Troubleshooting – Red Lion DLC User Manual

Page 27

27

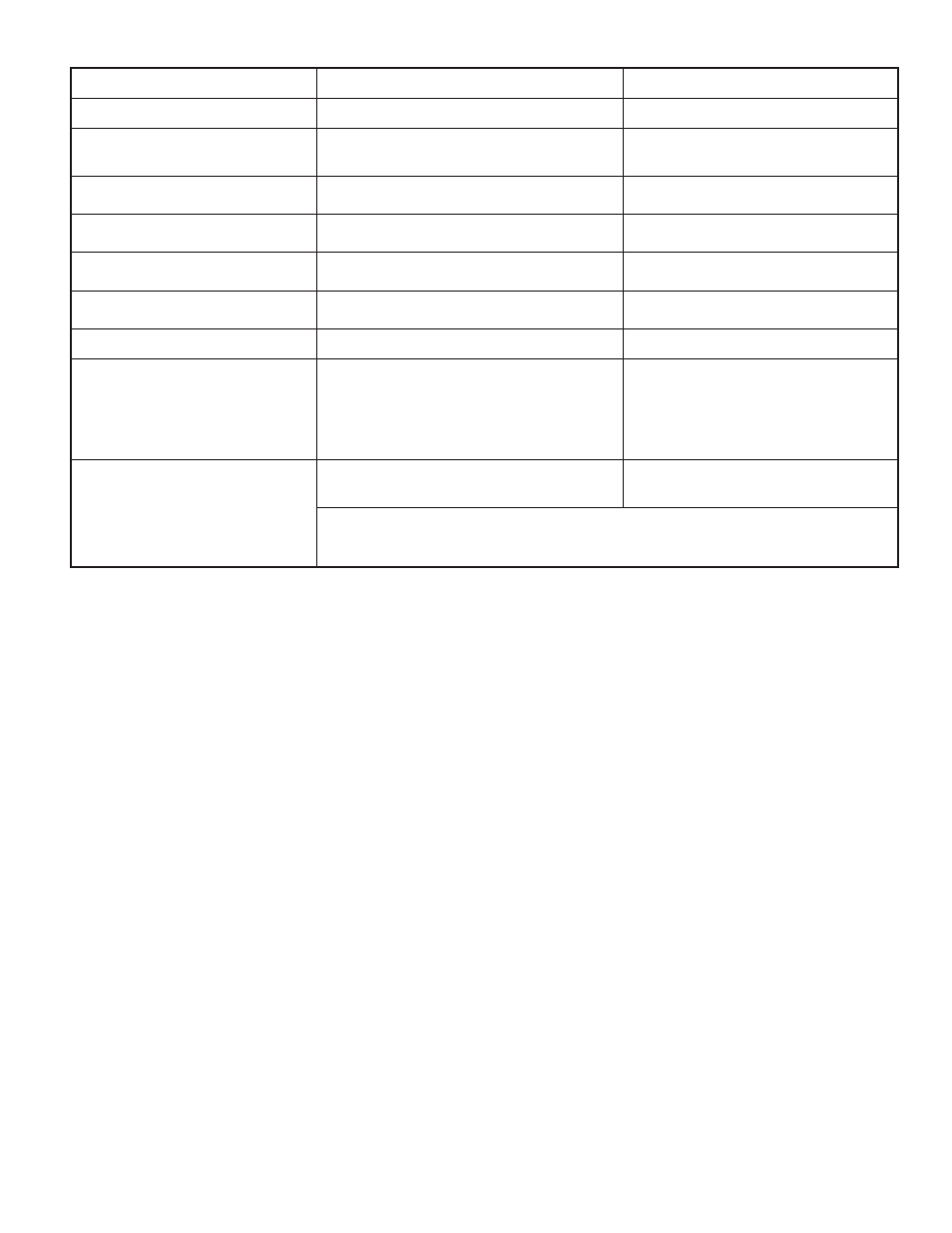

TROUBLESHOOTING

PROBLEM

CAUSE

REMEDIES

Power LED will not light

Controller power

Check controller power connections and voltage level

Process Value not changing or incorrect

Check input signal connections and signal level

Check proper channel setup, reading and connections

Check input setup, scaling values, and re-download

Alarms not functioning properly

Adjust alarm value, alarm hysteresis, and setpoint

value to ensure valid trigger points

Process Value stays at -32001 or +32001

Input Signal (sensor) under-range or over-range *

Check input type, level, channel, jumpers and

re-download. Replace sensor. Perform calibration.

Process Value stays at -32002

Shorted RTD sensor *

Check input sensor, level, channel, jumpers and

re-download. Replace probe.

Process Value stays at +32002

Open TC or RTD sensor *

Check input sensor, level, channel, jumpers and

re-download. Replace probe.

Process Value stays at -32003 or +32003

Check input level, scaling, jumpers and re-download

Process Value stays at +32100, All LEDs

Flashing, Alarms disabled

Will not communicate (Comm. LED not flashing)

Verify DLC communications setup

Go to pull down menu SETTINGS,PC PORT SETTING

Try switching A+ and B- lines

Input signal

Incorrect channel

Incorrect programming

Calculated trigger points are over +32000 or below -32000

Process Value underrange (<-32000) or overrange (>+32000)

Incorrect serial settings (DLC port)

Incorrect serial settings (computer port)

Incorrect wiring

Note: The DLC serial settings must match the device that it is communicating with. If you do not know or cannot recall

the DLC settings, they can be reset back to factory defaults. Simply jumper the Default Serial terminal to Input

Common or by putting the Default Serial setting DIP switch in the “UP” position.

* Can also be monitored by accessing coils 5-8 and 17-20, or register 40504.

†

Can also be monitored by accessing coils 1-3, 29-30 or register 40505.

For further technical assistance, contact technical support.

Re-download SFDLC file

Perform calibration procedure

Consult Factory

Check A & B Setpoint Ramp Rate and Hold Time

Segments. Change minimum of 1 segment register for

each channel to cause a new checksum to be written

Consult Factory

Parameter checksum error †

Calibration checksum error †

Integral and Offset/Manual Power checksum error †

Setpoint Controller Segment Memory checksum error †

Setpoint Controller Status Memory checksum error †