Installation instruc tio ns – Poison Spyder JK ROCKBRAWLER REAR BUMPER User Manual

Page 2

INSTALLATION INSTRUC

TIO

NS

©2014 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

Poison Spyder Customs • JK ROCKBRAWLER REAR BUMPER

Page 2

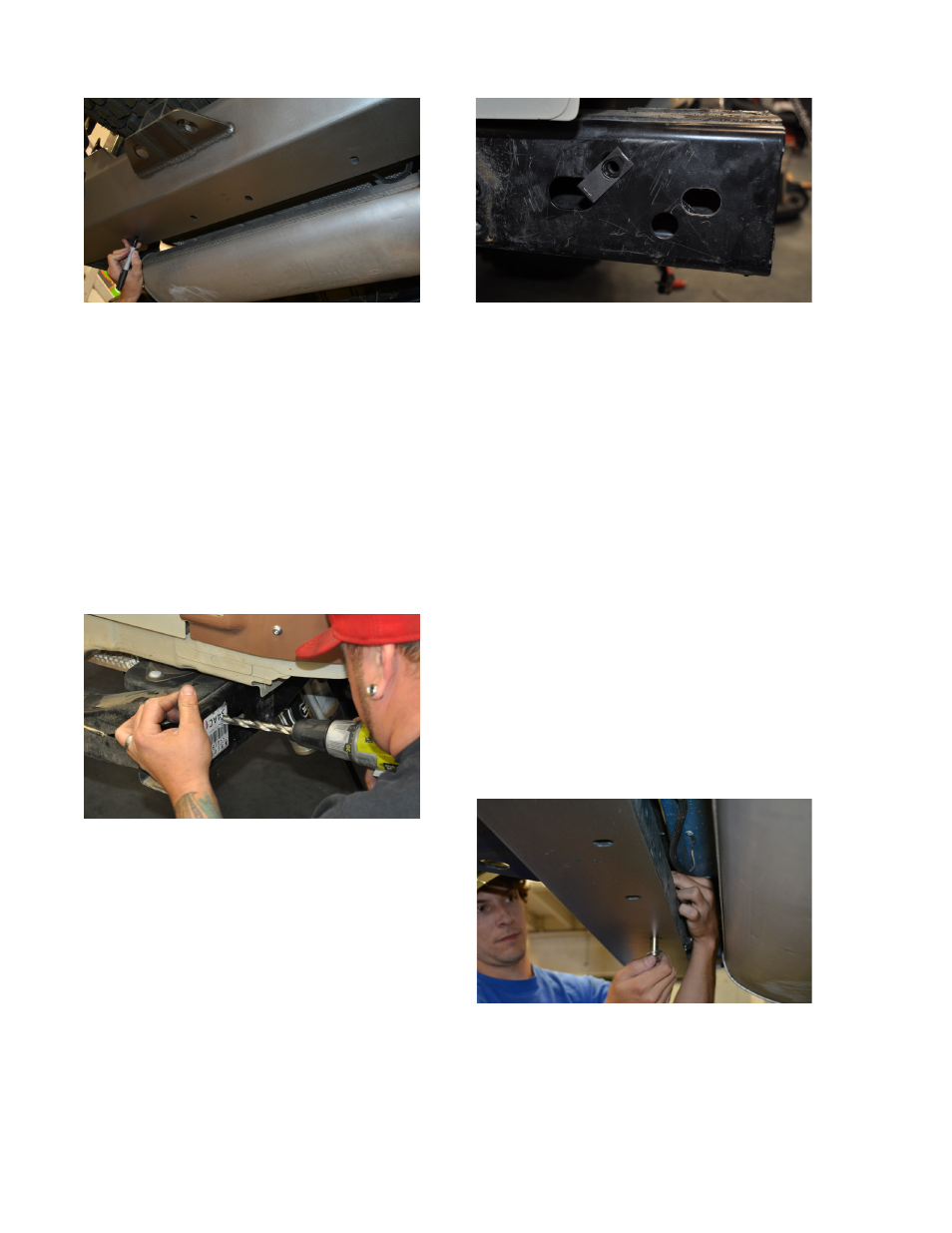

FIGURE 3

6. Remove the bumper from the Jeep.

7. Drill upward through the crossmember,

at the hole location marked in the previous

step. Start with a smaller drill size such as

1/4”, then step up to the 1/2” bit for the final

hole size. Drill through both the bottom and

top surfaces of the bumper, trying to hold the

drill perpendicular so the holes are vertically

aligned.

8. Drill the third bolt hole on the sides of each

frame rail to 1/2”. It is best to start with a

smaller drill size such as 1/4”, then step up to

the 1/2” size bit.

FIGURE 3

9. Apply touch-up paint to the bare metal

around the edge of the holes that were drilled

in the previous steps. Properly coating these

areas at this time will help to prevent rust in

the future.

10. Insert a 3/8-16 Clip Nut through the oblong-

shaped hole in the frame rail, and clip it into

the new hole just drilled. Make sure the

extruded thread barrel of the clip nut points

inward. Do this on both frame rails.

FIGURE 4

11. Reinstall the RockBrawler™ bumper

using the OE hardware in the two original

bolt locations on the sides of the frame rail,

and a supplied 3/8-16 X 1 Gr8 Hex Head

Cap Screw with 3/8 Flat Washer in each of

the new bolt locations on the outside of the

frame rails. Note that both the bumper’s

mount flanges are inserted between the

outside of the frame rail and the sway bar

bracket.

12. Insert the 1/2-13X4-1/4 Gr8 Hex Head Cap

Screws into the two outside holes along the

underside of the bumper, with a 1/2 Gr8

Flat Washer under the bolt head. Insert

the bolt up through the holes in the bumper

and both top and bottom surfaces of the

crossmember. Secure them with a 1/2-13

Gr8 Nylon Insert Lock Nut and 1/2 Gr8 Flat

Washer, where they protrude through the top

of the crossmember. You may have to do

this by feel, as the nuts and washers will be

threaded on inside the bumper shell,

FIGURE 5

13. Once the entire bumper is mounted and

tested for proper fitment, remove the bumper

for paint or powder coat. If painting yourself,

careful preparation will make a big difference

in the quality and longevity of your paint

job, even using “rattle can” aerosol paints.