Troubleshooting – Prochem Legend SE AD User Manual

Page 49

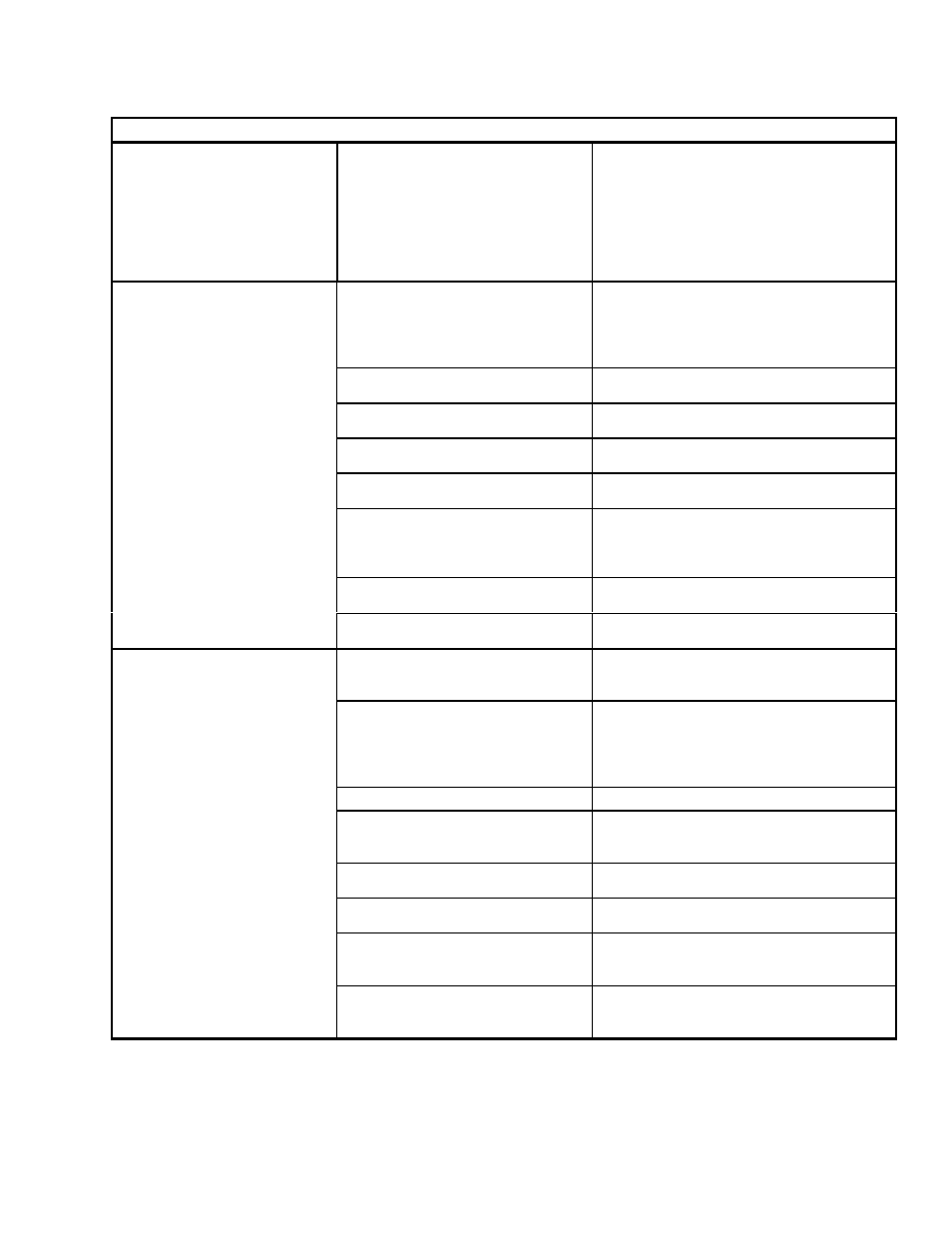

TROUBLESHOOTING

LEGEND SE 980059 07/23/02

4-17

PROBLEM CAUSE SOLUTION

Heat exchanger leaks

NOTE: The engine exhaust

heat exchanger will produce

water condensation discharge

at times during normal

operation. DO NOT confuse

this with a leak.

Engine and vacuum exhaust heat

exchanger are damaged from

frozen water

Inspect heat exchanger for leaks. On pre-

heaters visually inspect for damage.

Pressure check both styles after removing

them from the unit. (Maximum test

pressure engine exhaust H.E. 1200 PSI

vacuum pre-heaters 300 PSI).

Check instrumentation settings:

Diverter valve is in the MUFFLER

position. Temperature bypass valve

is open. Temperature control is set

at a low temperature.

Turn diverter valve to the HEAT

EXCHANGER position. Close the heat

bypass valve. Set the temperature control

to a higher setting.

Defective solenoid - remains in

open position.

Inspect solenoid for proper operation.

Clean, or replace, if needed.

Temperature relief valve on water

box is stuck open.

Clean temperature relief valve and test.

Replace, if necessary.

Engine RPM is low.

Test gauge and sensor. Replace failed

component.

Defective air pump (catalytic

converter not burning).

Replace air pump.

Engine exhaust heat exchnager is

carbon-coated on outside of coil

(defective air pump).

Soak coil at a machine shop. Boil tank or

soak in an industrial cleaner. Check air

pump, replace if needed. DO NOT soak

catalytic core.

Engine exhaust heat exchanger is

scaled on inside of coil.

De-scale coil. Install water softener if

needed.

Loss of temperature

The heat output of the unit is

LESS than normal.

Excessive bypass due to loose or

damaged orifice.

Inpect bypass orifice. Repair or replace as

needed.

Automatic waster pump is

malfunctioning or not operating

normally

Debris interfering in the normal

operation of pump, pump check

valve, or float switch.

Remove pump-out from waste tank,

thoroughtly check all components, inspeck

for proper operation.

NOTE: When replacing either

the pump or float switch, use

new electrical connectors and

heat shrink. Inspect connection

for water tight seal.

Pump-out circuit breaker on the

control panel has been tripped.

After inspecting the waste pump to

determine the cause of the tripped circuit

breaker, press the reset button. (Check for

debris in the impeller inside the pump

head).

Defective waste pump float switch.

Replace float switch.

Worn out waste pump.

Check for voltage at the pump. If there is

voltage and the pump does not run, replace

the pump.

Water has penetrated the electrical

connectors.

Reseal or replace electrical connectors.

Broken wiring leading to the waste

pump.

Check for voltage at the pump. If no

voltage, find broken connection and repair.

Weak battery. Battery charge to low

to maintain pump-out operation.

Charge or replace battery, if needed. If no

voltage, find the broken connection and

repair.

Pump wired incorrectly. Pump

impeller rotates backwards

Verify rotation using arrow marking on

bottom of pump housing. Inspect using a

voltage meter.