On/off control, Pid control, Remote setpoint – Red Lion DLC User Manual

Page 18: On/off control - reverse or direct acting figures, On/off control - heat/cool output figures, Typical pid response curve

18

ON/OFF CONTROL

The controller operates in On/Off Control when the Proportional Band is set

to 0.0%. In this control, the process will constantly oscillate around the setpoint

value. The On/Off Control Hysteresis (balanced around the setpoint) can be

used to eliminate output chatter. Output OP1 Control Action can be set to

reverse for heating (output on when below the setpoint) or direct for cooling

(output on when above the setpoint) applications.

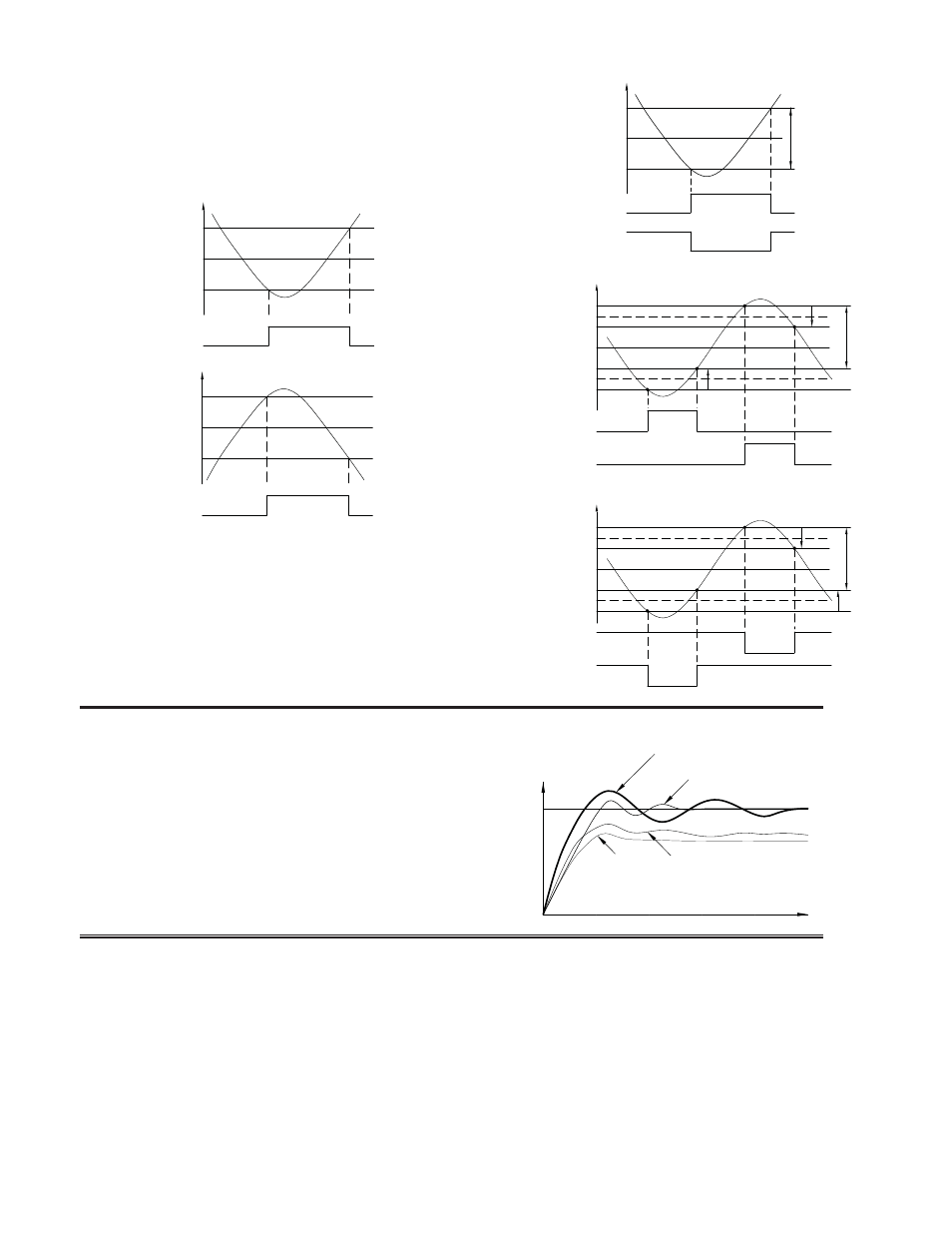

ON/OFF CONTROL - REVERSE OR DIRECT ACTING FIGURES

For heat and cool systems, OP1 Control Action is set to reverse (heat) and the

Alarm 2 Action is set to cooling (OP2). The Proportional Band is set to 0.0 and

the Relative Gain in Cooling to 0.0. The Deadband in Cooling sets the amount

of operational deadband or overlap between the outputs. The setpoint and the

On/Off Control Hysteresis applies to both OP1 and OP2 outputs. The hysteresis

is balanced in relationship to the setpoint and deadband value.

ON/OFF CONTROL - HEAT/COOL OUTPUT FIGURES

OFF

Output 1 (OP1) :

OFF

SP

ON

INPUT

REVERSE ACTING

SP+1/2 HYS

SP-1/2 HYS

OFF

Output 1 (OP1) :

SP

OFF

INPUT

DIRECT ACTING

SP-1/2 HYS

SP+1/2 HYS

ON

ON

Output 2 (OP2) :

ON

SP

OFF

INPUT

HEAT/COOL DEADBAND VALUE (db) = 0

SP + 1/2 HYS

SP - 1/2 HYS

OFF

OFF

Output 1 (OP1) :

ON

HYS

SP

SP + 1/2 (db) - 1/2 HYS

SP + 1/2 (db) + 1/2 HYS

SP - 1/2 (db) + 1/2 HYS

SP - 1/2 (db) - 1/2 HYS

HEAT/COOL DEADBAND VALUE (db) < 0

db

HYS

HYS

ON

OFF

OFF

ON

Output 1 (OP1) :

Output 2 (OP2) :

ON

ON

INPUT

SP + 1/2 (db)

SP - 1/2 (db)

db

Output 1 (OP1) :

Output 2 (OP2) :

SP - 1/2 (db) + 1/2 HYS

SP - 1/2 (db) - 1/2 HYS

OFF

SP

ON

OFF

OFF

ON

HYS

OFF

HEAT/COOL DEADBAND VALUE (db) > 0

SP + 1/2 (db) - 1/2 HYS

SP + 1/2 (db) + 1/2 HYS

HYS

INPUT

SP + 1/2 (db)

SP - 1/2 (db)

PID CONTROL

In PID Control, the controller processes the input and then calculates a

control output power value by use of a modified Proportional Band, Integral

Time, and Derivative Time control algorithm. The system is controlled with the

new output power value to keep the process at the setpoint. The Control Action

for PID Control can be set to reverse for heating (output on when below the

setpoint) or direct for cooling (output on when above the setpoint) applications.

For heat and cool systems, the heat (OP1) and cool (OP2) outputs can be used

together in the PID Control. The PID parameters can be Auto-Tune or Manual

Tune to the process.

TYPICAL PID RESPONSE CURVE

SP

TIME

P & I

P & I & D

P only

P & D

INPUT

REMOTE SETPOINT

Channel B can operate as a Remote Setpoint Input to Channel A. Channel B

PID control is not functional when the input is assigned as a Remote Setpoint.

This mode of operation enables Cascade control (external), Ratio control, and

Temperature Setpoint Slave control, among others.

The Remote Setpoint value used internally by the controller is:

Remote Setpoint = (Scaled CHB Input * Remote Setpoint Ratio Multiplier)

+ Remote Setpoint Bias Offset

where Ratio Multiplier

= 0.0001 to 3.2000

Bias Offset

= -32000 to 32000

The Ratio Multiplier and Bias Offset parameters offer on-line scaling of the

Remote Setpoint to adjust control ratios or biases among related processes.

The Remote Setpoint is restricted to the setpoint low and high limit values for

channel B. These parameters may be used to limit the range of the Remote

Setpoint to a safe or more stable control range. For Remote Setpoint signal

sources that change wildly or are too sensitive to process upsets, the CHA

Setpoint Ramp Rate parameter (40110) can be used to ramp (rate limit) the

Remote Setpoint reading. This can subsequently reduce the fluctuations of the

secondary control loop.

Note: HYS in the On/Off Control Figures refers to the On/Off Control Hysteresis.