Wiring procedure -10, Wiring procedure – Rockwell Automation 1746-NO8V SLC 500 8-Point Analog Output Module/ User Manual User Manual

Page 18

Publication 1746-UM026A-EN-P - September 2003

2-10 Installation and Wiring

Wiring Procedure

To wire your module, follow these steps:

1. Determine the length of cable you need to connect a channel to

its field device. Remember to include additional cable to route

the shield wire and foil shield to their ground points.

2. At each end of the cable, strip some casing to expose the

individual wires.

3. Trim the exposed signal wires to 50 mm (2 in) lengths. Strip

about 5 mm (3/16 in.) of insulation away to expose the end of

each wire.

4. At one end of the cable, twist the shield wire and foil shield

together, bend them away from the cable, and apply shrink

wrap.

5. At the other end of the cable, cut the drain wire and foil shield

back to the cable and apply shrink wrap.

6. Connect the wires to the terminal block and field device as

shown in Figure 2.1 on page 2-11. The recommended maximum

terminal screw torque is 0.7 to 0.9 Nm (6 to 8 in-lb) for all

terminal screws. Excessive tightening can strip the terminal

screw.

7. Repeat steps 1 through 6 for each channel on your module.

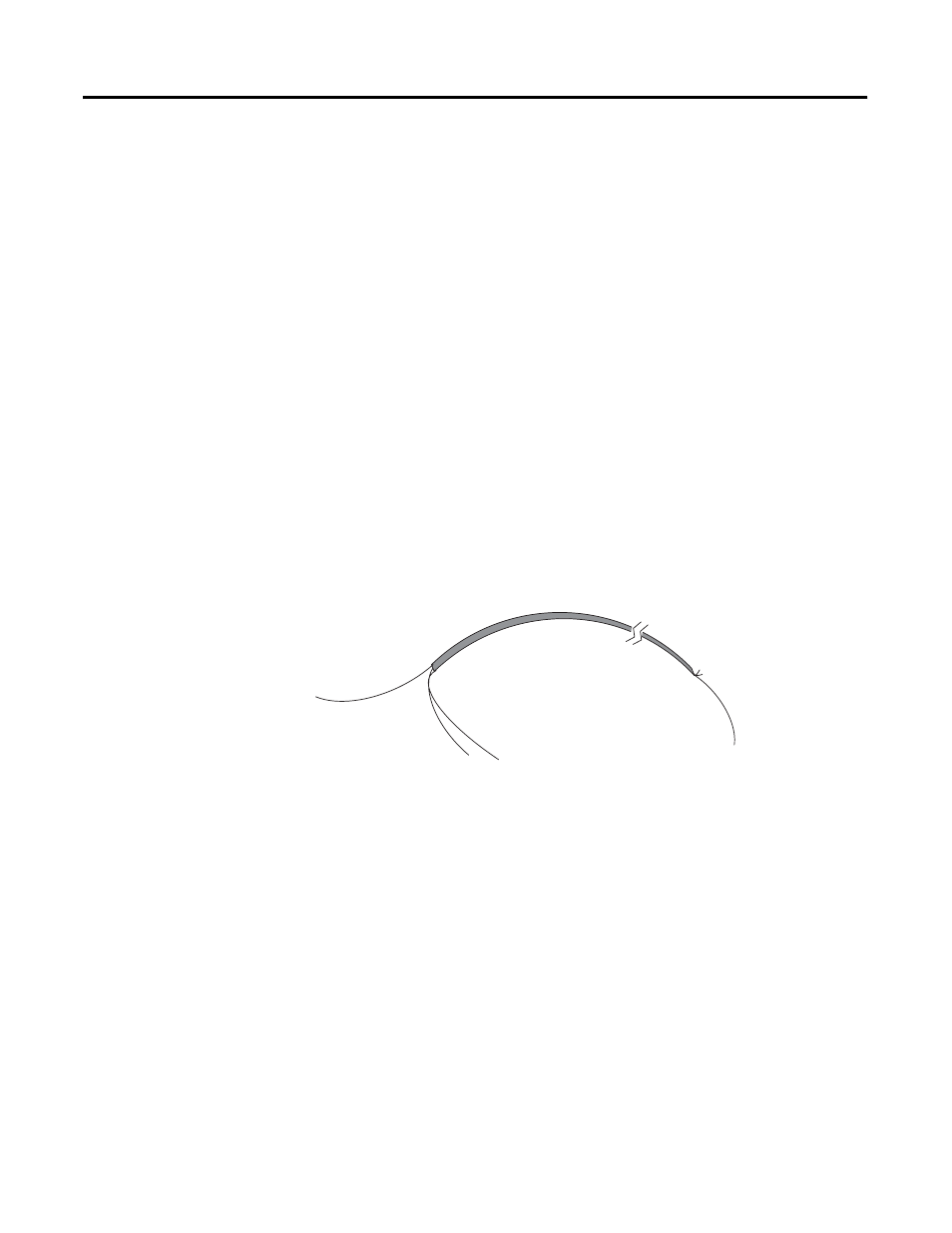

Cable

(Cut foil shield and drain wire.)

Signal Wire

Foil Shield

Drain Wire

Signal Wire

Twist the drain wire and the foil shield together and connect

to earth ground or to the chassis mounting screws.