Cavitation – Hale MBP Booster User Manual

Page 59

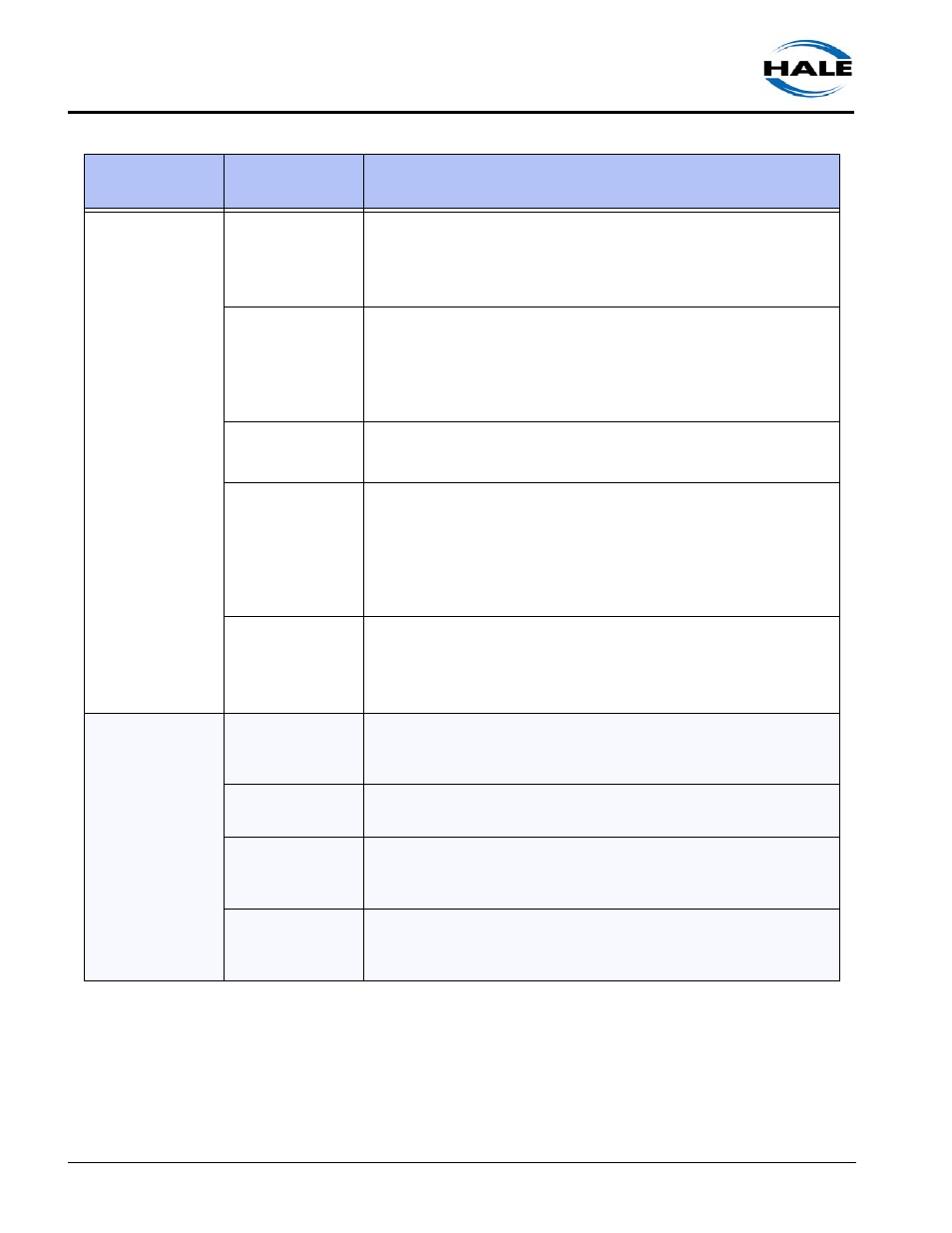

❑ Troubleshooting

58

Silencer Series Booster Pump, p/n: 029-0020-83-0

ENGINE SPEEDS

TOO HIGH FOR

REQUIRED

CAPACITY OR

PRESSURE -

continued

Faulty suction hose

• Inner line of suction hose may collapse when drafting and is usu-

ally undetectable.

• Try a different suction hose on the same pump.

• Test for comparison against original hose.

Blockage at suction

hose entry

• Clean suction hose strainer of obstruction. See Section 4 Preven-

tive Maintenance, heading “Intake Strainers” on page 44.

• Follow recommended practices for laying suction hose.

• Keep off the bottom of the fluid supply by at least 2 feet (0.6

meters) below the surface of the fluid.

Worn pump impel-

ler(s) or clearance

rings

• Repair and/or replace as needed. See Section 6 Repair, heading

“Servicing the Booster Pump” on page 69.

Impeller blockage

• A blocked impeller can prevent loss of both capacity and

pressure.

• Back flushing the pump from discharge to suction may free the

blockage.

• Removing half the pump body may be necessary - this is consid-

ered a major repair.

Pump is approach-

ing “Cavitation”

• Gate the discharge valves to allow pressure to increase. This

reduces the flow.

• Reduce the throttle opening to the original pressure setting.

• Also see heading “Cavitation” on page 36.

CAVITATION

(Pump beginning

to cavitate.)

Note: Also see

heading “Cavita-

tion” on page 36.

Chart continued on

next page.

Discharging more

water than the pump

is taking in

• Increase the flow into the pump with more and/or larger intake

lines.

• Gate the discharge valves to reduce flow and maintain pressure.

Air leak

• Verify that the air bleeder on the suction tube is NOT open.

• Locate and eliminate all air leaks during maintenance.

Drafting too high

• Verify lift hose, hose friction, water temperature and other lift limit-

ing factors are reduced or eliminated.

• Locate the pump closer to the water source.

Water temperature

too high

• Reduce volume discharge by lowering the RPM or gating the dis-

charge valves.

• Locate a source of cooler water.

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Charts