Placing pump back into service, 4 variable pump, Ports and pressure gauges – JLG 510AJ Service Manual User Manual

Page 264: Nfpe control, Placing pump back into service -44, Variable pump -44, Ports and pressure gauges -44 nfpe control -44, Recommended gauge size -44, 4 variable pump ports and pressure gauges

SECTION 5 - HYDRAULICS AND HYDRAULIC SCHEMATICS

5-44

– JLG Lift –

3121181

Placing Pump Back Into Service

1.

If shop test stand is available, the following procedure for

testing rebuilt pumps is recommended:

a. Mount pump on test stand making sure that the

proper level of clean oil is available in the reservoir.

Check suction line for leaks and obstructions.

b. Start pump and run for three minutes at zero pres-

sure.

c. Intermittently load pump to 500 P.S.I. for three min-

utes.

d. Intermittently load pump to 1000 P.S.I. for three

minutes.

e. Intermittently load pump to 2000 P.S.I. for three

minutes.

f.

Remove pump from test stand and check for free-

ness of drive shaft. Check pump for signs of external

leakage.

2.

If shop test stand is not available, the following procedure

for testing rebuilt pumps is recommended:

a. For engine driven pumps, mount pump on equip-

ment and run pump at 1/2 engine speed at zero

pressure for three minutes.

b. By operating control valve, build pressure intermit-

tently for three minutes.

c. Increase engine speed to full throttle and build

pressure intermittently for three minutes.

d. Stop engine and check pump for external leaks.

5.4

VARIABLE PUMP

Ports and Pressure Gauges

Proper servicing of pumps and motors requires that pressure

be measured and monitored at various points in the hydraulic

circuit. The Series 42 pump has several locations at which to

take these measurements. The following outlines show the

locations of the various gauge ports. The following table

shows the recommended gauge size and the fitting size for

each port.

NFPE Control

The 3-position FNR control and the electric and hydraulic non-

feedback proportional (NFPE and NFPH) controls are non-

feedback type controls. The FNR and NFPE controls consist of

modules mounted on the pump housing. The hydraulic input

for NFPH is received through ports on the top of the pump [9/

16–18 SAE O-ring fitting].

The non-feedback controls are set at the factory. The control

modules can be removed to clean the ports and change the O-

rings.

The orifice plugs for the FNR and NFPE are located inside the

servo piston covers. The orifice plugs for the NFPH are located

in the NFPH ports. Orifice plugs may be cleaned or replaced.

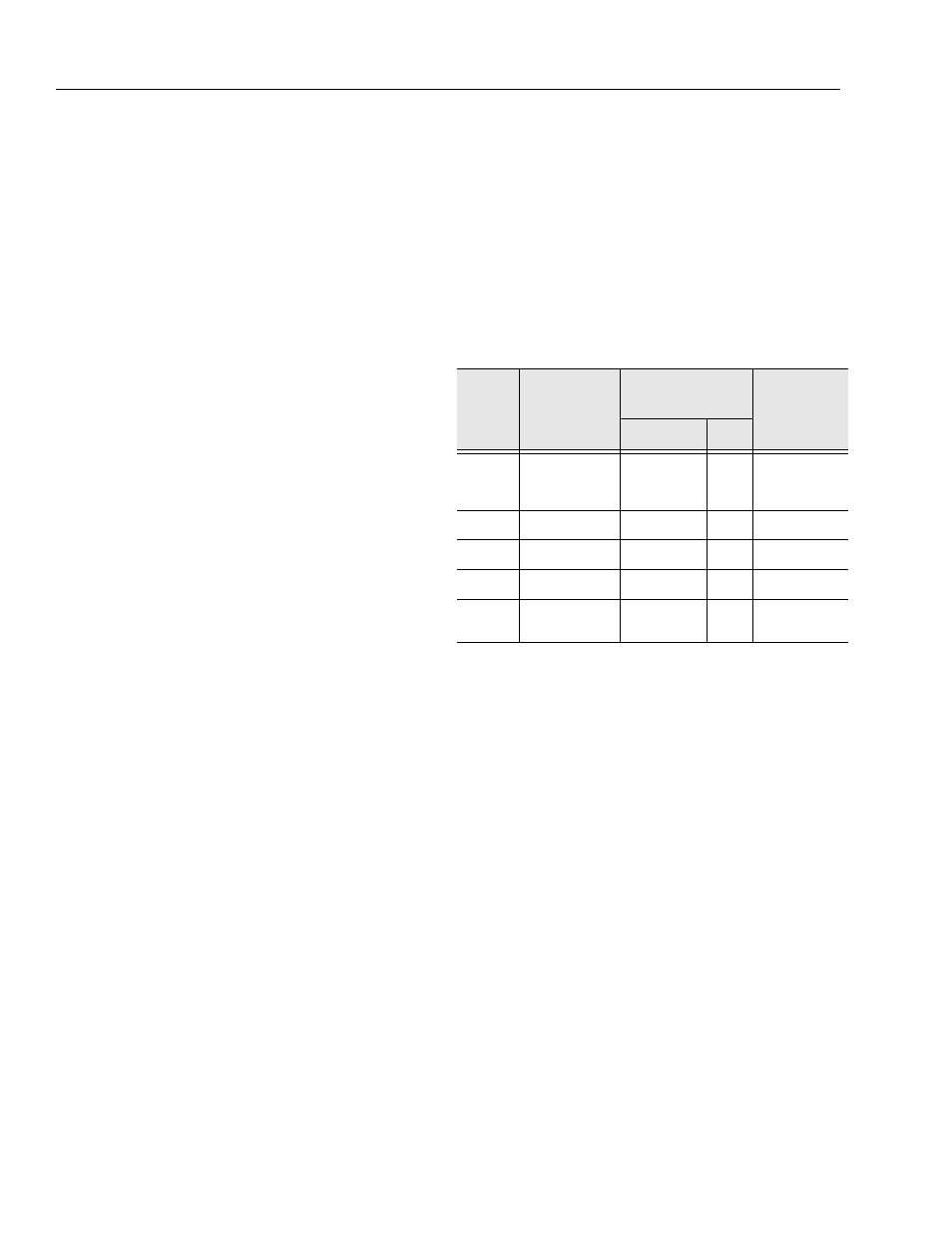

Table 5-2. Recommended Gauge Size

Gauge

Port

Name

Pressure

Measured

Recommended Gauge

Size

Fitting

PSI

Bar

M1 & M2

System

Pressure

Ports A & B

10000

600

9/16-18

ORF

M3

Charge

1000

60

3/4-16

ORF

M4 & M5

Servo

1000

60

9/16-18

ORF

L1 & L2

Case

500

35

1-1/16-12

ORF

S

Charge Pump

Inlet Vacuum

30 in. Hg Vac.

1

1-1/16-12

ORF