Chapter 10: maintenance, Overview, Preventive maintenance – RKI Instruments Beacon 410 User Manual

Page 68: Troubleshooting

64 • Overview

Beacon 410 Gas Monitor Operator’s Manual

Chapter 10: Maintenance

Overview

This chapter describes preventive maintenance procedures for the Beacon 410 and how

to replace the AC fuses. It includes a troubleshooting guide for problems you may

encounter with the Beacon 410.

Preventive Maintenance

Preventive maintenance of the Beacon 410 consists of daily, monthly, and quarterly

procedures to ensure that the installed detector heads remain on zero (20.9 for oxygen) in

fresh air and are responsive to the target gas. See the detector head operator’s manuals

for preventive maintenance procedures for each installed detector head.

Troubleshooting

Table 21 describes symptoms, probable causes, and recommended actions for the most

common problems you may encounter with the Beacon 410.

NOTE:

This troubleshooting guide describes Beacon 410 problems only. See the

detector head operator’s manuals for preventive maintenance procedures that

apply to the detector heads installed on your Beacon 410.

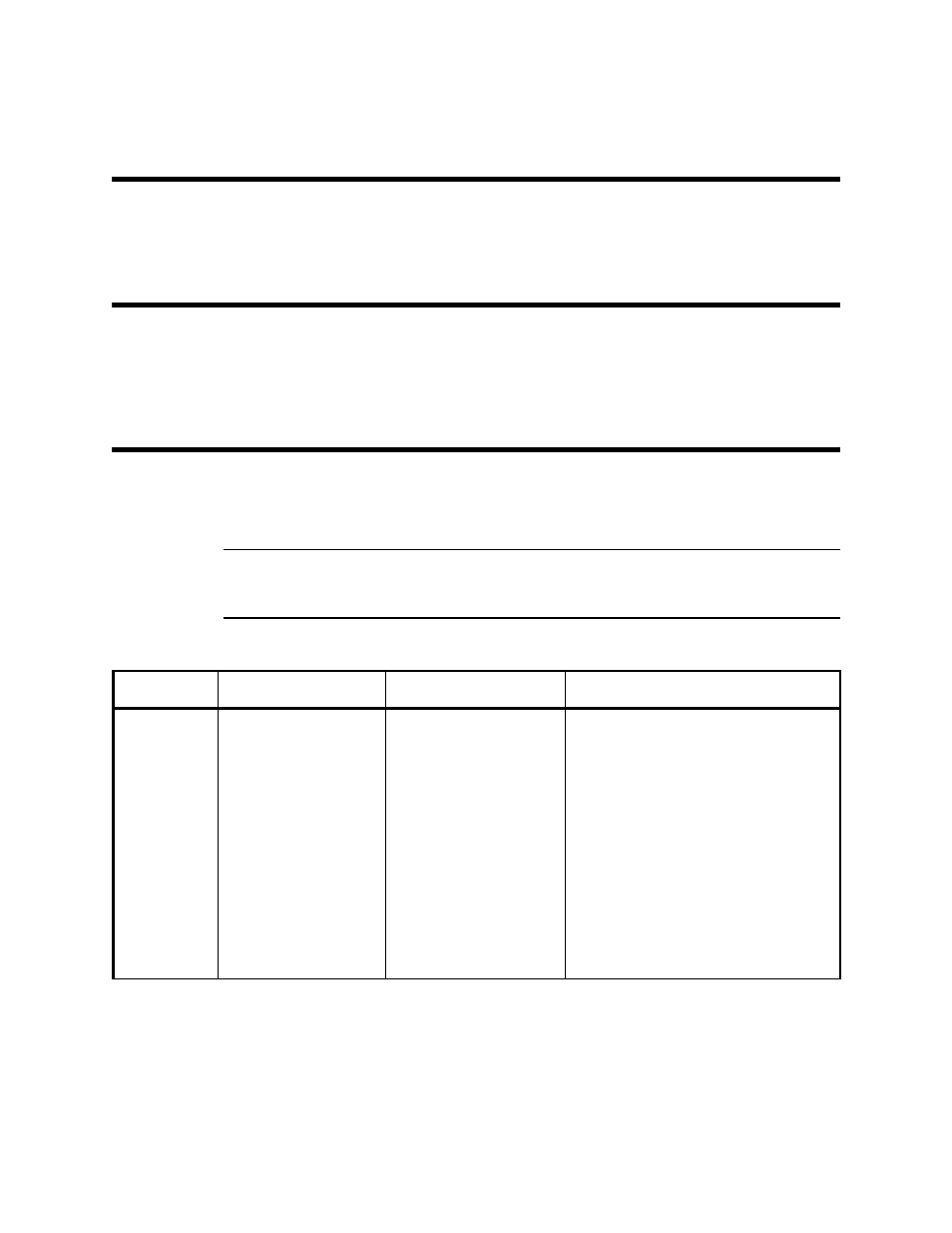

Table 21: Troubleshooting the Beacon 410

Condition

Symptom(s)

Probable Causes

Recommended Action

No Power to

Instrument

and/or

Display

PCB

•

The PILOT light is

off.

•

The display screen

is blank.

•

The power wiring is

disconnected or

misconnected.

•

The AC fuse is blown.

•

The display cable is

disconnected or

misconnected.

1. Verify that the wiring to the power

source is correct and secure.

2. At the Beacon 410, verify that the

wiring to the AC in terminal strip is

correct and secure.

3. Check the continuity of the AC fuses.

4. Verify that the display cable is

connected.

The display (ribbon) cable plugs into a

rectangular connector on the top edge

of the control PCB and on the top

edge of the main PCB (labeled Front

Panel).

5. If the power difficulties continue,

contact RKI for further instruction.