Rockwell Automation LPM20 Liquid-Cooled AC Drive with High Performance Drive Control User Manual

Page 39

Installation/Wiring

1-27

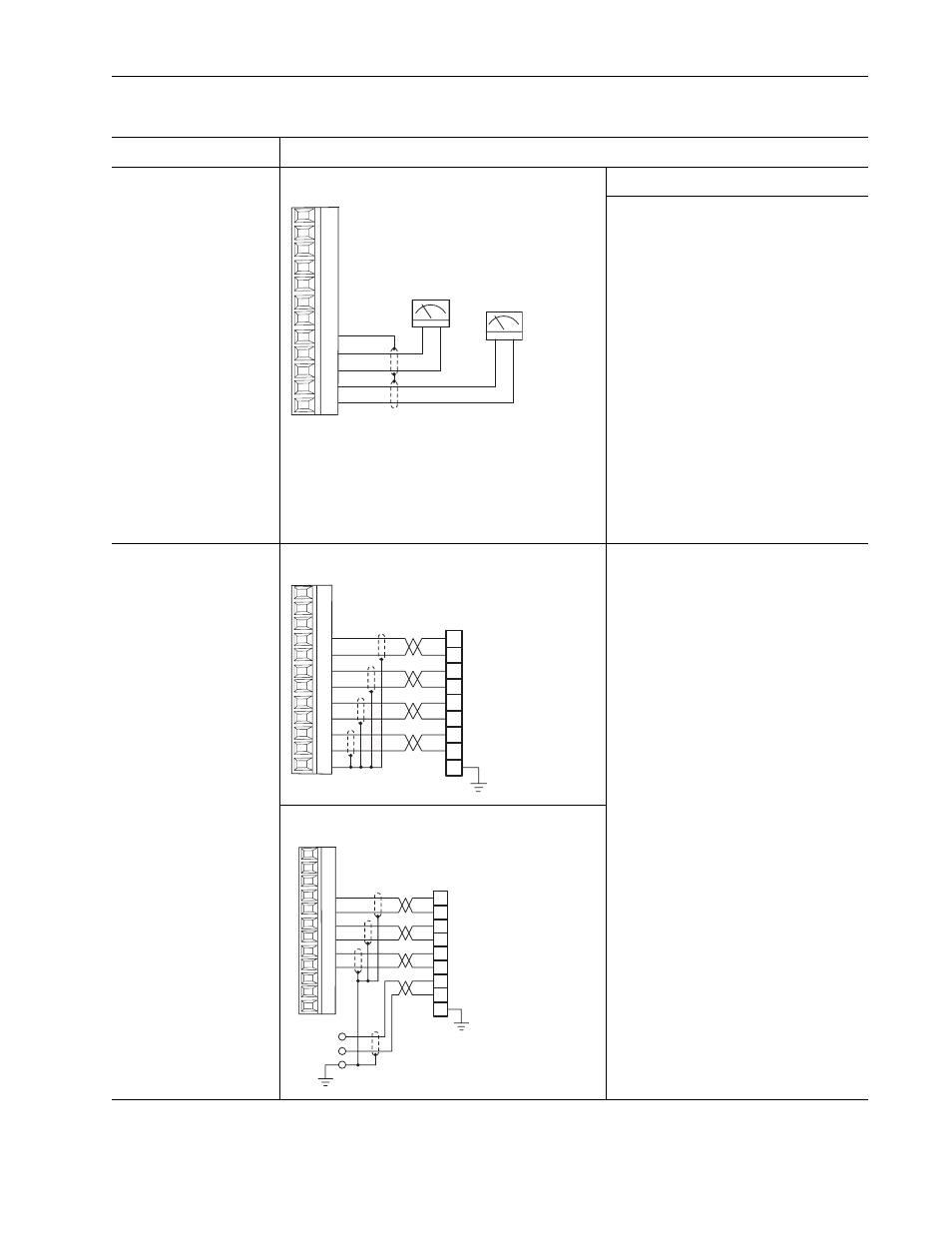

Analog Output

+/- 10V dc

Used to drive analog meters

displaying speed and current.

0-10V Analog Output

Required Parameter Changes

Using Analog Output 1 (-10V to +10V) to meter

Motor RPM and direction:

• Send the data to the Analog Output Parameter

833 [Anlg Out1 Real], the destination, linked to

Parameter 71 [Filtered SpdFdbk], the source.

• Scale the Output to the source parameter.

Example: Parameter 835 [Anlg Out1 Scale] =

175 (where Parameter 4 [Motor NP RPM] 1750

is divided by 10V output).

Using Analog Output 2 (-10V to +10V) to meter

Motor current:

• Send the data to the Analog Output Parameter

840 [Anlg Out2 Real], the destination, linked to

Parameter 308 [Output Current], the source.

• Scale the Output to the source parameter.

Example: Parameter 822 [Anlg Out2 Scale] = xx

(where Parameter 2 [Motor NP FLA] is divided

by 10V output).

Primary Encoder Interface -

Supports 5V dc/12 V dc

differential encoders with

internal power supply.

Primary Encoder - Internal Supply

Using Encoder 0 as speed feedback:

• Set Parameter 222 [Motor Fdbk Sel Pri] to a

value of 0 (Encoder 0 = default), so the drive will

use this encoder as the primary motor speed

feedback device.

• Set the value of Parameter 232 [Encoder 0

PPR] to match the installed encoder’s resolution

(Pulses per Revolution).

Primary Encoder - External Supply

Figure 1.10 TB1 Terminals — Analog Wiring Examples (Continued)

Input/Output

Connection Example

-

+

-

+

1

2

3

4

5

6

7

8

9

12

10

11

A-

-

+

Z-

Z

B-

B

A

Encoder

The Z channel is not

required in typical

applications

13

14

15

16

17

18

19

20

21

22

23

24

A-

-

+

Z-

Z

B-

B

A

Encoder

The Z channel is not

required in typical

applications

Power +V

Common -V

Shield

13

14

15

16

17

18

19

20

21

22

23

24