Trv-l kit, Anodes, Figure 2-12: hale anode – Hale MBP Booster User Manual

Page 26

25

Silencer Series Booster Pump, p/n: 029-0020-83-0

Introduction

❑

After the temperature returns to a safe level, the valve closes.

TRV-L Kit

(See Figure 2-11: “Thermal Relief Valve, TRV,” on page 24.)

The TRV-L kit includes a chrome panel placard with a warning lamp, a lamp

test button, and a pre-assembled wire harness. The light illuminates when

the TRV is open and discharging water.

An optional buzzer provides audible warning. The buzzer mounts on the

operator panel.

Anodes

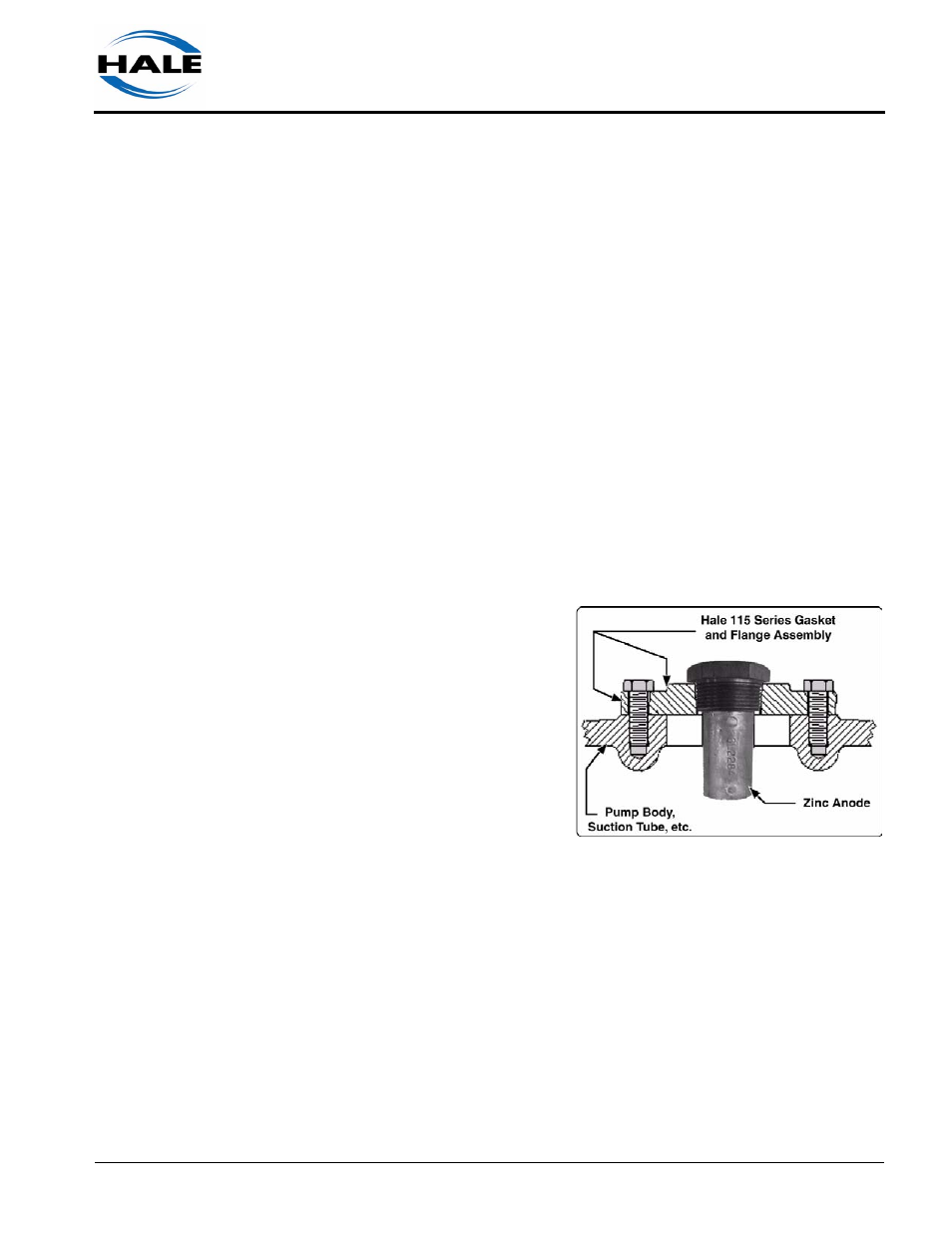

(See Figure 2-12: “Hale Anode.”)

The Hale Anode System helps prevent damage caused by galvanic corro-

sion in the pump. Galvanic action pits the pump and pump shaft material

through the electrolysis of water in the pump. The popularity of noncorro-

sive water tanks and piping has increased this type of corrosion in today’s

fire pumps.

The Hale Anode System is a sac-

rificial metal, which helps to

diminish or prevent corrosion.

The anode fits on any Hale truck

mounted pump, regardless of

age or model.

The Anode kit is designed for

installation in the standard Hale

115 series flange opening. On

fabricated manifolds and similar

applications, the installer is to

provide 1-1/4” NPT openings and

install anodes directly. It is rec-

ommended that one anode be

installed on each suction manifold and one on the discharge side. Typically,

three are used. Anodes can be mounted in any position, horizontal or

vertical.

Zinc anodes should be inspected every twelve (12) months. Replace when

over 75% of the zinc has been consumed. Performance of the anode varies

with water quality and PH. Anodes conform to Mil Spec. A18001.

Figure 2-12: Hale Anode