Control mode explanations, Application, Manual control mode – Red Lion DLC User Manual

Page 17: Mode transfer, Automatic control mode, Analog output calibration

17

ANALOG OUTPUT CALIBRATION

Calibration Type: This specifies the Analog Output point to be calibrated.

Volts: Analog Output Voltage calibration requires a precision meter with an accuracy of 0.05% (or better)

that is capable of measuring 10.00 V.

mA: Analog Output Current calibration requires a precision meter with an accuracy of 0.05% (or better)

that is capable of measuring 20.00 mA.

Meter Value: After pressing the Calibrate button, this shows the value the DLC is outputting. Measure the

actual output with an external meter and enter that value here. Press the Calibrate button again and follow

the prompts.

Calibrate: The Calibrate button initiates the calibration process after the appropriate settings are selected.

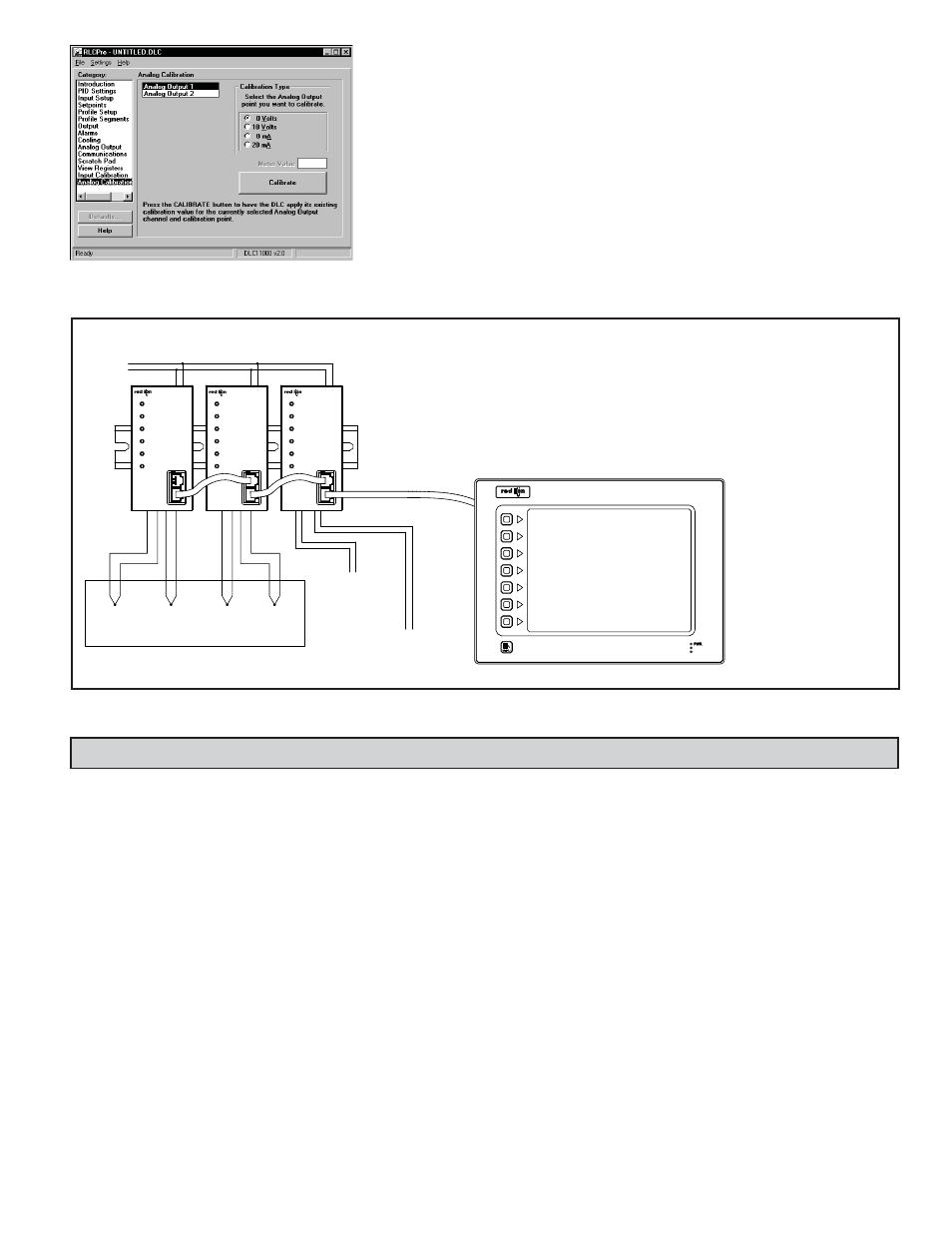

APPLICATION

A plastic extrusion company was building a four-zone extruder, and wanted a centrally located,

multi-zone interface. The interface needed to display the temperature and setpoint values, as well as

the screw RPM and barrel pressure. The customer provided a speed proportional 0-10 Volt signal

from a motor drive, and installed a 4-20 mA output pressure sensor in the extruder barrel. Each of

the four heat/cool zones were equipped with a thermocouple.

Three DLC-Dual Loop Controllers, with a G3 HMI, allowed the customer to build his own control

system. Only three DLCs were required; two were needed to control the four temperature zones, and

one was needed to monitor the two process signals.

All three units were

connected to the RS485

port of the G3 display. The

customer created his own

displays on the HMI,

which allowed him to

monitor and control the

setpoints and alarms

within the DLCs. The G3’s

multi-protocol capability

allowed it to tie the DLCs

to his PLC, creating a true

centralized interface.

CONTROL MODE EXPLANATIONS

MANUAL CONTROL MODE

In Manual Control Mode, the controller operates as an open loop system

(does not use the setpoint and process feedback). The user enters a percentage

of power through the Output Power register (40005/40021) to control the heat

(reverse) or cool (direct) for Output OP1. When Alarm 2 is configured for

Cooling (OP2), Manual operation provides 0 to 100% power to OP1 (heating)

and -100 to 0% power to OP2 (Cooling). The Low and High Power limits are

ignored when the controller is in Manual.

For time proportional outputs, the output power is converted into output On

time using the Cycle Time. For example, with a four second cycle time and 75%

power, the output will be on (4 × 0.75) for three seconds and off for one second.

For Analog Outputs (0-10 VDC or 0/4-20 mA), the percent output power is

converted into a linear value according to the Percent Low and High scaling set

for the analog output. For example, with 0 VDC (scaled 0.0%) to 10 VDC

(scaled 100%) and 75% power, the analog output will be 7.5 VDC.

MODE TRANSFER

When transferring the controller mode from or to Automatic, the controlling

outputs remain constant, exercising true bumpless transfer. When transferring

from Manual to Automatic, the power initially remains steady, but Integral

Action corrects (if necessary) the closed loop power demand at a rate

proportional to the Integral Time. The Control Mode can be changed through

the Control Mode register (40041/40049).

AUTOMATIC CONTROL MODE

In Automatic Control Mode, the percentage of output power is automatically

determined by PID or On/Off calculations based on the setpoint and process

feedback. For this reason, PID Control and On/Off Control always imply

Automatic Control Mode.

PROTOCOL

MODBUS

RS485

RS485

PROTOCOL

MODBUS

RS485

MODBUS

PROTOCOL

ZONE 4

ZONE 3

FOUR-ZONE EXTRUDER

POWER

18-36VDC/

24VAC

0-10V SIG.

4-20mA SIG.

(FROM PRESSURE

(FROM MOTOR DRIVE)

+

SENSOR)

HMI UNIT

+

+

ZONE 2

+

ZONE 1

MODEL DLC

RED LION CONTROLS

MODEL DLC

RED LION CONTROLS

MODEL DLC

RED LION CONTROLS