Pid tuning explanations, Auto-tune, Auto-tune code figure – Red Lion DLC User Manual

Page 19: Start auto-tune, Auto-tune progress, Pid adjustments, Process response extremes

19

AUTO-TUNE

Auto-Tune is a user-initiated function where the controller automatically determines the

Proportional Band, Integral Time, Derivative Time, Digital Filter, Control Ouput Dampening

Time, and Relative Gain (Heat/Cool) values based upon the process characteristics. The

Auto-Tune operation cycles the controlling output(s) at a control point three-quarters of the

distance between the present process value and the setpoint. The nature of these oscillations

determines the settings for the controller’s parameters.

Prior to initiating Auto-Tune, it is important that the controller and system be first tested.

(This can be accomplished in On/Off Control or Manual Control Mode.) If there is a wiring,

system or controller problem, Auto-Tune may give incorrect tuning or may never finish.

Auto-Tune may be initiated at start-up, from setpoint or at any other process point. However,

insure normal process conditions (example: minimize unusual external load disturbances) as

they will have an effect on the PID calculations. Auto-Tune cannot be initiated while running

a profile.

TIME

INPUT

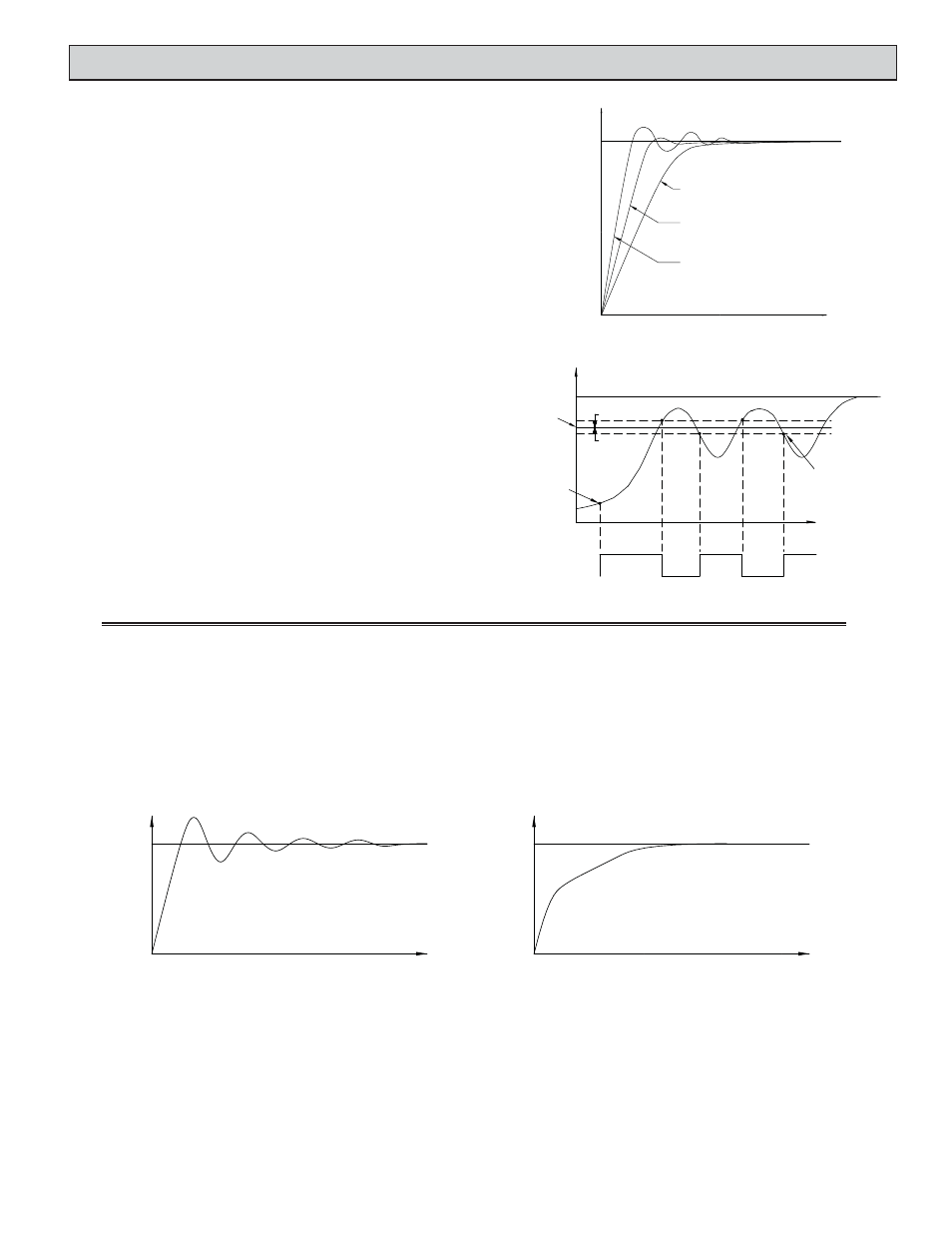

TYPICAL RESPONSE CURVES WITH

AUTO-TUNE CODES 0 TO 2.

SP

0

1

2

AUTO-TUNE CODE FIGURE

PID TUNING EXPLANATIONS

Start Auto-Tune

1. Enter the On/Off Control Hysteresis value.

(For most applications, 10 is a suggested value.)

2. Enter the Deadband value, if using OP2.

(For most applications, 0 is a suggested value.)

3. Enter the Setpoint value.

(If Auto-Tune overshoot is unacceptable, then lower the value and restart.)

4. Enter the Auto-Tune Code. (See Figure for details)

5. Enter ‘1’ in the Auto-Tune Start register . (Channel A 40011/Channel B 40027).

6. The Auto-Tune LED will come on.

Auto-Tune Progress

The controller will oscillate the controlling output(s) for four cycles. The cycling

phase can be monitored from the Auto-Tune Phase Register (Channel A 40012/

Channel B 40028). The time to complete the Auto-Tune cycles is process dependent.

The controller should automatically stop Auto-Tune and store the calculated values

when the four cycles are complete. If the controller remains in Auto-Tune unusually

long, there may be a process problem. Auto-Tune may be stopped by entering ‘0’ in

Auto-Tune Start Register (Channel A 40011/Channel B 40027).

TIME

INPUT

1

4

AUTO-TUNE

START

AUTO-TUNE

CONTROL

POINT

SETPOINT

AUTO-TUNE COMPLETE, PID

SETTINGS ARE CALCULATED

AND LOADED INTO MEMORY

2

3

ON

OFF

ON

OFF

Output 1 (OP1) :

PHASE

½ HYS *

AUTO-TUNE OPERATION

(REVERSE ACTING)

½ HYS *

* - On/Off Control Hysteresis

TIME

SP

SP

TIME

INPUT

INPUT

OVERSHOOT AND OSCILLATIONS

SLOW RESPONSE

TO DAMPEN RESPONSE:

- USE SETPOINT RAMPING.

- USE OUTPUT POWER LIMITS.

- RE-INVOKE AUTO-TUNE WITH A

HIGHER AUTO-TUNE CODE.

- INCREASE PROPORTIONAL BAND.

- INCREASE INTEGRAL TIME.

- INCREASE DERIVATIVE TIME.

TO QUICKEN RESPONSE:

- INCREASE OR DEFEAT SETPOINT RAMPING.

- EXTEND OUTPUT POWER LIMITS.

- RE-INVOKE AUTO-TUNE WITH A

LOWER AUTO-TUNE CODE.

- DECREASE PROPORTIONAL BAND.

- DECREASE INTEGRAL TIME.

- DECREASE DERIVATIVE TIME.

- CHECK CYCLE TIME.

PID Adjustments

In some applications, it may be necessary to fine tune the Auto-Tune

calculated PID parameters. To do this, a chart recorder or data logging device is

needed to provide a visual means of analyzing the process. Compare the actual

process response to the PID response figures with a step change to the process.

Make changes to the PID parameters in no more than 20% increments from the

starting value and allow the process sufficient time to stabilize before evaluating

the effects of the new parameter settings.

In some unusual cases, the Auto-Tune function may not yield acceptable

control results or induced oscillations may cause system problems. In these

applications, Manual Tuning is an alternative.

PROCESS RESPONSE EXTREMES