Installation instruc tio ns – Poison Spyder JK CRUSHER CORNERS User Manual

Page 2

INSTALLATION INSTRUC

TIO

NS

Poison Spyder Customs • JK CRUSHER CORNERS INSTALL

Page 2

©2013 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

Steps 3 through 12 pertain to Crusher Corners

with LED taillight holes or no taillight holes. If

installing Crusher Corners made for use with the

stock taillights, skip Steps 4 through 6.

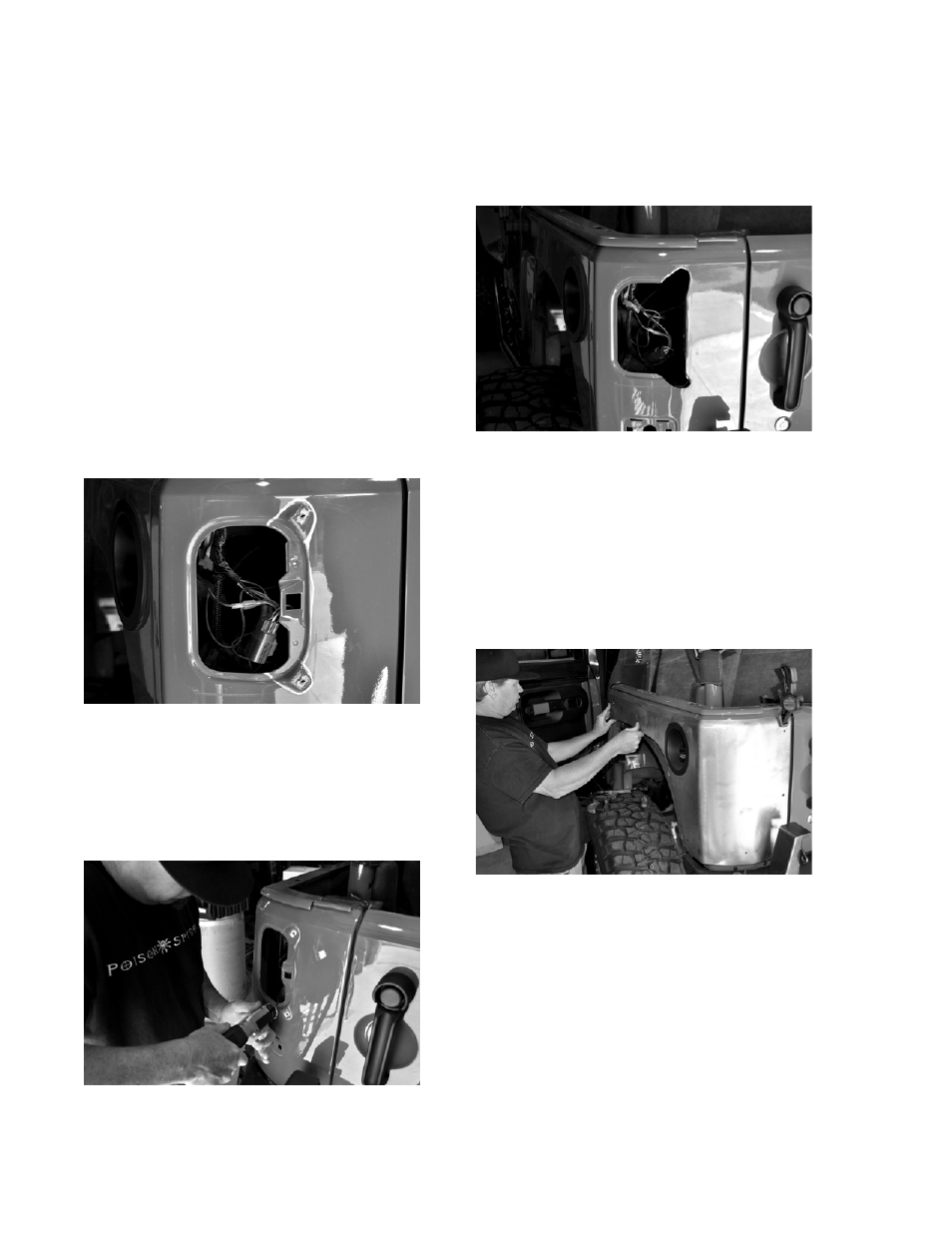

4. Observe the Jeep’s body sheetmetal

around the taillight opening. Note that there

are two raised areas in the upper right and

lower right corners (for the driver’s side

taillight--opposite for the passenger side),

where the threaded inserts for the taillights

are installed. These raised areas, along with

the indented flange section between them

along the right vertical edge of the taillight

hole, will have to be removed for proper

fitment of the Crusher Corner and clearance

for the LED taillight. Use a fine-tip felt marker

to outline the area to be removed, as shown

in Figure 3.

FIGURE 3

5. Use the tools of your choice to cut the

body sheetmetal along your cut mark. Note

that part of the cut goes through double-

thick sheetmetal and may be difficult to get

through. A pneumatic body saw or cut-off

wheel may be ideal for this task.

FIGURE 4

6. Use a file or sander to smooth the edges of

the cut sheetmetal. It is important to remove

any burrs or sharp edges which may snag,

fray or cut electrical wires over time. Use

some touch-up paint or clear-coat to seal

the bare metal around the edge of the cut, to

protect it from rust in the future.

FIGURE 5

7. Place the driver’s side Crusher Corner over

the corner of the Jeep. The Crusher Corner

will slip snugly over the fuel filler trim piece,

assisting with aligning it. Use a measuring

tape to ensure that the distance between the

top edge of the Crusher Corner and the top

edge of the Jeep’s tub is the same from front

to back, and securely clamp the Crusher

Corner into place.

FIGURE 6

It is extremely important to ensure that the

Crusher Corner is securely clamped into

place, that it won’t “walk” or loosen the

clamps once you begin drilling.

8. Use the 5/16” bit and drill motor to drill

through the Jeep’s outer sheetmetal at each

of the hole locations in the Crusher Corner,

using the Crusher Corner itself as your drill

guide. If the Crusher Corner shifts or the

clamps loosen while you’re drilling, stop

drilling and re-align the Crusher Corner and