Output pulse testing – Rockwell Automation 440C Guardmaster 440C-CR30 Configurable Safety Relay User Manual User Manual

Page 37

Rockwell Automation Publication 440C-UM001C-EN-P - November 2014

37

Pulse Testing

Chapter 5

The purpose of the test pulses is to detect short circuits from the input signal to

24V DC, 24V common, and shorts from one input signal to another input signal.

If one input signal is assigned to Test Pulse A and another signal is assigned to

Test Pulse B (or C), then a short circuit from one input to the other is detected by

the CR30, and the CR30 de-energizes the outputs of those safety functions using

the two inputs. In this example, you cannot select terminal 12 as one test pulse

source and terminal 15 as the second test pulse source, as both of these produce

the “A” pulse.

The CCW automatically prevents the user from selecting two of the same pulses

when dual channel inputs and two test sources are selected.

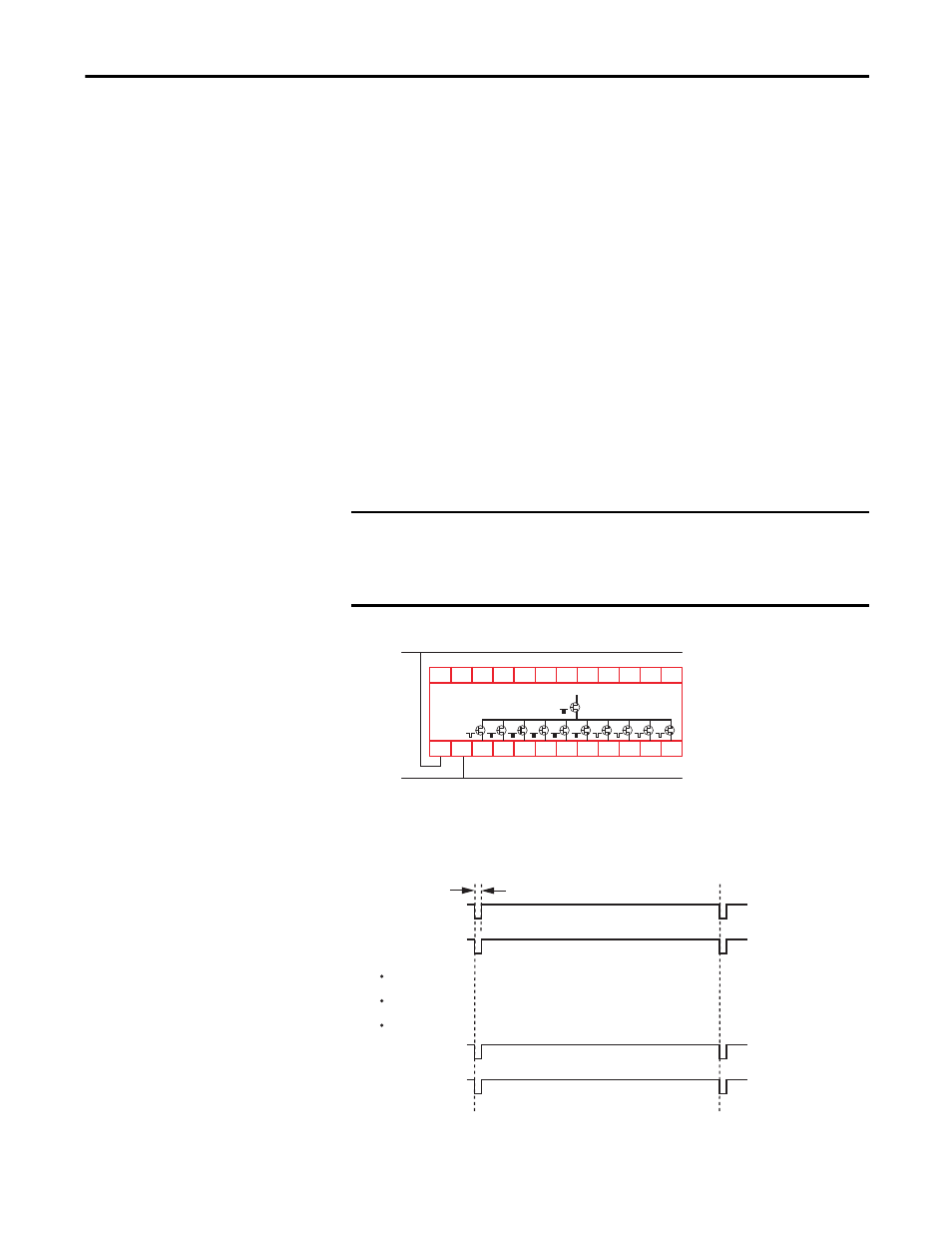

Output Pulse Testing

Internally, the CR30 provides dual channel capability to turn off its safety

outputs. Conceptually, think of this as a main output transistor feeding

individual output transistors. The CR30 repeats a test process where it tests the

main transistor twice and then sequentially tests each individual output twice.

After successful completion of the tests, the CR30 repeats the test sequence.

Figure 20 - Output Pulse Testing

When the main transistor is tested, a 50 μs test pulse appears simultaneously on

all outputs. The main transistor is tested again 125 ms later.

Figure 21 - Main Transistor Test

IMPORTANT

Safety systems requiring a Category 4 structure per ISO13849-1 and SIL 3

rating per IEC61508 must use pulse testing for the dual channel outputs. Pulse

testing for Category 3, 2, and 1 structures and SIL 2 and 1 ratings is

recommended.

+24V DC

24V Com

05

CR30

02

01

00

03 04

A1

15

20 21

16

06

18

A2

07

19

08

10 11

12 13 14

09

17

Main Transistor

Terminal 13

Terminal 12

24V

0V

24V

0V

Terminal 20

Terminal 21

24V

0V

24V

0V

0

125ms

50μs