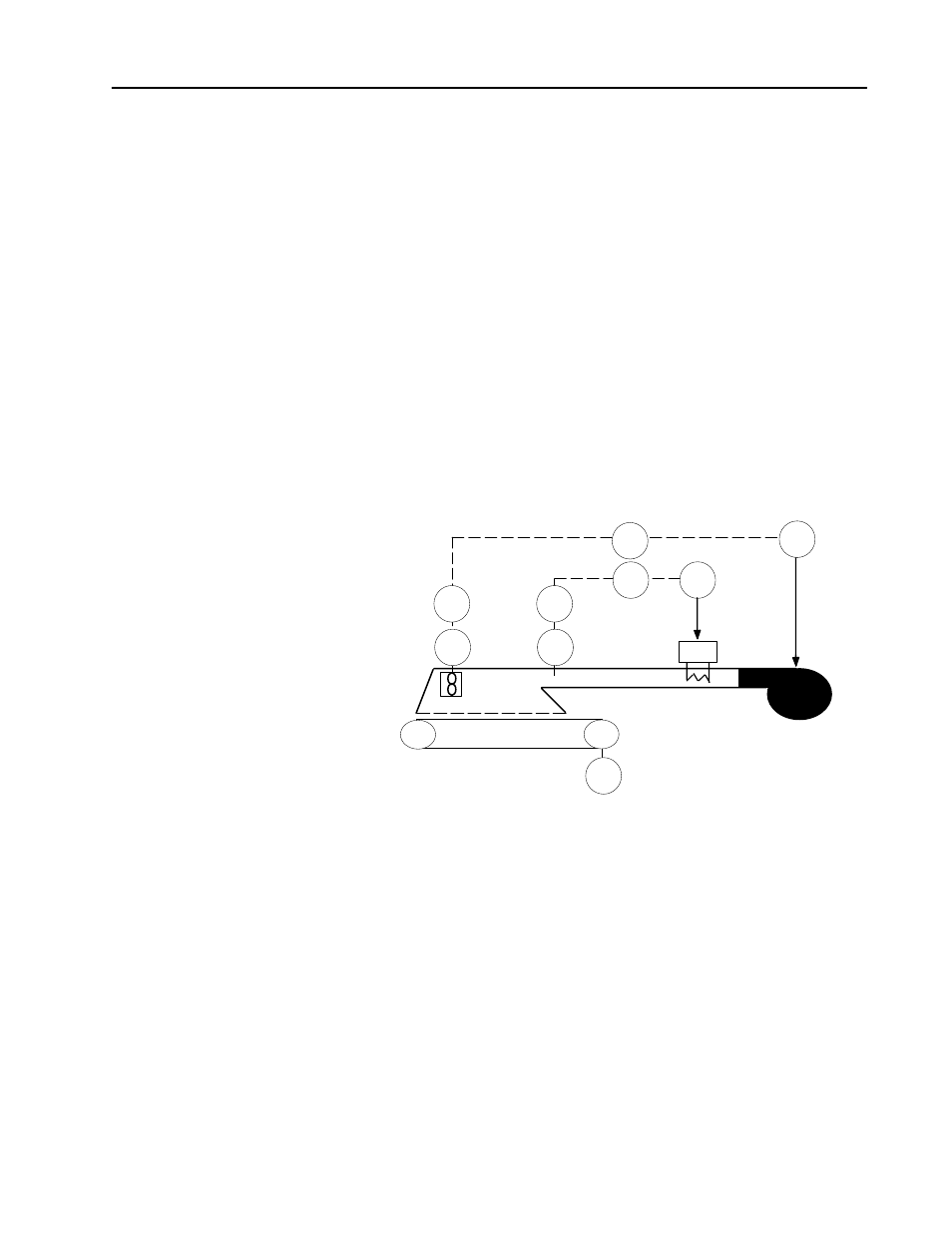

Throughout this Quick Start, we will focus on the development of a

grain-drying application. By following this example through from

start to finish, you will be able to get a feel for the development of a

typical process control application. In the interest of clarity, we will

keep this example as simple as possible.

Grain-drying applications are used to dry grain for storage before its

use. In these applications, it is very important that the control system

have the ability to control air and temperature loops independently;

proper drying temperature must be maintained despite changes in the

ambient temperature in unheated buildings or variations in drying air

flow. Furthermore, temperature or heat must be applied to the air to

ensure that moisture is removed by the time the grain reaches the end

of the dryer, or the storage bin.

Air flow must also be maintained above a minimum level so as to

ensure complete moisture removal and avoid hot spots that could

brown the grain, but not exceed a high flow that would blow grain

off the line.

HS

103

FT

100

FE

100

FIC

100

TT

101

TE

101

TIC

101

TY

101

conveyor

M

SCR

2 Regulatory Loops

Ć Flow loop (100)

Ć Temperature loop (101)

2 Analog in (4Ć20 mA)

2 Analog out (4Ć20 mA)

Conveyor control (103)

Ć Auto/Manual

Interlocks

Ć Temperature loop

FY

100

For the purposes of this application example, we can assume the

following specific control requirements:

•

Loop control must include complete Auto/Manual control (e.g.

bumpless mode transfers, anti-reset windup, alarms on PV,

setpoint ramping, etc.).

•

Process measurement and control equipment is 4-20 mA.

The temperature loop must be interlocked with air flow to prevent

browning (or, in the worst case, a fire) if the air flow is less than a

specified minimum, or if the temperature is greater than a

specified maximum.

•

Conveyor control is On/Off control, and is normally controlled

from the PLC logic.

In addition, the operator must be able to control the motors in a

Manual mode from the supervisory station.

Overview of the ForcedĆAir

GrainĆDrying Application

Example