Deceleration limits – Lenze MCH Series User Manual

Page 53

13435744_EDBMH01_v13

49

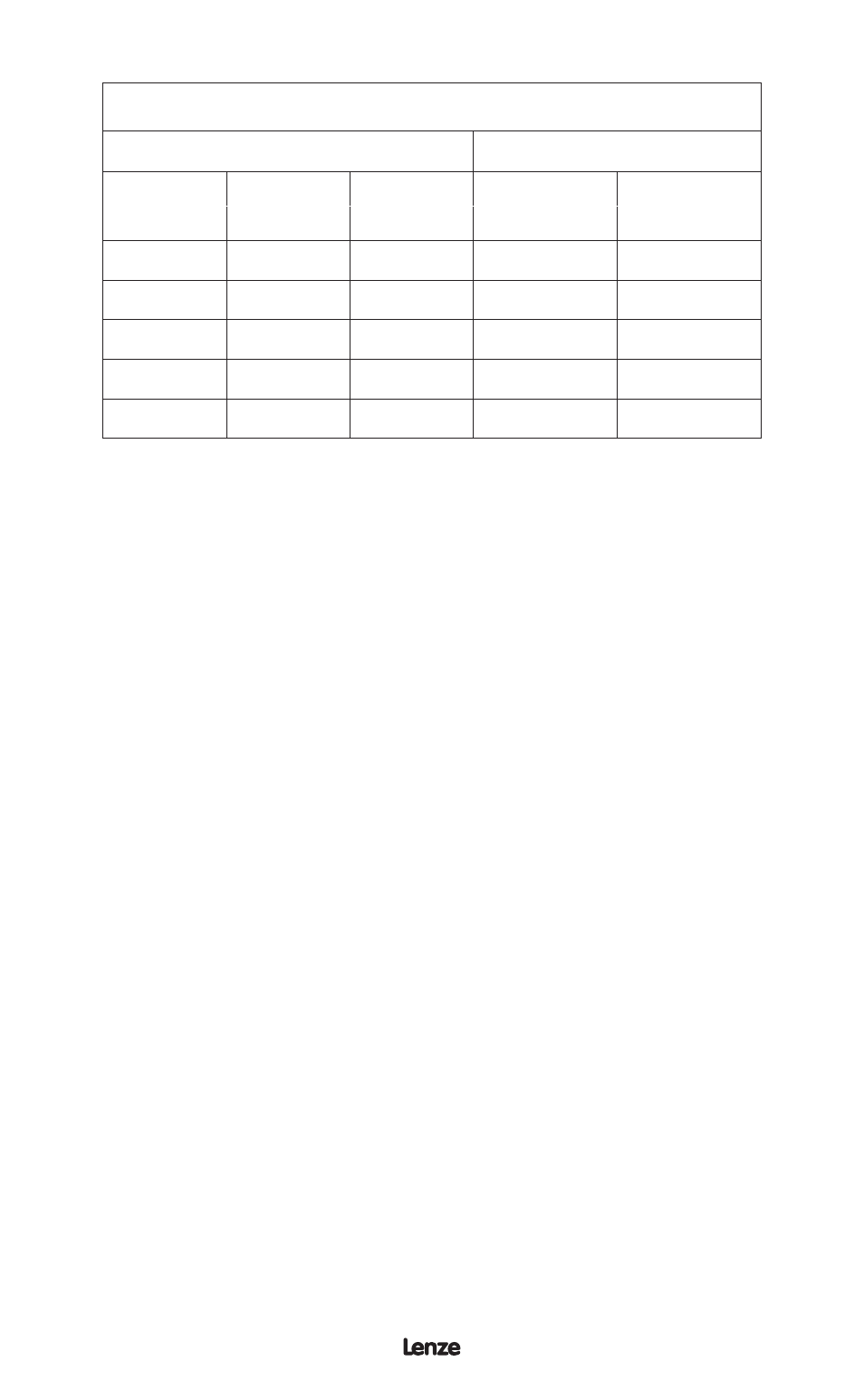

DECELERATION LIMITS

HORSEPOWER / VOLTAGE RATING

RANGE OF ADJUSTMENT

240 / 200 Vac

480 / 400 Vac

590 / 480 Vac

WITHOUT DB

WITH DB

(NOTE 1)

(NOTE 2)

0.25 - 7.5 HP

1 - 7.5 HP

----

0.3 - 3600 SEC

0.1 - 3600 SEC

10 - 15 HP

10 - 20 HP

1 - 7.5 HP

0.5 - 3600 SEC

0.1 - 3600 SEC

20 - 60 HP

25 - 60 HP

10 - 20 HP

1.0 - 3600 SEC

0.2 - 3600 SEC

----

75 - 100 HP

25 - 60 HP

2.0 - 3600 SEC

0.2 - 3600 SEC

----

125 - 250 HP

75 - 200 HP

4.0 - 3600 SEC

0.2 - 3600 SEC

NOTE 1: 240/120 Vac units have the same limits as 240/200 Vac units.

NOTE 2: This parameter can be set as low as the value shown in the WITH DB column.

However, the value shown in the WITHOUT DB column is the operational

limit of a drive without dynamic braking. For example, DECEL can be set as

low as 0.1 seconds on a 10 HP, 480 Vac drive without dynamic braking, but

the actual minimum deceleration time would be 0.5 seconds

If an attempt is made to decelerate a high-inertia load too quickly, the motor will

regenerate voltage back into the drive. This will cause the DC bus voltage to rise, which

can result in a HI VOLTS fault. In order to prevent faulting, the drive will enter DECEL

FREEZE, which halts the deceleration until the DC bus voltage returns to a normal

level. The drive will then begin to decelerate again, and if necessary, will enter DECEL

FREEZE repeatedly to avoid faulting. If a very short deceleration time is programmed,

DECEL FREEZE may not be able to compensate fast enough, resulting in a HI VOLTS

fault.

In applications where very short deceleration times are required on high-inertia loads,

dynamic braking may be required. Consult the factory for more information on the

Dynamic Braking option.

10

MINIMUM FREQ

This parameter defines the lower limit of the drive’s speed range. MINIMUM FREQ is

used in conjunction with MAXIMUM FREQ (Parameter 11) to define the operating range

of the drive.

If MINIMUM FREQ is set to a value above 0.0 Hz, the drive will ramp up from 0.0 Hz

when given a start command. Once running, however, the drive will not operate below

the MINIMUM FREQ setting unless the rotation is changed, or a stop command is

issued and the drive is programmed to ramp to a stop.

If MINIMUM FREQ is set to 0.0 Hz, the drive may be operated in ZERO SPEED mode

(drive is in RUN state, but there is no output to the motor). ZERO SPEED operation can

be used in applications requiring the ability to start and stop the drive using only the

selected speed reference. The drive will start when the speed reference is raised above

0 VDC or 4 mA, and it will stop when the reference is lowered to 0 VDC or 4 mA. Note

that the drive must be initially started using one of the normal start commands (keypad

or terminal strip).