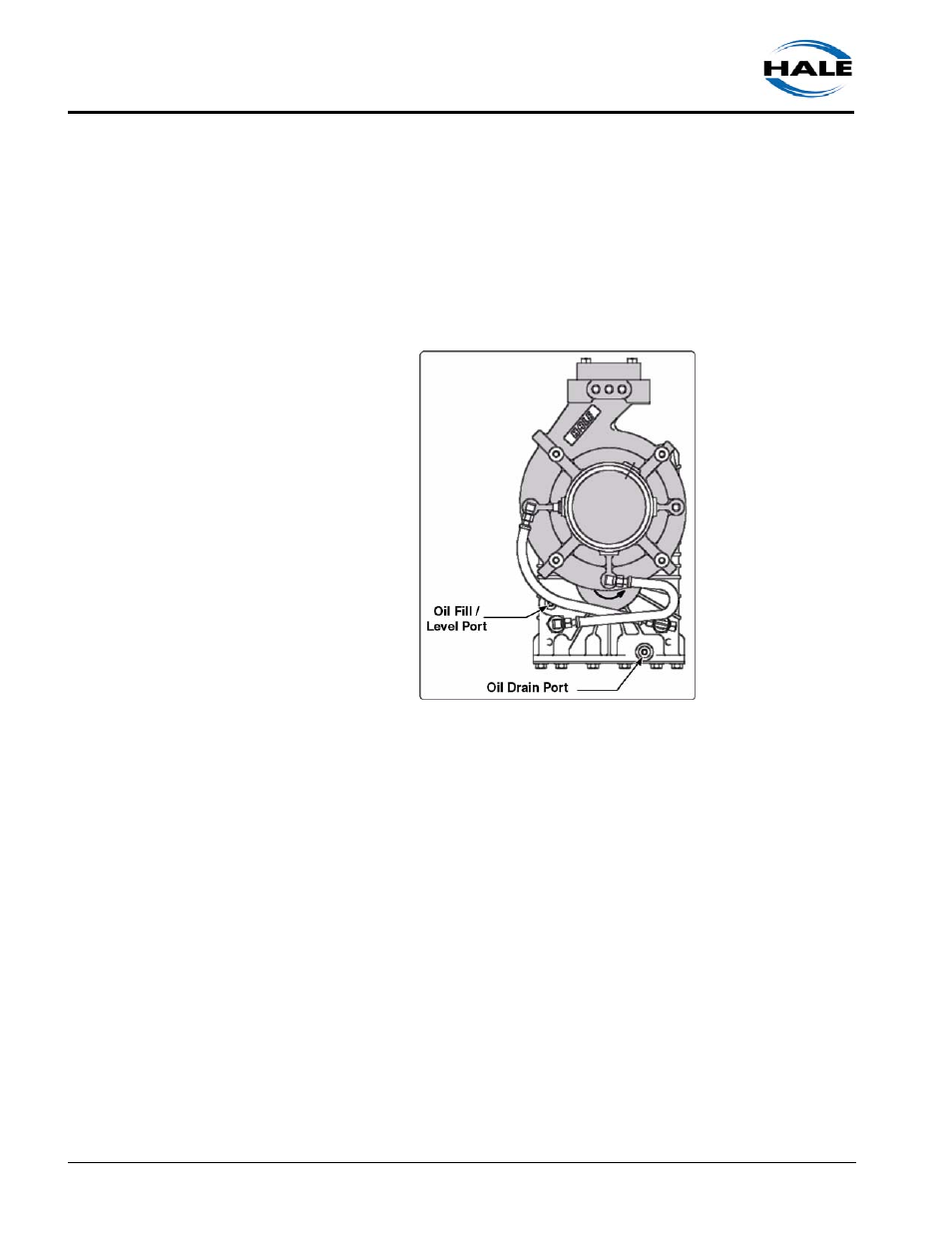

Figure 4-3: typical drain, fill and level plugs, Drive line and flange bolts, Priming system test (dry vacuum test) – Hale MBP Booster User Manual

Page 47

❑ Preventive Maintenance

46

Silencer Series Booster Pump, p/n: 029-0020-83-0

Incorrect oil types or amounts of oil result in unnecessary loss of power and

high oil temperature. Change the oil every 12 months, depending on pump

usage. All lubricants must meet service rating API GL-5 requirements.

(See Figure 4-2: “Gearbox Capacity / Recommended Lubricants,” on page

45.)

Note: Hale recommends using an SAE EP-90, 80W90 Lubricant or

“RoadRanger” Full Synthetic SAE 50 Transmission Lubricant, manufactured by

the Eaton

®

Corporation, or equivalent.

1. Remove the gearbox oil fill plug, and

check the level of the oil in the gearbox.

(See Figure 4-3: “Typical Drain, Fill and

Level Plugs.”)

2. The oil level should be up to the bottom

of the plug hole.

3. If the oil appears white or “milky,” a

water leak is indicated. Remove the

drain plug and drain the oil into a suit-

able container. Examine the oil for

metal flakes or other contamination.

4. Either of these conditions indicates

maintenance is required on the unit.

Drive Line and Flange Bolts

Check all drive line and flange bolts to ensure:

1. No bolts are missing.

2. All bolts are tight. Use a torque wrench to torque bolts to the drive train

manufacturer's recommended specifications.

Priming System Test (Dry Vacuum Test)

(Refer to NFPA 1901 or NFPA 1911)

1. Close all valves and drains. Cap all suction openings and the outlet of the

suction side relief valve (if equipped).

Figure 4-3: Typical Drain, Fill and

Level Plugs