Electrical section – Brother BES-962BC User Manual

Page 256

BES-962BC • BES-1262BC

254

Chapter 12 Troubleshooting

An overtravel error occurs.

• Is the frame within the cap frame area?

Move the frame within the cap frame area and turn on the power.

• Check to see if the signal of the X area sensor turns ON and OFF in

PORT test mode.

When the signal does not change, refer to the block diagram showing

the cable connections and check to see if connection from the X area sensor

to the main PCB is proper. Replace the X area sensor with a new one.

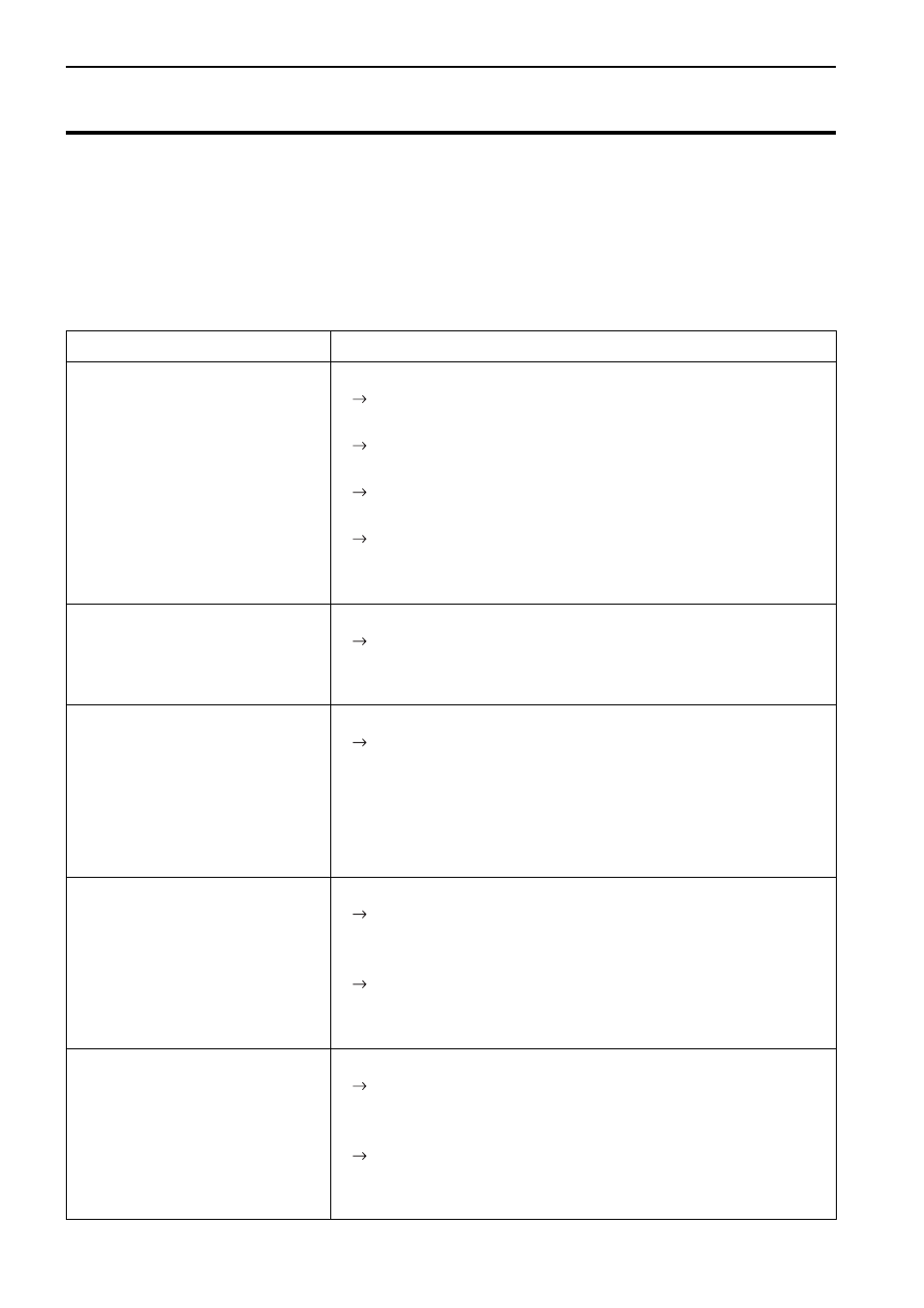

Electrical Section

Cautions

• Be sure to turn off the power of the machine and unplug the power cord before checking cable

connections.

• When you check connection of the cables as instructed in this manual, also check connection and

continuity between connectors.

• Carry out items described in the "Measures" section in order of appearance.

• Some checks and replacement works can be conducted only by repair people. In such cases,

contact your dealer.

Symptom

Measures

The machine does not operate even

if the power is turned on.

• Is the power cord of the machine plugged in?

Plug in the power cord.

• Is the connector at the rear of the control box connected?

Connect it after checking the connector number and the harness number.

• Is the connector in the control box or the power supply base connected?

Connect it after checking the types and colors of the connectors.

• Is fuse F1 or F2 on the power PCB in the power supply base blown?

Replace the fuse with a new one. If the fuse is blown again,

something is faulty. Check to see if the wiring is correct. Replace the

control box with a new one.

The machine does not operate even

if the power is turned on.

The message, "Release stop SW to

operate!", is displayed on the panel.

• Is the stop switch turned on?

Reset the stop switch.

• The message, "Is the presser foot

removed?", is displayed on the

machine controller when the power

is turned on.

• The red LED of head 2 or 4 or 6

does not light and the presser foot

remains lowered.

• Is the retract bed sensor adjusted properly?

Adjust the retract bed sensor of the faulty head. (Refer to "Replacing

the retract bed sensor PCB".)

• Refer to the block diagram showing cable connection and check

connection from the retreat bed sensor to the main PCB.

• Check to see if the frame type is set to every other head with the

machine controller.

The needle stop position error oc-

curs.

• Is the pulley manually turned and out of the stop angle?

Turn the pulley, adjust the needle at the stop position, and reset

the error.

• Check the signal of the stop position sensor in the encoder test mode.

Refer to the adjustment or cable connection block diagram and

check connection from the needle position detention sensor to the main

PCB. Replace the needle position detection sensor with a new one.