JLG X17J Plus Operator Manual User Manual

Page 130

BOOM LIFT MODELS X17JPLUS

JLG

126

X17JPR0020413

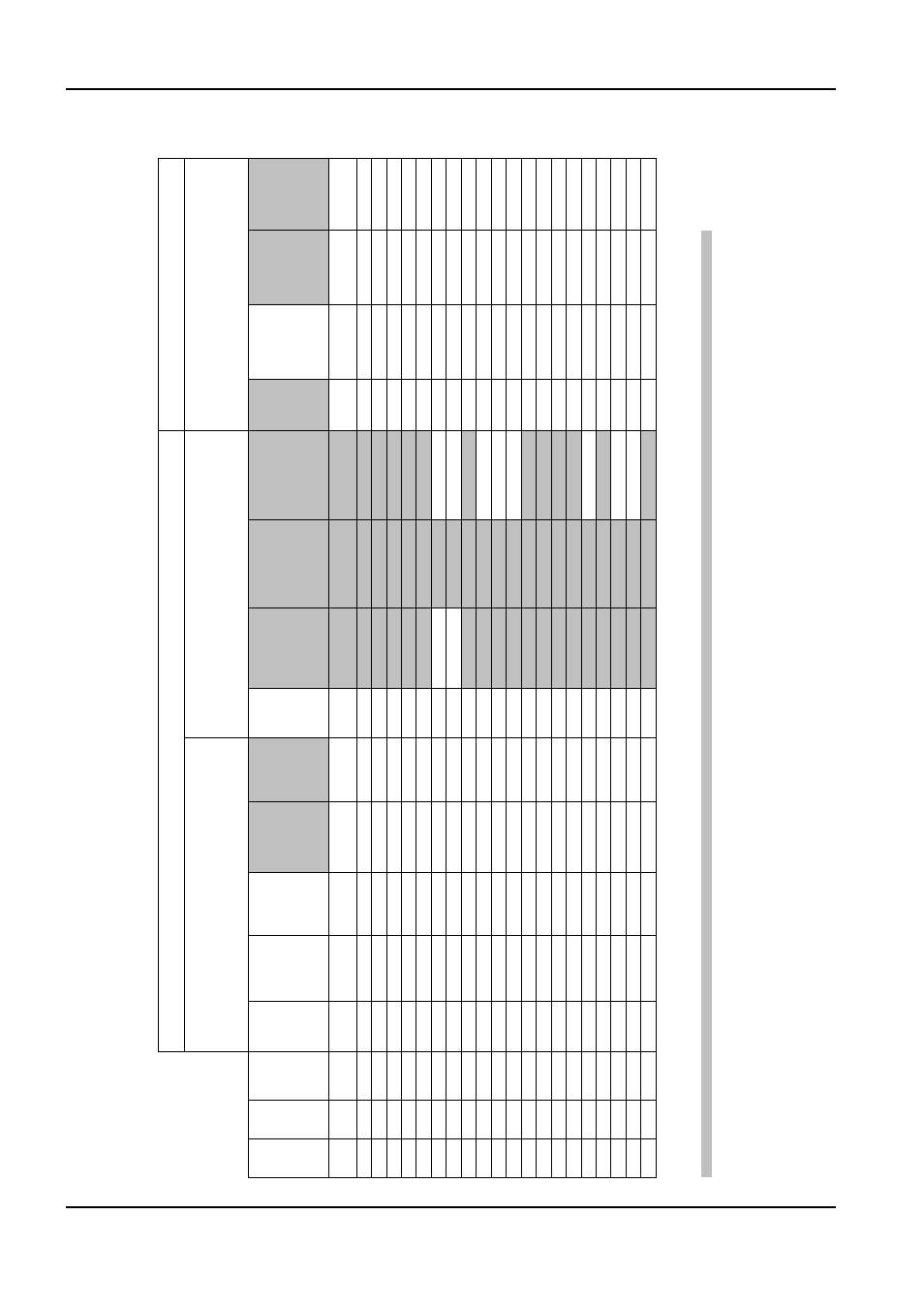

Size

PITCH

Tensile

Stress

Area

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

Torque

(Lub)

Torque

(Loctite® 262

TM

OR Vibra-

TITE

TM

131

)

Torque

(Loctite®

242

TM

or 271

TM

OR Vibra-

TITE

TM

111 or

140

)

Clamp

Load

Torque

(Dry or Loctite®

263

TM

)

K = 0.20

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR

Vibra-TITE

TM

111 or

140)

K= 0.18

Torque

(Loctite® 262

TM

OR

Vibra-TITE

TM

131)

K=0.15

Clamp Load

See Note 4

Torque

(Dry or Loctite®

263

TM

)

K = .17

Torque

(Lub OR Loctite®

242

TM

or 271

TM

OR Vibra-TITE

TM

111 or 140)

K = .16

Torque

(Loctite® 262

TM

OR Vibra-TITE

TM

131)

K = .15

Sq mm

KN

[N.m]

[N.m]

[N.m]

[N.m]

KN

[N.m]

[N.m]

[N.m]

kN

[N.m]

[N.m]

[N.m]

3

0,5

5,03

2,19

1,3

1,0

1,2

1,4

3,13

3.5

0,6

6,78

2,95

2,1

1,6

1,9

2,3

4,22

4

0,7

8,78

3,82

3,1

2,3

2,8

3,4

5,47

5

0,8

14,20

6,18

6,2

4,6

5,6

6,8

8,85

6

1

20,10

8,74

11

7,9

9,4

12

12,5

12,5

13

12

11

7

1

28,90

12,6

18

13

16

19

18,0

25

23

19

18,0

21

20

19

8

1,25

36,60

15,9

26

19

23

28

22,8

37

33

27

22,8

31

29

27

10

1,5

58,00

25,2

50

38

45

55

36,1

70

65

55

36,1

61

58

54

12

1,75

84,30

36,7

88

66

79

97

52,5

125

115

95

52,5

105

100

95

14

2

115

50,0

140

105

126

154

71,6

200

180

150

71,6

170

160

150

16

2

157

68,3

219

164

197

241

97,8

315

280

235

97,8

265

250

235

18

2,5

192

83,5

301

226

271

331

119,5

430

385

325

119,5

365

345

325

20

2,5

245

106,5

426

320

383

469

152,5

610

550

460

152,5

520

490

460

22

2,5

303

132,0

581

436

523

639

189,0

830

750

625

189,0

705

665

625

24

3

353

153,5

737

553

663

811

222,0

1065

960

800

220,0

900

845

790

27

3

459

199,5

1080

810

970

1130

286,0

1545

1390

1160

286,0

1315

1235

1160

30

3,5

561

244,0

1460

1100

1320

1530

349,5

2095

1885

1575

349,5

1780

1680

1575

33

3,5

694

302,0

1990

1490

1790

2090

432,5

2855

2570

2140

432,5

2425

2285

2140

36

4

817

355,5

2560

1920

2300

2690

509,0

3665

3300

2750

509,0

3115

2930

2750

42

4,5

1120

487,0

4090

3070

3680

4290

698,0

5865

5275

4395

698,0

4985

4690

4395

4. CLAMP LOAD LISTED FOR SHCS IS SAME AS GRADE 8 OR CLASS 10.9 AND DOES NOT REPRESENT FULL STRENGTH CAPABILITY OF SHCS. IF HIGH

ER LOAD IS REQUIRED, ADDITIONAL TESTING IS REQUIRED.

*3. ASSEMBLY USES HARDENED WASHER OR FASTENER IS PLACED AGAINST PLATED STEEL OR RAW ALUMINUM

Spec #4150701

Values for Zinc Yellow Chromate Fasteners (Ref 4150707)

CLASS 10.9 METRIC (HEX HEAD) BOLTS

CLASS 10 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS M3 - M5*

CLASS 8.8 METRIC (HEX HEAD) BOLTS

CLASS 8 METRIC NUTS

CLASS 12.9 SOCKET HEAD CAP SCREWS

M6 AND ABOVE*

NOTES: 1. THESE TORQUE VALUES DO NOT APPLY TO CADMIUM PLATED FASTENERS

2. ALL TORQUE VALUES ARE STATIC TORQUE MEASURED PER STANDARD AUDIT METHODS TOLERANCE =

±

10%

Torque Specs