Worn clearance rings and impeller hubs, Anode check, Figure 4-8: hale anode – Hale MBP Booster User Manual

Page 55

❑ Preventive Maintenance

54

Silencer Series Booster Pump, p/n: 029-0020-83-0

Worn Clearance Rings and Impeller Hubs

Before assuming that clearance ring wear is at fault or that clearance ring

replacement requires pump disassembly, it is advisable to thoroughly check

other possible causes of low performance.

Clearance rings limit the internal bypass of water from the discharge side of

the pump back to suction. The radial clearance between the impeller hub

and the clearance rings is only a few thousandths of an inch when new. In

clear water, the clearance rings continue to effectively seal for many hours

of operation.

In dirty or sandy water, the impeller hub and clearance rings wear faster.

The more wear, the greater the bypass and lower pump performance.

It should not be necessary to replace clearance rings until a loss in pump

performance is noticed during the annual test – see “Performance Testing

Overview” on page 50. For clearance ring and impeller service, proceed to

Section 6, heading “Impeller” on page 71.

Often, replacement of the clearance rings reduces the bypass and restores

the pump to near original performance. A complete restoration requires that

the impellers also be replaced. See Section 6 “Repair” on page 61 for

maintenance and repair information if pump disassembly is required.

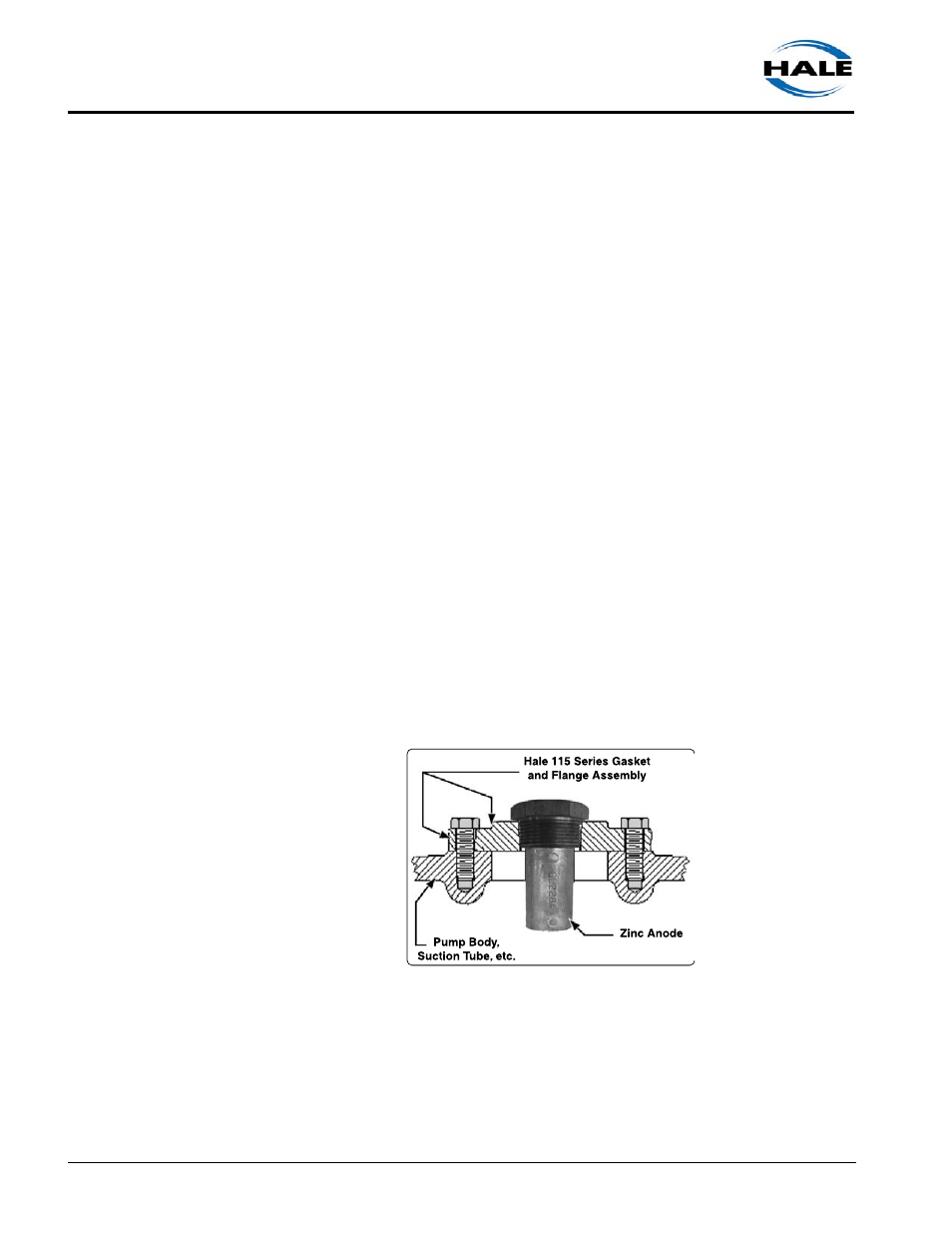

Anode Check

The zinc anodes should be

inspected every 12 months.

Replace when over 75% of the zinc

has been consumed. Performance

of the anode life varies with water

quality and pH. Anodes conform to

MIL Spec. A180001.

Figure 4-8: Hale Anode