Installation instruc tio ns – Poison Spyder JK ROCKBRAWLER REAR BUMPER WITH TIRE CARRIER User Manual

Page 4

INSTALLATION INSTRUC

TIO

NS

©2014 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

Poison Spyder Customs • JK ROCKBRAWLER REAR BUMPER

Page 4

15. Wearing a latex or nitrile glove, use your

fingers to apply a light sheen of grease to the

bare metal surfaces of the inside of the tire

carrier hinge housing and bearing races, as

well as the hinge spindle on the bumper (do

not coat the threads for the spindle nut). This

will help discourage rust formation on these

bare metal surfaces.

16. Insert a Tapered Roller Bearing into the

pre-installed Lower Race, inside the Hinge

Housing. Ensure that it seats correctly and

“feels right” in the race. Excess grease may

hold it in place temporarily, but it may be

helpful to turn the tire carrier upside down

until the next step is completed.

17. Use a bearing seal driver tool to carefully

install the grease seal into the bottom of the

hinge housing. If the proper tool is not available,

the step may be performed by carefully using

a large socket of the approximate diameter

of the seal and a soft dead-blow hammer to

work the seal into its seat. Be very careful

to drive the seal in evenly, do not let it get

misaligned while driving it in.

18. Install the Tire Carrier onto the bumper,

carefully guiding the hinge housing down

over the hinge spindle. Be careful not to

damage the grease seal when lowering the

tire carrier on to the spindle. There is a very

tight-tolerance slip-fit between inner diameter

of the tapered roller bearing and its seating

surface on the spindle. Be careful not to

let the bearing get misaligned as you lower

the carrier onto the bumper. Have a friend

support the opposite end of the tire carrier

during this and the next two steps.

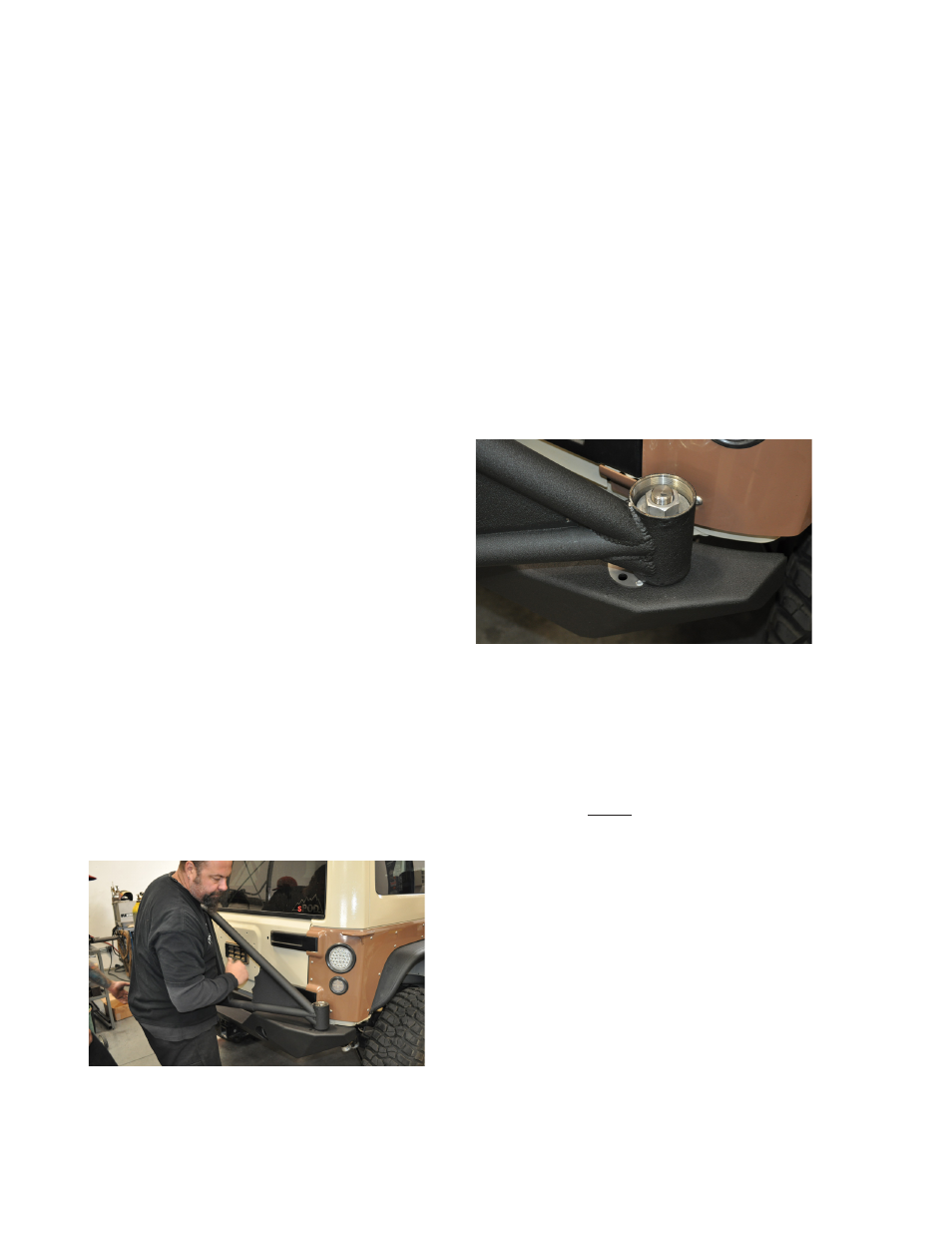

FIGURE 8

19. Install the remaining Tapered Roller

Bearing by dropping it down over the hinge

spindle, narrow end pointed downward.

Carefully slide it down the spindle until it is

seated into the upper race.

20. Apply some anti-sieze thread lubricant to

the threads on the spindle. Install the large 1”

Flat Washer next on the spindle, followed by

the 1”-14 Grade C All-Metal Lock Nut. Tighten

the lock nut until it just touches the washer and

bearing, then have your friend slowly swing

the tire carrier back and forth as you tighten

the lock nut the rest of the way. We can not

supply a torque specification for this nut, just

get it as tight as it takes to properly seat the

bearings and provide smooth operation of

the tire swing without any “play”. You may

need to re-tighten this nut several times until

it permanently seats.

FIGURE 9

21. Install the Hinge Cap O-Ring onto the

outside of the threads of the Billet Hinge

Cap, just under the head of the cap (NOTE:

this may have already been done prior to

shipment).

22. Thread the Hinge Cap onto the Hinge

Housing and lightly tighten with a 2-12”

wrench, socket with ratchet or big-ass

crescent wrench. Note that you may have to

remove it in later steps to further tighten the

spindle lock nut, so don’t fully tighten the cap

until installation is complete.

23. Install the Lock Pin Assembly into the

provided housing (on the side of the hinge

bearing housing). Use an open-end wrench

to carefully tighten the hex head of the pin

assembly.