Loop flushing valve, Loop flushing valve -43, Loop flushing spool -43 – JLG 510AJ Service Manual User Manual

Page 85

SECTION 3 - CHASSIS AND TURNTABLE

3121181

– JLG Lift –

3-43

INSPECT COMPONENTS

Inspect the new seal, the motor housing seal bore, and the

sealing area on the shaft for rust, wear, and contamination.

Polish the shaft and clean the housing if necessary.

INSTALLATION

1.

Cover the shaft splines with an installation sleeve to pro-

tect the shaft seal during installation.

2.

Install a new shaft seal with the cupped side facing the

motor. Press seal into housing until it bottoms out. Press

evenly to avoid binding and damaging the seal.

3.

Install seal support washer.

4.

Install snap ring.

5.

Remove the installation sleeve.

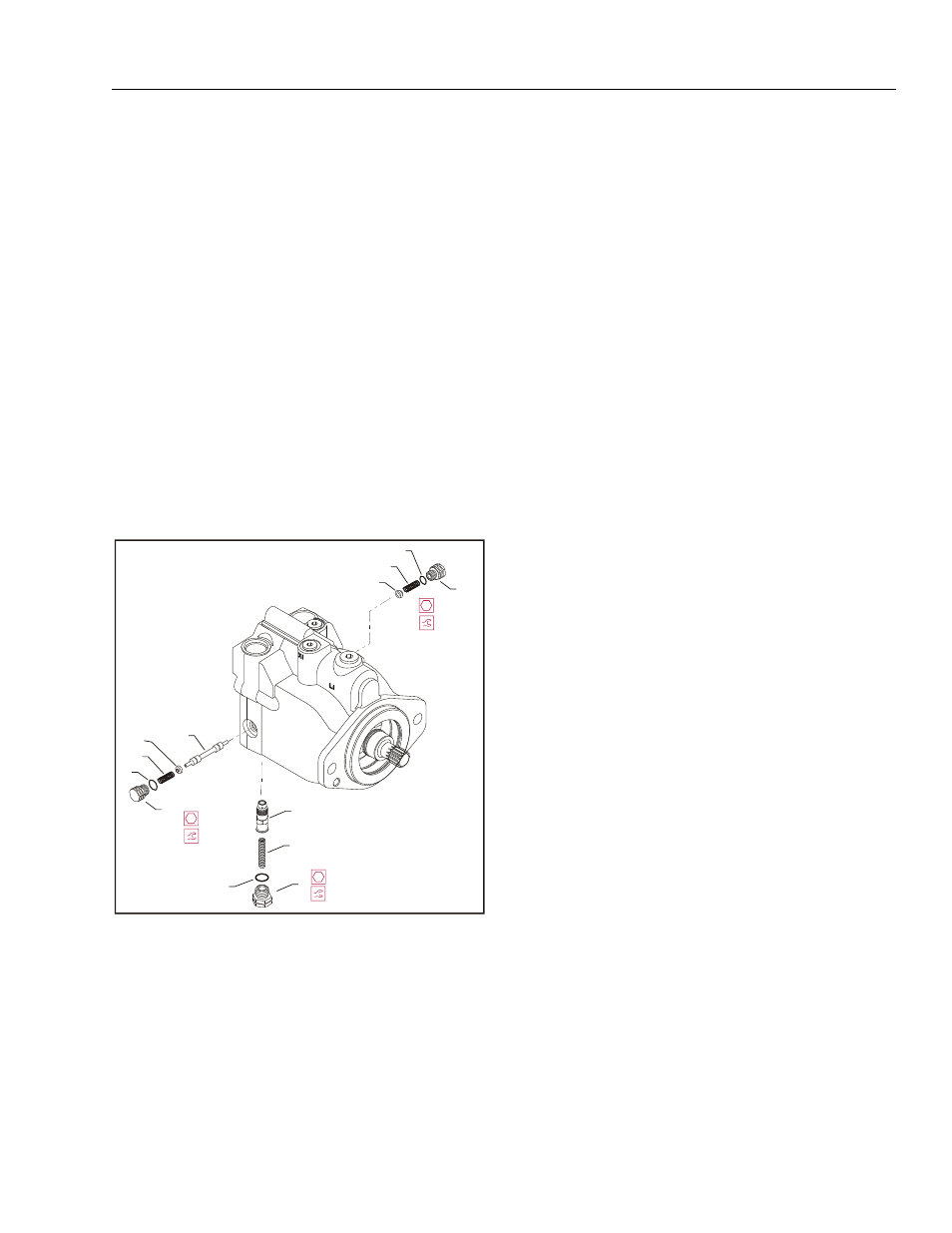

Loop Flushing Valve

REMOVAL

1.

Using a 11/16 in internal hex wrench remove plug (1)

and (2).

2.

Using a 1/4 in hex wrench remove plug (3).

3.

Remove O-rings (4, 5, and 6).

4.

Using pliers, remove centering springs (7, 8, and 9).

5.

Remove spring retaining washers (10 and 11).

6.

Remove shift spool (12).

7.

Remove orifice poppet (13).

INSPECT COMPONENTS

Inspect new O-rings and the sealing area for rust, wear, or con-

tamination. Also check springs and poppet for wear.

INSTALLATION

1.

Install orifice poppet (13).

2.

Install shift spool (12).

3.

Install spring retaining washers onto springs (10 and 11).

4.

Carefully install centering springs (7, 8, and 9).

5.

Install new O-rings (6, 4, and 5).

6.

Using a 1/4 in hex wrench torque plug (3) to 20 ft. lbs.

(27 Nm).

7.

Using a 11/16 in internal hex, torque plugs (2 and 1) to

27 ft.lbs. (37 Nm).

2

6

9

11

1

4

8

10

12

5

3

7

13

(37 Nm)

27 ft.lbs.

11/16 in

(37 Nm)

27 ft.lbs.

11/16 in

(27 Nm)

20 ft.lbs.

5/8 in

1.

Plug

2.

Plug

3.

Plug

4.

O-ring

5.

O-ring

6.

O-ring

7.

Spring

8.

Spring

9.

Spring

10. Washer

11. Washer

12. Shift Spool

13. Orifice Poppet

Figure 3-26. Loop Flushing Spool