Discharge valves difficult, Water in pump gearbox, Rotation symptoms – Hale MBP Booster User Manual

Page 61

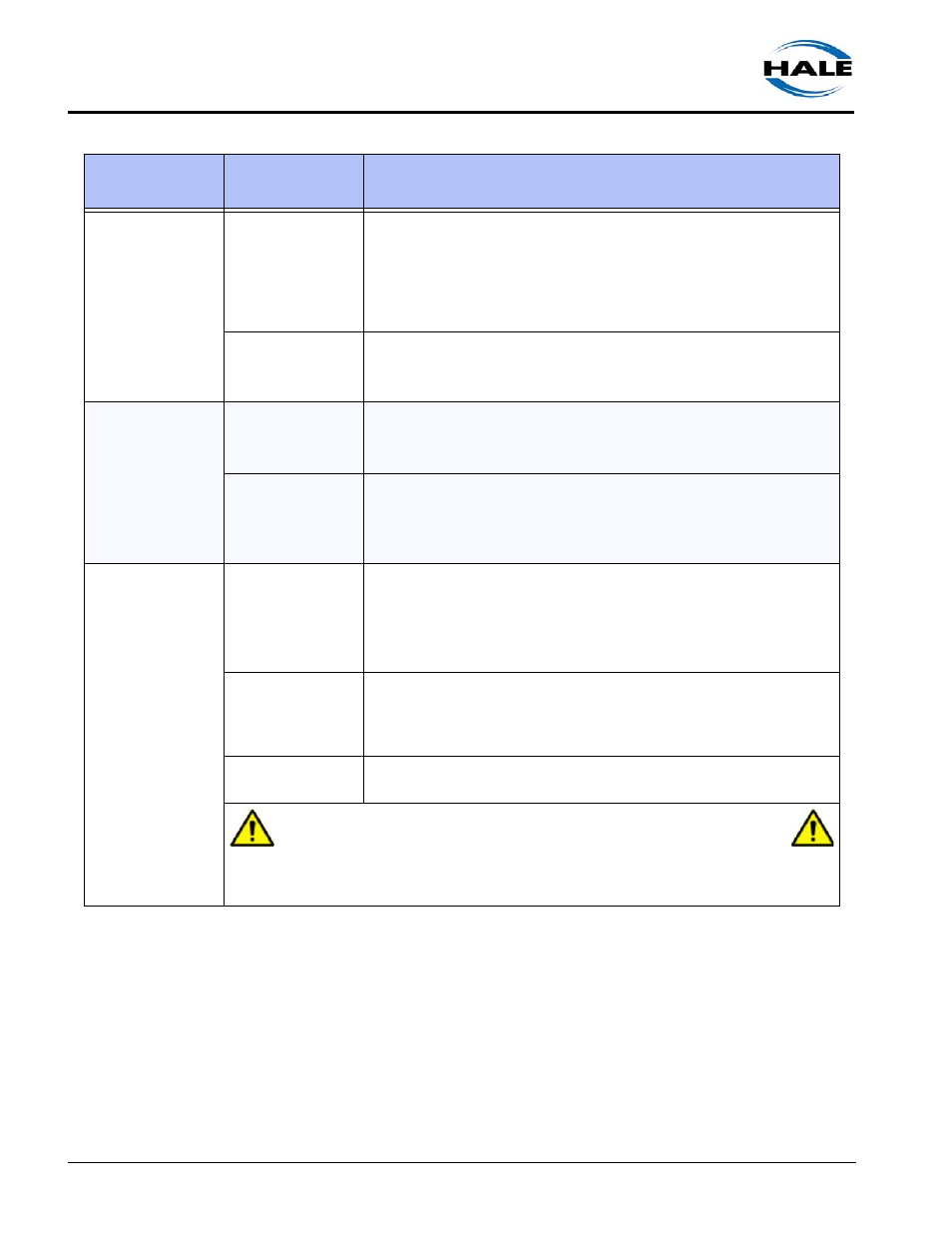

❑ Troubleshooting

60

Silencer Series Booster Pump, p/n: 029-0020-83-0

DISCHARGE

VALVES DIFFI-

CULT TO OPER-

ATE

Lack of lubrication

• Recommended weekly lubrication of discharge and suction valve.

• Use a good grade petroleum based silicone grease.

• Foe Hale Products, SVS Valves, etc., use Never-Seize

®

White

Food Grade with PTFE.

• Refer to separate valve manual for addition information.

Valve in need of

more clearance for

operation

• Multi-gasket design allows additional gaskets fro more clearance

and free operation.

Note: Adding too many gaskets to the valve eventually causes leakage.

WATER IN PUMP

GEARBOX

Leak coming from

above the pump

• Check all piping connections and tank overflow for possible spill-

age falling directly onto the pump gearbox.

• Repair accordingly.

Leaking mechanical

seal

• Inspect the oil seal and replace as needed. If the oil seal checks

OK, then the mechanical seal may need to be replaced.

• If a mechanical seal is installed there must be no leaks. See Sec-

tion 6 Repair, heading “Mechanical Seal Assembly” on page 74.

ROTATION

SYMPTOMS

(Reduced pressure

60-100 PSI [4.1-

6.9BAR] and

reduced flow.)

Wrong impeller

installed

• Verify the new impeller vanes are oriented the same as the old

impeller before installing. (See Figure 2-6: “Pump/Engine Rota-

tion,” on page 3-19.)

• Refer to relief / sensing valve manual and follow maintenance

instructions for disassembly, cleaning and lubrication.

Impellers installed

backwards (two-

stage pump)

• Verify the impellers are in the correct order - p/n: 016-0280-00-0 is

installed closest to the gearbox in an “Engine Rotation” applica-

tion and CLosest to the front in a “Opposite Engine Rotation”

application.

Wrong application

attempted

• The pump was installed on an application for which it was not

intended, i.e., front mount vs. rear mount.

NOTICE !

IT IS POSSIBLE TO REASSEMBLE THE PUMP INCORRECTLY OR WITH

THE WRONG PARTS. ALWAYS COMPARE THE REPLACEMENT PARTS

WITH THE ORIGINAL HARDWARE. CONTACT CUSTOMER SERVICE AT HALE

PRODUCTS TO ANSWER QUESTIONS OR CONCERNS.

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Charts