Step 12 programming the outputs – Red Lion DLC User Manual

Page 11

11

Pause: Pause signifies that a profile is active but the time base (Profile Phase Timer) is paused. The pause mode can only be invoked by writing a

3 in the Profile Operating Status register. Pausing a profile during a ramp phase pauses the ramp and the controller maintains control at the

ramping setpoint value (40045/40053) at the instant of the pause action. The use of pause, effectively lengthens the total run time of a profile.

The unit will remain in pause mode until it is placed back in the run mode by writing a 2 (Run/Start) into the Profile Operating Status Register.

Error Delay (Guaranteed Soak): The Error Delay Setting is used only as a status indication. It indicates that a profile is active but the phase timer

or profile advancement has stopped. This is caused by automatic action of the controller when the process deviates more than a specified amount

from the active profile segment. The Error Delay is similar to pause, except the error delay status can only be invoked automatically. See "Profile

Error Band Mode (40322/40422)." Do not write a "4 - Error Delay," to the Profile Operating Status Register. Doing so will instead put the

controller in pause mode (3).

Profile Phase (40066/40074): When the profile is active, this register indicates whether the controller is in a ramp (0) or hold (1) phase.

Profile Segment (40067/40075): Indicates the current active segment while the profile is running. A zero indicates that the profile is stopped or off.

Profile Phase Timer (40068/40076): This register shows the remaining segment phase time in 10ths of minutes. The remaining phase time can be

changed "on the fly" to accelerate or decelerate the phase time. The change in phase time will only affect the running profile and not the stored

parameters. If the phase time is changed during the ramp phase, a new ramp rate will be calculated which will achieve the desired phase time. The

Profile Phase Timer will stop while the unit is paused or during an error delay caused by Profile Error Band operation (guaranteed soak).

Profile Cycle Count Remaining (40069/40077): Indicates the number of profile cycles that are yet to be run. If the Profile Cycle Count register

(40326/40426) is set to 250, the Profile Cycle Count Remaining Register will run continuously, resetting to "250" when reaching "0". This register

value can be changed, however, it will only affect the current run cycle. When the profile is stopped and re-started, the Profile Cycle Count

Remaining Register will be reloaded based on the "Profile Cycle Count (40326/40426)" value.

Advance Profile Phase (40070/40078): Writing a "1" to this register while the profile is running will cause the controller to advance immediately to

the beginning of the next ramp or hold phase. Using the advance operation shortens the total run time of the profile. If the profile is "paused," the

profile will advance but the profile will remain paused. The Profile can also be advanced while in the error delay mode.

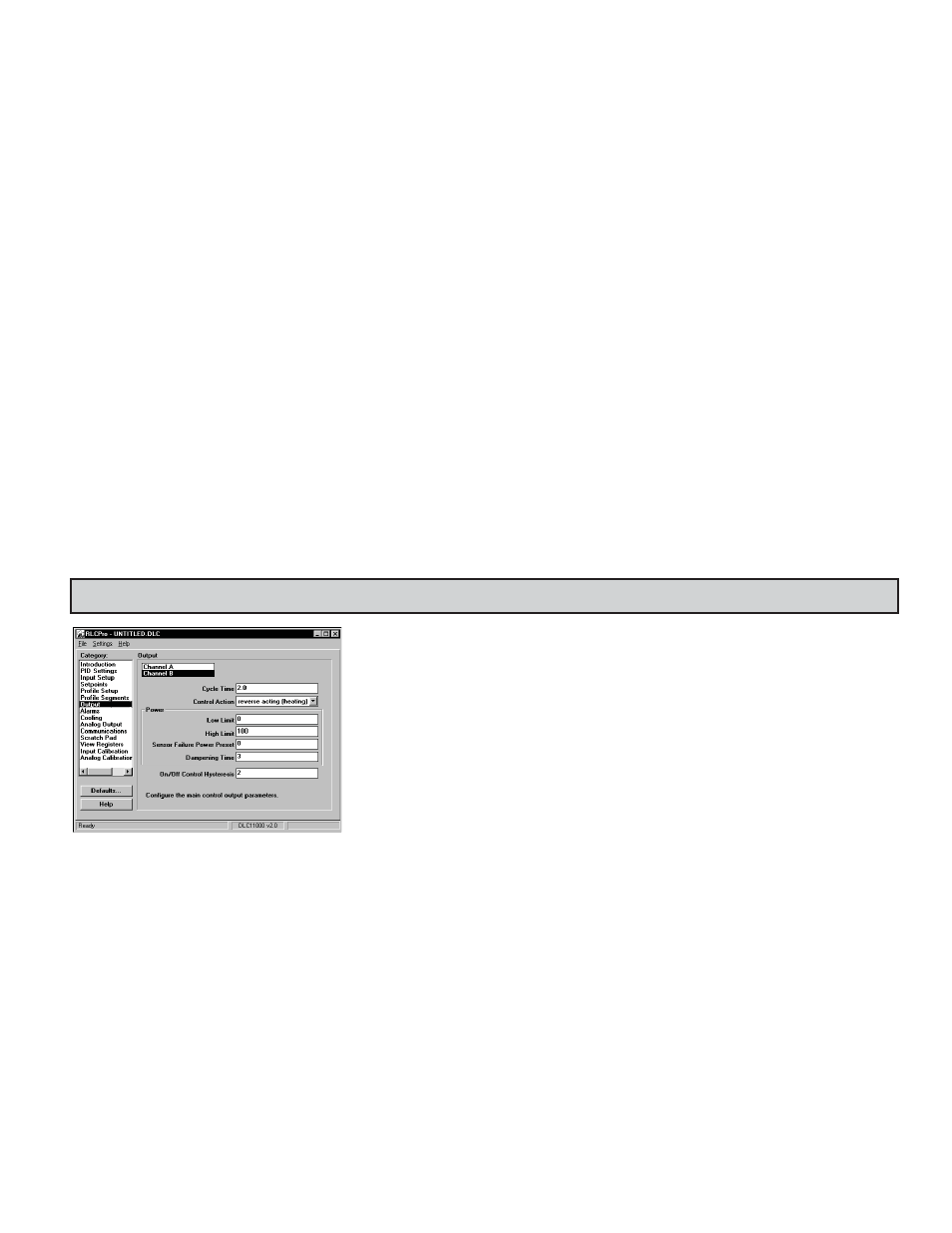

STEP 12 PROGRAMMING THE OUTPUTS

Cycle Time (40116/40216): The cycle time, entered in seconds, is the combined time of an on and off

cycle of a time proportioning control output OP1/OP2. With time proportional output, the percentage

of control power is converted into output on time of the cycle time value. (If the controller calculates

that 65% power is required and has a cycle time of 10 seconds, the output will be on for 6.5 seconds

and off for 3.5 seconds.) For best control, a cycle time equal to one-tenth of the process time constant,

or less, is recommended. When using the DC Analog output signal for control, a setting of zero will

keep output OP1 off. The status of OP1 can be read through registers 40014/40030.

Control Action (40117/40217): This determines the control action for the PID loop. Programmed for

direct action (cooling), the DLC output power will increase if the Process value is above the Setpoint

value. Programmed for reverse action (heating), the output power decreases when the Process Value is

above the Setpoint Value. For heat and cool applications, this is typically set to reverse. This allows

OP1 to be used for heating, and AL2/OP2 to be used for cooling.

Power Low Limit (40118/40218); High Limit (40119/40219): These parameters may be used to limit controller power due to process disturbances

or setpoint changes. Enter the safe output power limits for the process. If Alarm 2 is selected for cooling, the range is from -100 to +100%. At 0%,

both OP1 and OP2 are off; at 100%, OP1 is on; and at -100%, OP2 is on. When the controller is in Manual Control Mode, these limits do not apply.

Sensor Fail Power Preset (40120/40220): This parameter sets the power level for the control outputs in the event of a sensor failure or extreme

overdriven/underdriven input. If Alarm 2 is not selected for cooling, the range is from 0% (OP1 output full off) to 100% (OP1 output full on). If

AL2 is selected for cooling, the range is from -100 to +100%. At 0%, both OP1 and OP2 are off; at 100%, OP1 is on; and at -100%, OP2 is on. The

alarm outputs are upscale drive with an open sensor, and downscale drive with a shorted sensor (RTD only), independent of this setting. Manual

Control overrides the sensor fail preset.

Dampening Time (40121/40221): The dampening time, entered as a time constant in seconds, dampens (filters) the calculated output power.

Increasing the value increases the dampening effect. Generally, dampening times in the range of one-twentieth to one-fiftieth of the controller’s

integral time (or process time constant) is effective. Dampening times longer than these may cause controller instability due to the added lag effect.

On/Off Control Hysteresis (40122/40222): The controller can be placed in the On/Off Control Mode by setting the Proportional Band to 0.0%. The

On/Off Control Hysteresis (balanced around the setpoint) eliminates output chatter. In heat/cool applications, the control hysteresis value affects

both Output OP1 and Output OP2 control. It is suggested to set the hysteresis band to 2 (Factory Setting) prior to starting Auto-Tune. After Auto-

Tune, the hysteresis band has no effect on PID Control. On/Off Control Hysteresis is illustrated in the the On/Off Control Mode section.