Magna-loc, Ul 580 wind uplift information – Metal Sales Magna-Loc Installation User Manual

Page 26

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

26

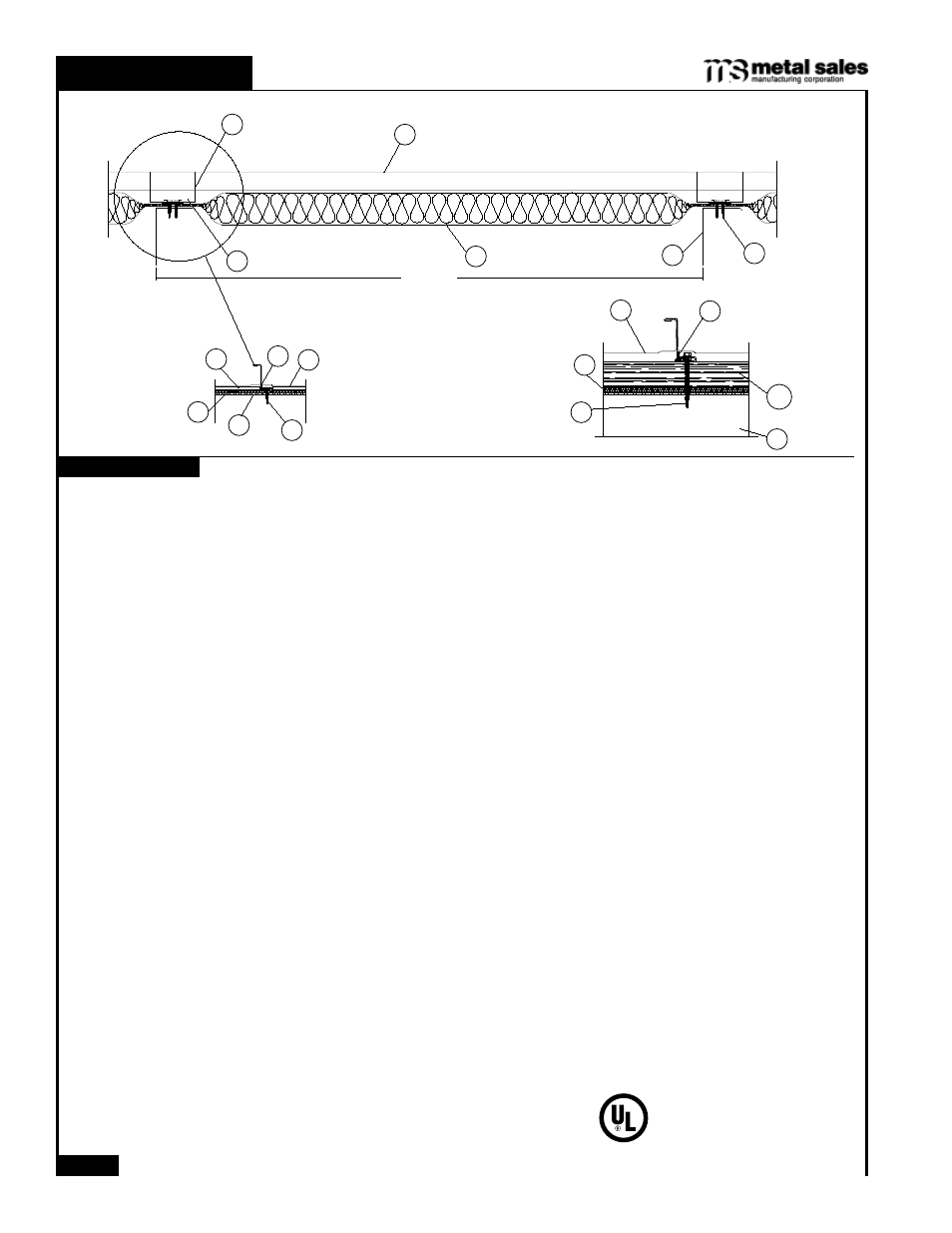

MAGNA-LOC

1. Metal Roof Deck Panels* No. 24 MSG min thick coated steel. Panel width, max 18 in., min 12 in.; rib height 2 in.

Panels continuous over two or more spans. The panel flat area may have optional striations or minor corrugations

placed at various locations in the panel flat area beginning min of 2 in. from side ribs. The upper flange of the panel

rib may be horizontal, or optionally formed down to form an angle of 0 degree to 90 degree between the vertical

segment and the top flange of the rib. End lap to occur adjacent to and within 12 in. of purlin (Item 6) with panels

overlapped 2 in. min. An end lap back-up-plate (Item 2A) to be used. A bead of sealant may be used at panel

end laps and side ribs. Ribs to be seamed with an electric or hand seaming tool to form a flange with a tight hem.

Seaming process to include the upper portion of the Panel Clips (Item 2).

METAL SALES MFG CORP - “Magna-Loc 18”, “Magna-Loc 16”

2. Roof Deck Fasteners* (Panel Clips) Located at side of panels over purlins (Item 6). (Max spacing 60 in. OC).

When wood thermal block (Item 4A) is used, clips to be located on top. Either of the following:

Fixed Clip (Not Shown) - One piece assembly fabricated from No. 22 MSG min thick steel, 3-1/2 in. wide.

Floating Clip - Two piece assembly with a base fabricated from No. 16 MSG min thick steel, 2 in. wide and a

top fabricated from No. 22 MSG min thick steel, 4-5/16 in. wide.

2A. End Lap Back-Up-Plate (Not shown) - No. 16 MSG min thick coated steel channel, 3 in. wide with two 3/8 in. deep

legs. Max length 74 in. Located under the panel end lap (50 ksi min yield strength).

2B. Roof Deck Fasteners*(Cinch Plate) (Optional) - (Not Shown) - width 1-5/16 in., length 18 in. max. Fabricated from

No. 20 MSG min thick stainless steel. Located over end lap.

2C. End Lap Back-Up-Plate (Optional) - (Not shown) - No. 16 MSG min thick coated steel. Width 11, 13 or 19 in.,

length 7 in. Two 3/4 in. by 3/4 in. tabs and a 1 in. deep vertical leg located at up-slope edge of panel. Used with

Item 2A when Item

*2B is not used (50 ksi min yield strength).

3. Fasteners (Screws) For panel clip-to-purlin attachment to be 1/4"-14 by min 1 in. long self drilling, self-tapping

hex-washer-head plated steel screws.

Two fasteners used per clip. Fasteners used at end lap to be one of the

following: No. 1/4-14 by 1 in. long Type AB point, self-drilling, self-tapping hex-washer-head plated or stainless steel

screws or No. 12-14 by 1-1/4 in. long self-drilling self-tapping hex-washer-head plated steel screws. Spacing for 16

in. wide panels to be a 1, 3, 4, 4, 3 in. pattern; spacing for 18 in. wide panels to be a 1-1/2, 3-1/2, 4, 4, 3-1/2, 1-1/2

in. pattern. When optional cinch plate (Item 2B) is used, four fasteners to be required, inserted into factory punched

guide holes.

4. Thermal Spacer (Optional) - Polyisocyanurate - 3/8 in. min, 2-3/8 in. max thick, 4 in. min width, length sized to fit

between panel clips (Item 2).

5. Insulation (Optional) - Any compressible blanket insulation 8 in. max thick before compression, or 6 in. max thick

when located between Thermal Spacer (Item 4) or Thermal Block (Item 4A) and purlin (Item 6).

6. Purlins No. 16 MSG min thick steel ( 50 ksi min yield strength ). Max spacing 60 in. OC.

Refer to General Information, Roof Deck Constructions for items not evaluated.

*Bearing the UL Classification Mark

Construction No. 506

October 16, 2001

Uplift - Class 90

Fire Not Investigated

UL 580 WIND UPLIFT INFORMATION

MAGNA-LOC

1

3

2

4A

5

6

60" MAX

3

1

2

4

6

5

4

2

1

5

6

3

Underwriters Laboratories Inc.

®

LISTED