Hale MBP Booster User Manual

Page 57

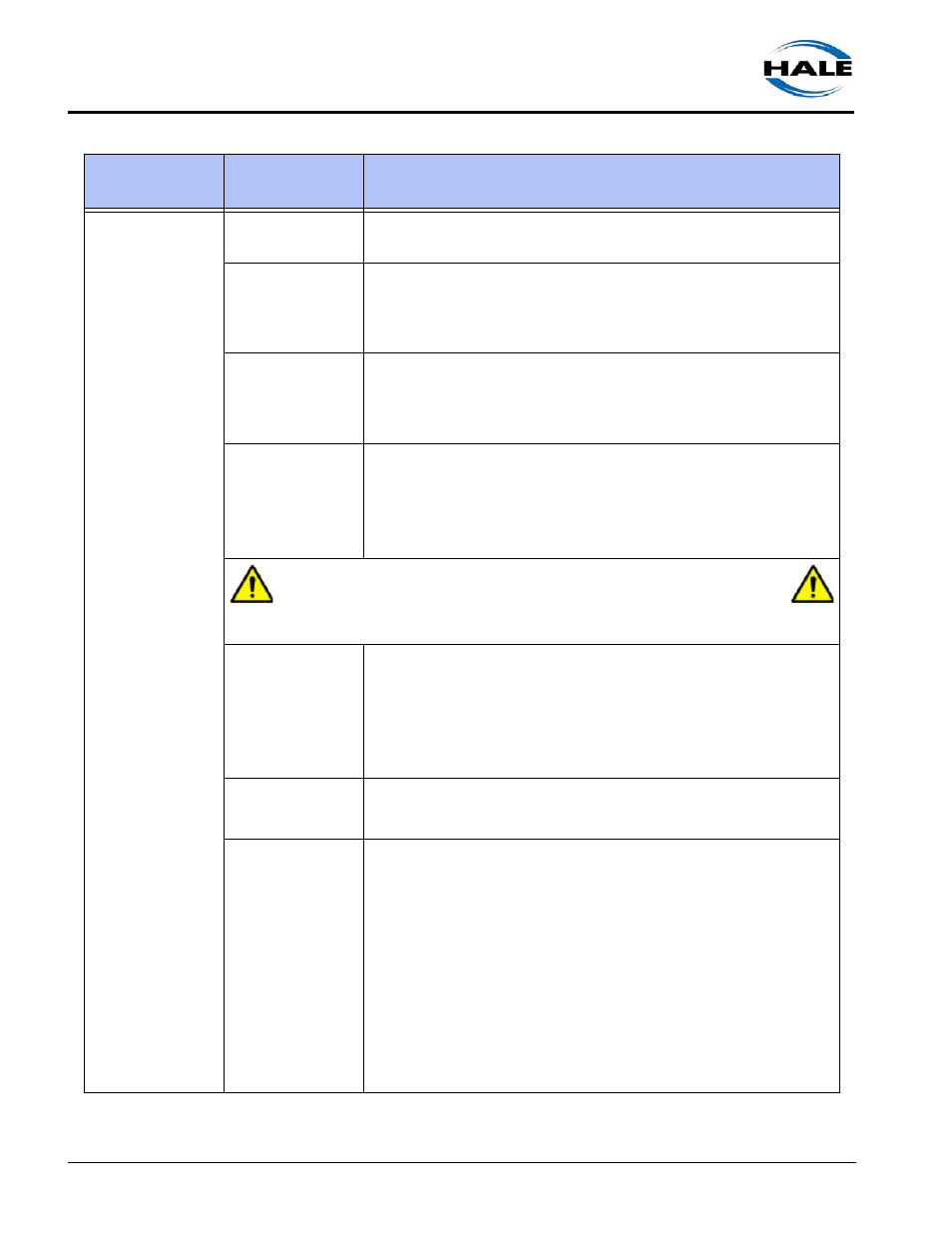

❑ Troubleshooting

56

Silencer Series Booster Pump, p/n: 029-0020-83-0

PUMP LOSES

PRIME OR WILL

NOT PRIME -

continued

Chart continued on

next page.

Blocked suction

strainer

• Remove obstruction from suction hose strainer.

• Thoroughly clean strainer screen.

Suction connections

• Avoid placing any part of the suction hose higher than the suction

intake.

• Suction hose should be laid out with continuos decline to fluid

supply.

Air trapped in suc-

tion line

• Avoid placing any part of suction hose higher than the suction

intake.

• Suction hose should be laid with continuous decline to fluid

supply.

Insufficient priming

• Proper priming procedures should be followed.

• Do not release the primer control before assuring a complete

prime.

• Open the discharge valve slowly during completion of prime to

ensure complete prime.

NOTICE !

DO NOT RUNTHE PRIMER OVER FORTH-FIVE (45) SECONDS. IF PRIME IS

NOT ACHIEVED WITHIN 45 SECONDS, STOP AND LOOK FOR CAUSES

(AIR LEAKS OR BLOCKED SUCTION HOSES.)

Air trapped in suc-

tion line.

• Avoid placing any part of suction hose higher than the suction

intake.

• Suction hose should be laid with continuous decline to fluid

supply.

• If air trapped in hose is unavoidable, repeated priming may be

necessary to eliminate air pockets in suction hoses.

Pump pressure too

low when nozzle is

opened.

• Prime pump again and maintain higher pump pressure while

opening the discharge valve slowly.

Air leaks

• Attempt to located and correct air leaks using the following

• procedures:

•

• Perform “Dry Vacuum Test” on pump per NFPA standards with 22”

minimum vacuum required with loss not to exceed 10” of vacuum

in five (5) minutes.

• If a minimum of 22” of vacuum cannot be achieved, the priming

device or system may be defective, or the leak is too big for the

primer to overcome (such as an open valve).

• After priming shut off the engine. Audible detection of a leak is

often possible.

Condition

Possible

Cause

Suggested Corrective Action

Figure 5-2: Troubleshooting Charts