Maximum dc brake voltage – Lenze MCH Series User Manual

Page 54

50

13435744_EDBMH01_v13

11

MAXIMUM FREQ

This parameter defines the upper limit of the drive’s speed range. MAXIMUM FREQ is

used in conjunction with MINIMUM FREQ (Parameter 10) to define the operating range

of the drive.

WARNING!

Consult motor manufacturer before operating motor above rated

frequency. Overspeeding the motor and/or driven equipment can

cause damage to equipment and injury to personnel!

12

DC BRAKE VOLT

DC braking creates a braking torque by injecting DC voltage into the motor. This

parameter sets the magnitude of that DC voltage.

The point at which the drive applies DC braking to the motor depends on which STOP

method is programmed (either COAST or RAMP, refer to Parameter 26 - STOP

METHOD).

If the drive is set to COAST, DC braking is activated when the stop command is given.

In this case, DC braking helps decelerate the motor. This is useful in applications where

a quick deceleration is desired on a load that would normally take a long time to coast

to a stop.

If the drive is set to RAMP, DC braking is activated when the output frequency reaches

0 Hz. In this case, the drive decelerates the load to a near stop and then DC braking is

used to stop and hold the motor. This is useful in applications where the load needs to

be stopped in a certain position. Similar applications with high-inertia loads utilize both

dynamic braking and DC braking. The dynamic braking allows the high-inertia load to be

decelerated quickly, while the DC braking stops the load in the desired position.

Due to heat generated in the motor, DC braking should only be used in applications

where the load is stopped infrequently. In high duty-cycle applications, dynamic braking

is recommended because the heat is dissipated through external resistor banks, rather

than in the motor. When used, DC BRAKE VOLT should be set to the lowest voltage

that provides satisfactory operation in order to minimize motor heating. The maximum

voltage available depends on the voltage rating of the drive.

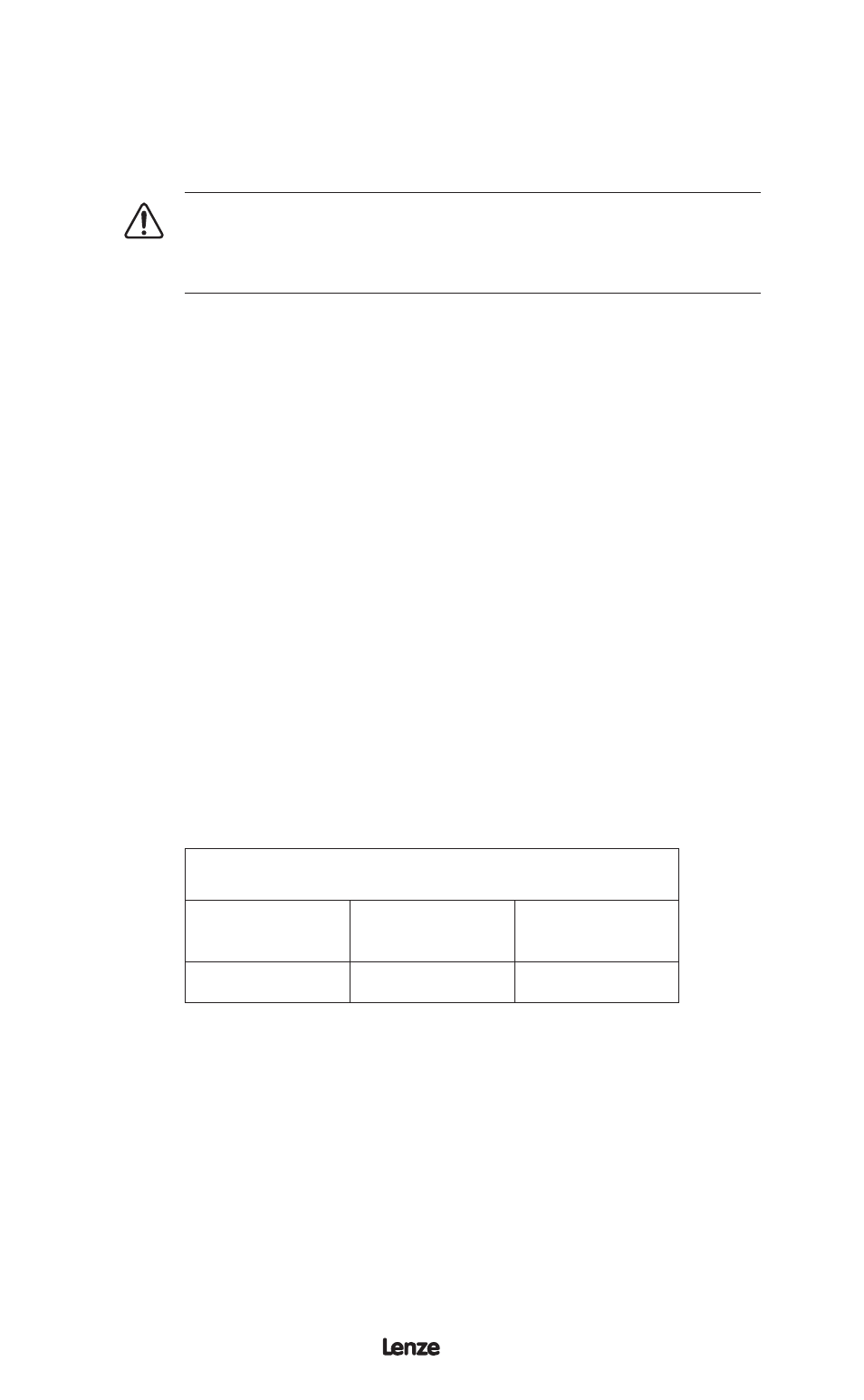

MAXIMUM DC BRAKE VOLTAGE

MODEL MH200

240 / 200 Vac

MODEL MH400

480 / 400 Vac

MODEL MH500

590 / 480 Vac

24 VOLTS

48 VOLTS

59 VOLTS

13

DC BRAKE TIME

This parameter determines the length of time that the DC braking voltage is applied to

the motor. DC BRAKE TIME should be set to the lowest value that provides satisfactory

operation in order to minimize motor heating.

NOTE:

If this parameter is set to 999.9 seconds (the maximum value), the DC braking

will be continuous. If it is set to .0 seconds, it is disabled.