Spindle-brake disassembly, Spindle-brake disassembly -8, Spindle brake disassembly -8 – JLG 510AJ Service Manual User Manual

Page 50

SECTION 3 - CHASSIS AND TURNTABLE

3-8

– JLG Lift –

3121181

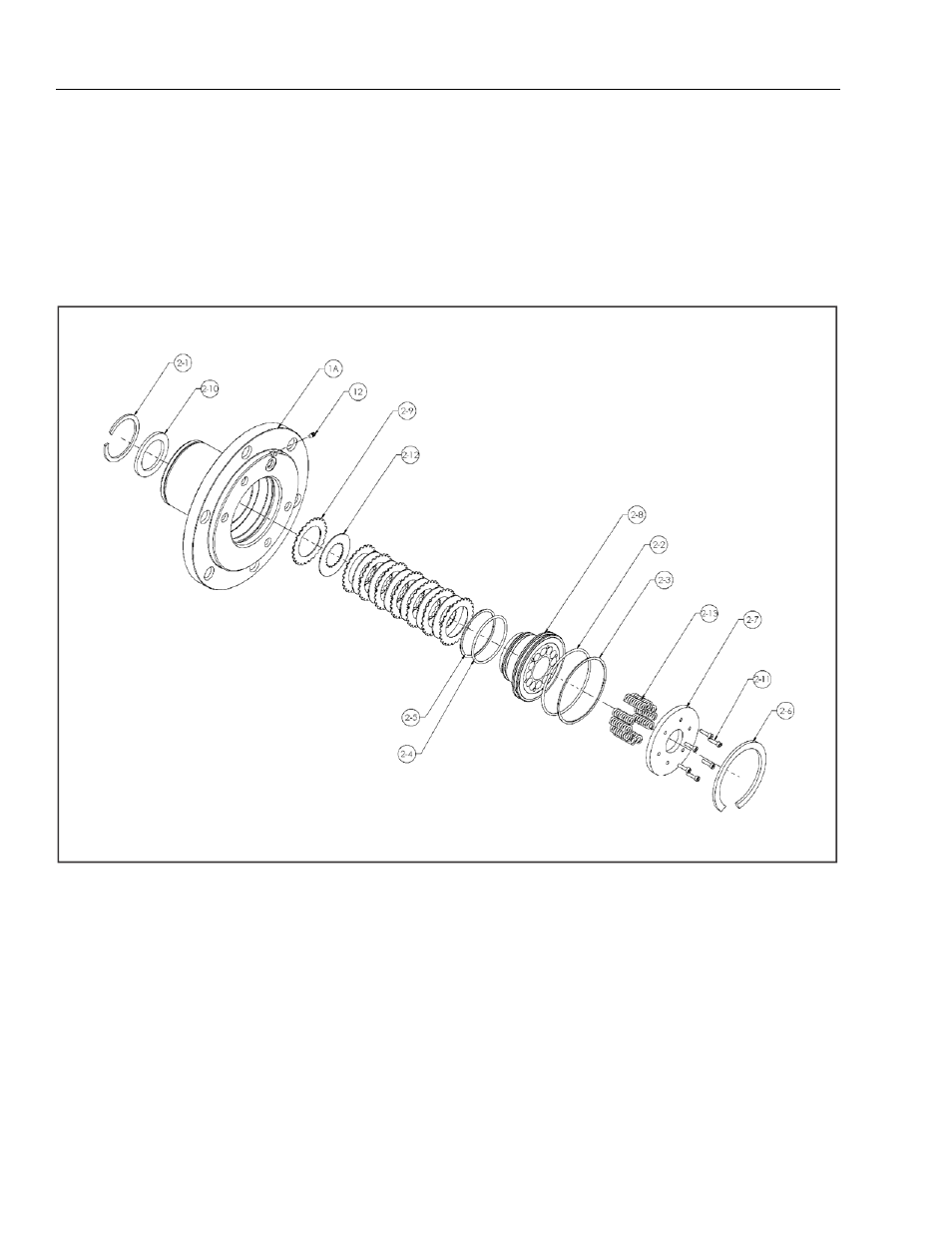

Spindle-Brake Disassembly

NOTE:

This procedure applies only to units with integral input

brake (2).

NOTE:

For this procedure, use the Brake Assembly Drawing, which

will show the proper balloon numbers for the individual

brake components. In the following instructions, if the

number has a “-” between two numbers, it refers to the

Brake Assembly Drawing only and NOT the Torque Hub

Assembly Drawing.

NOTE:

The Pressure Plug (12) requires a special tool for installa-

tion. It is not recommended to remove this plug unless it is

leaking. The plug is called a Koenig Expander. The installa-

tion tool is not supplied by Fairfield manufacturing, but

can be supplied by the manufacturer of the Koenig

Expander, Sherex Industries, or one of their distributors.

1-A. Spindle

2-2. O-ring

2-5. Back-up Ring

2-8. Piston

2-11. Capscrew

12. Pressure Plug

2-3. Back-up Ring

2-6. Internal Circlip

2-9. Stator

2-12. Rotor

2-1. Internal Circlip

2-4. O-ring

2-7. End Plate

2-10. Spacer

2-13. Compression Spring

Figure 3-6. Spindle Brake Disassembly