Safety precautions, L1 l2 l3 – Rockwell Automation 20B PowerFlex 700 Drives - Frame 10 Components Replacement User Manual

Page 11

Rockwell Automation Publication 20B-IN026B-EN-P - July 2013

11

Preface

Safety Precautions

Follow all the precautions and general installation requirements provided in the

PowerFlex 700 Frame 7-10 Installation Instructions (publication

and the PowerFlex 700 User Manual (publication

) along with those

included here.

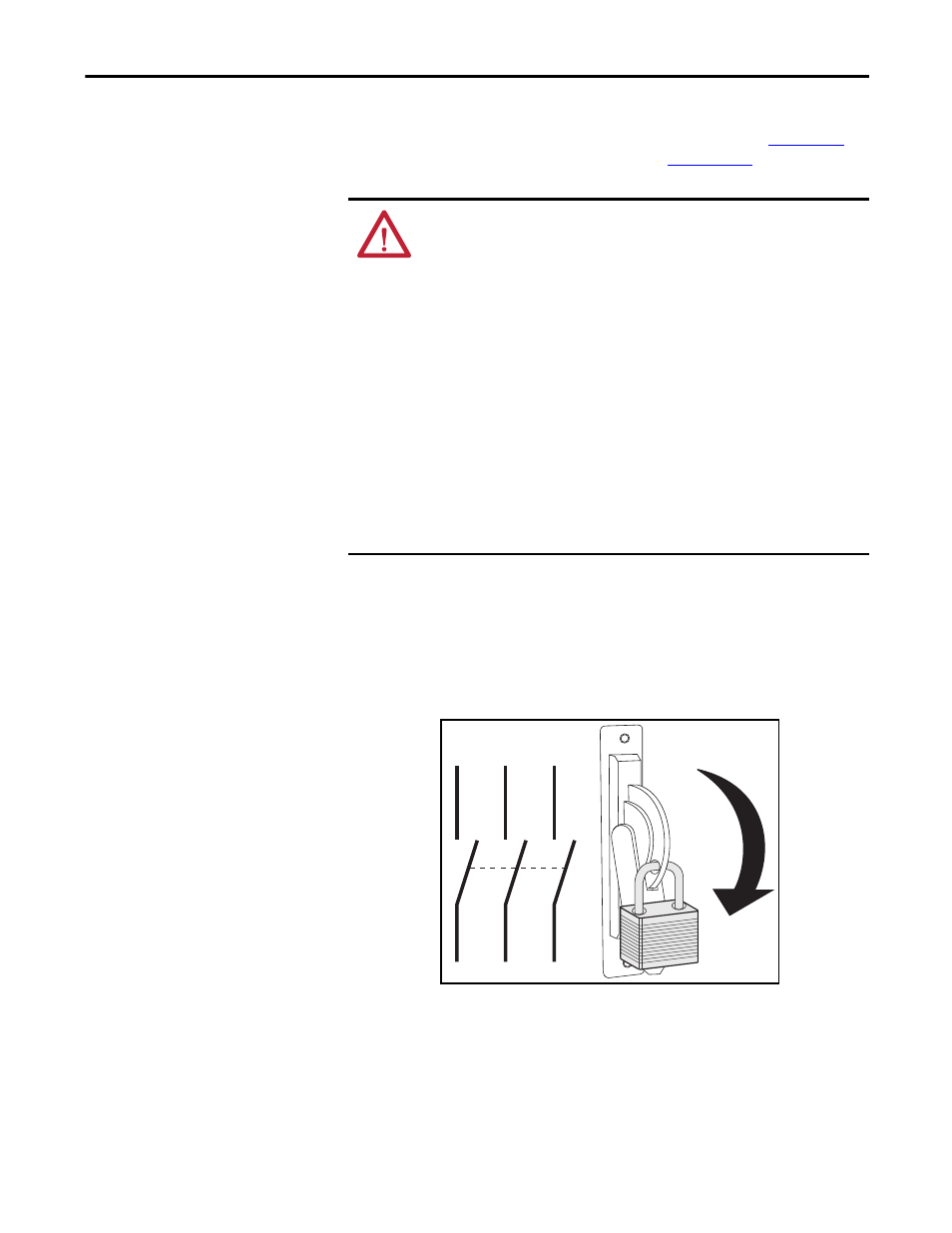

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power terminals.

3. Check the DC bus voltage at the Power Terminals by measuring between

the +DC and –DC terminals, between the +DC terminal and the chassis,

and between the –DC terminal and the chassis. The voltage must be zero

for all three measurements.

ATTENTION: To avoid an electric shock hazard, ensure that all power has

been removed before proceeding. In addition, before servicing, verify

that the voltage on the bus capacitors has discharged. Check the DC bus

voltage at the Power Terminals by measuring between the +DC and -DC

terminals, between the +DC terminal and the chassis, and between the

-DC terminal and the chassis. The voltage must be zero for all three

measurements.

Remove power before making or breaking cable connections. When you

remove or insert a cable connector with power applied, an electrical arc

may occur. An electrical arc can cause personal injury or property damage

by:

• sending an erroneous signal to your system’s field devices, causing

unintended machine motion.

• causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on the module and its

mating connector. Worn contacts may create electrical resistance.

L1

L2

L3

O

I