Lenze MCH Series User Manual

Page 56

52

13435744_EDBMH01_v13

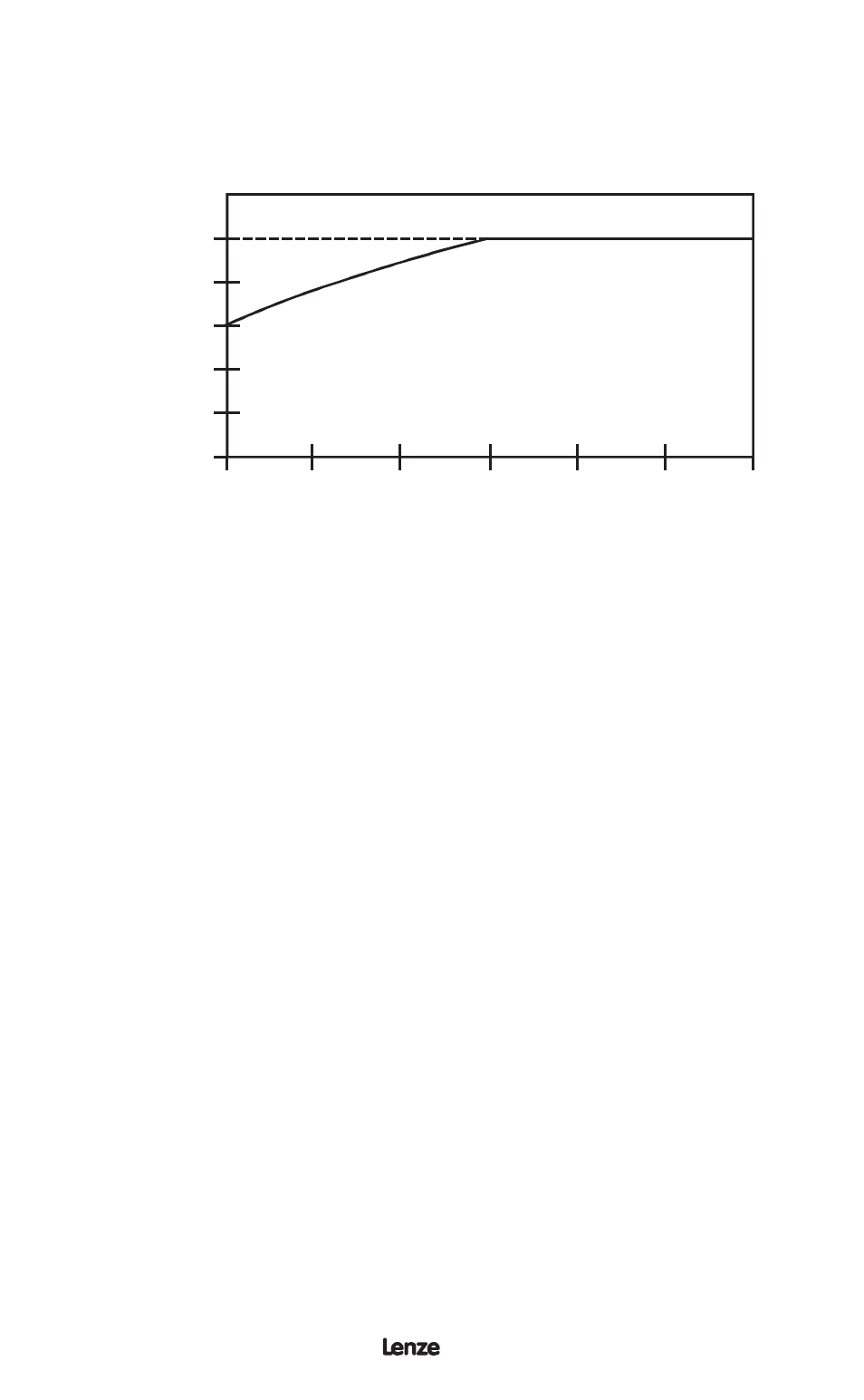

The MCH Series drive has two options for thermal overload protection. One depends

on the speed of the drive while the other does not. The diagram below illustrates the

difference between “speed compensated” and “non-compensated” thermal overload

protection.

FREQUENCY (Hz)

M

AXIMUM C

ONTINUOUS

OUTPUT CURRENT (%)

NON-COMPENSATED

SPEED C

OMPENSA

TED

10

20

30

40

50

60

20

40

60

80

100

The “speed-compensated” thermal overload circuit offers additional protection from high

load conditions at low speeds, where motor cooling is often less effective (e.g., motors

with shaft-mounted fans). As illustrated in the following diagram, the drive reduces the

allowable continuous output current when operating at frequencies less than 30 Hz.

Example 2:

A 480 Vac, 20 HP drive is operating a motor at 10 Hz. From the diagram,

a drive operating at 10 Hz can deliver about 75% of its output current

rating continuously. A 480 Vac, 20 HP drive’s output current rating is 27

Amps. Therefore, the drive would be able to operate continuously at 20

Amps. The drive would also be able to deliver 120% of that value (24

Amps) for one minute before tripping into an OVERLOAD fault.

The “speed compensated” thermal overload is the factory default and should be used

in applications where the motor does not normally experience high loads at low speeds

for extended periods of time.

NOTE 1: The above diagram is based on a MOTOR OVRLOAD setting of 100%. For

lower MOTOR OVRLOAD settings, reduce the % CURRENT values by the

same percentage. For example, if MOTOR OVRLOAD is set to 75%, reduce

the % CURRENT values by 25%. Therefore, the curve shifts down, but the

shape of the curve remains the same.

The “non-compensated” thermal overload circuit allows 100% current continuously, and

120% current for one minute, at all speeds. In the example above, the motor operating

at 10 Hz without “speed-compensated” protection would be allowed to operate

continuously at 27 Amps, and could draw 32.4 Amps for one minute before tripping.

Without sufficient motor cooling, this can result in motor failure due to overheating.

The “non-compensated” circuit is selected by setting Parameter 22 - TORQUE to CONST

/ NO COMP. The “non-compensated” setting should only be used in applications where

the motor is properly cooled at all speeds, or the motor manufacturer has approved the

motor for full-load operation at low speeds.

NOTE 2: The operation of the motor thermal overload circuit is affected by the setting

of Parameter 34 - LOAD MULTIPLY.