Liquid product control valve configuration options – Ag Leader InSight Direct Command Liquid User Manual

Page 9

Part No. 2002831-38 Rev. B

9

Section 7: Liquid Control Valve

Configuration Options

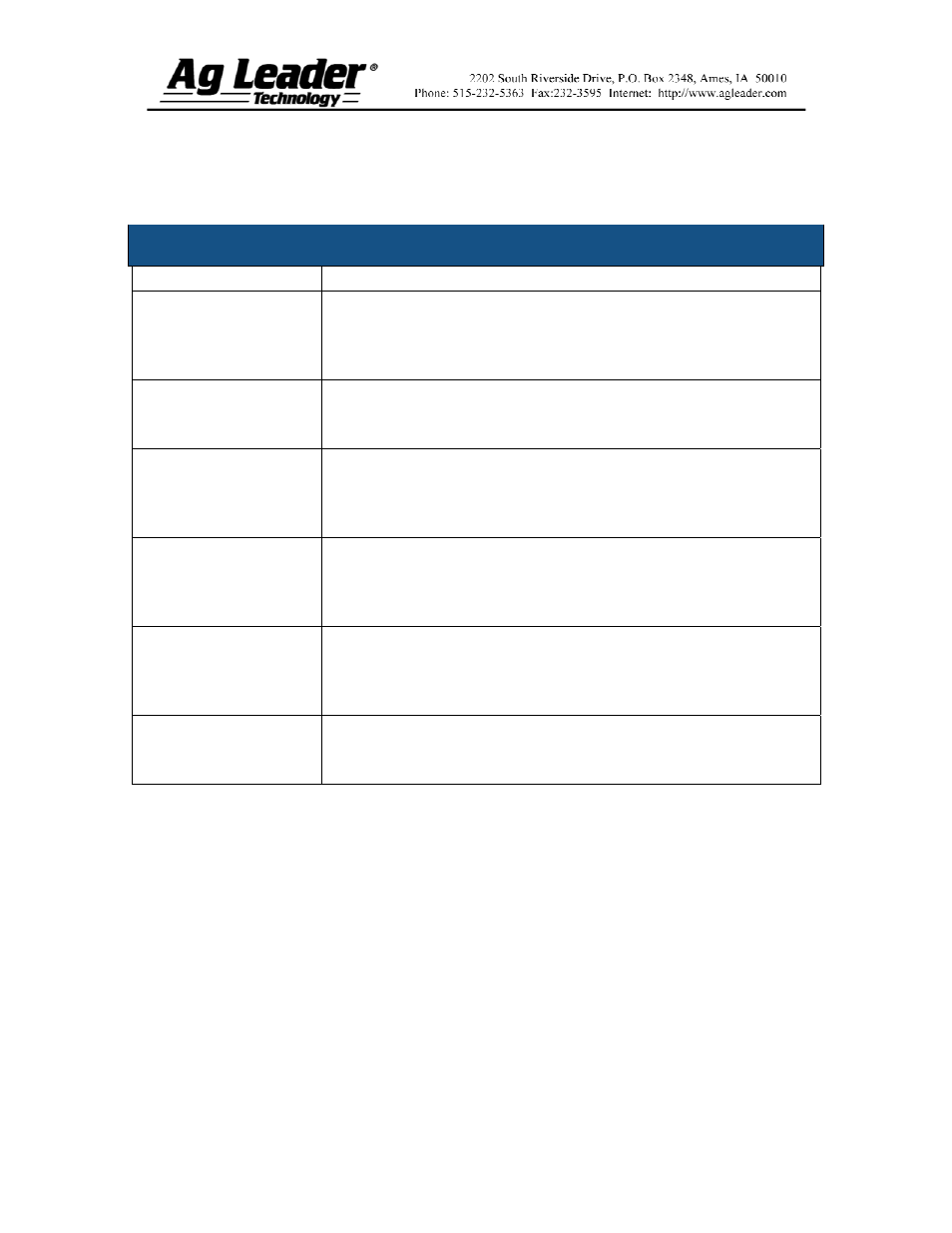

Liquid Product Control Valve Configuration Options

Control Method

Description

In-line Servo

Rate control is achieved through actuating a butterfly or ball valve

found in the solution line that goes to the booms. When the valve

opens, the flow increases and when the valve closes, the flow

decreases.

Bypass Servo

Rate control is achieved through actuating a butterfly or ball valve

found in the return line to the solution tank. When the valve opens,

the flow decreases and when the valve closes the flow increases.

PWM 12 Volt

Rate control is achieved through speed changes to the solution pump.

The PWM 12 Volt setting is programmed to pulse the power to an

electric solenoid valve used to adjust the hydraulic flow to the

solution pump.

Pump Servo

Rate control is achieved through speed changes to the solution pump.

The pump servo setting is programmed to control an electric motor

used to actuate a hydraulic valve to adjust the hydraulic flow to the

solution pump.

PWM Ground:

Rate control is achieved through speed changes to the solution pump.

The PWM ground setting is programmed to pulse the ground to an

electric solenoid vale used to adjust the hydraulic flow to the solution

pump.

Calibrated Reflow

Three-way boom valves are used to return product back to the tank in

the off state. The returned flow is calibrated with adjustment at each

valve. Calibration is required any time the nozzles are changed.