Maintenance – Prochem Legend SE AD User Manual

Page 41

MAINTENANCE

LEGEND SE 980059 07/23/02

4-9

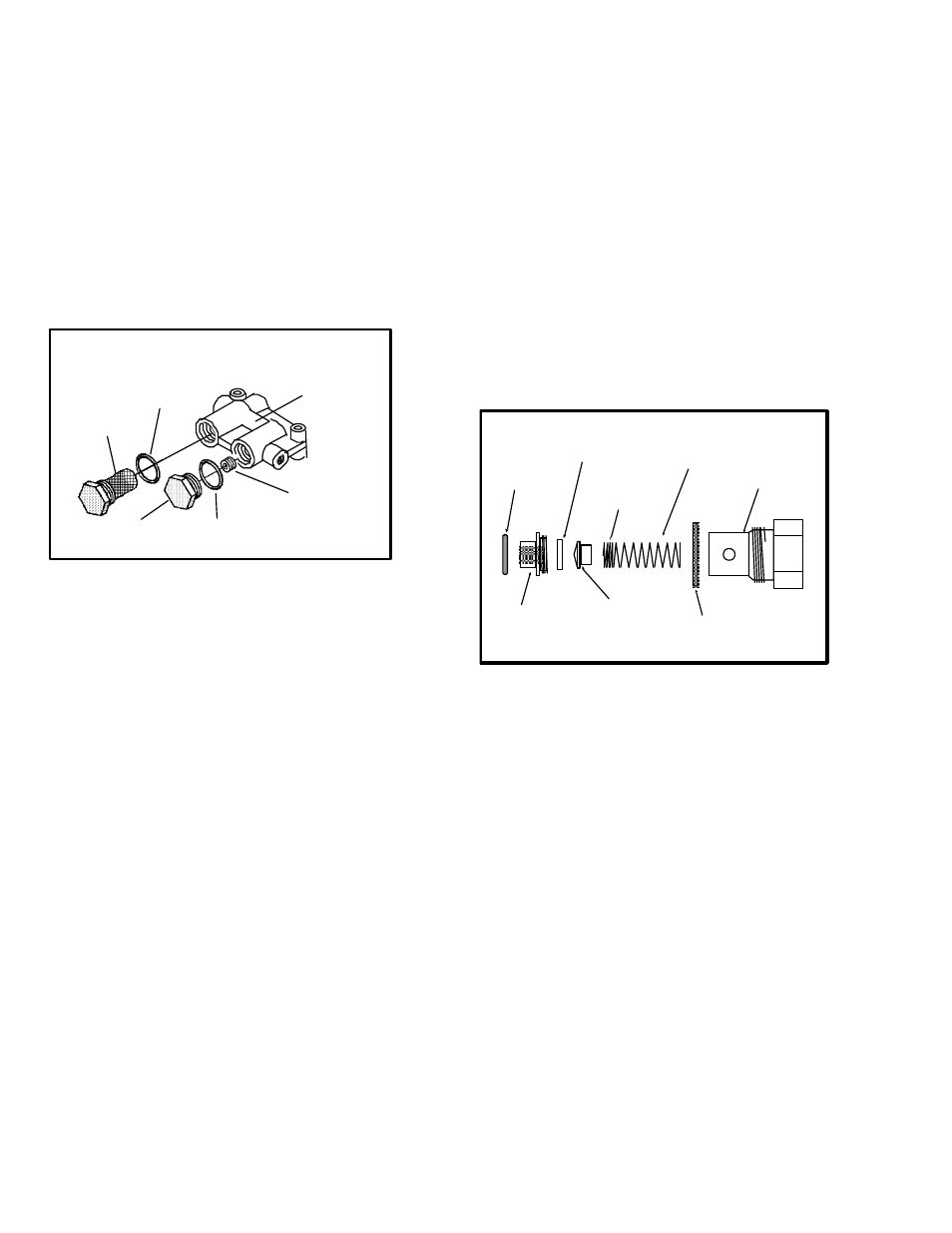

BYPASS MANIFOLD

Clean the bypass strainer and orifice using the

following guidelines:

1. Remove the strainer. Clean and re-install. DO

NOT over-tighten strainer.

2. Remove the cap. Remove the orifice, using a

3/16" Allen wrench (the 3/16" Allen wrench is

provided with Part #66-945280, the bypass

maintenance kit.)

3. Re-install the cap and run the unit with the

water pump ON for 15 seconds to flush out the

bypass manifold.

4. Remove the cap and re-install the cleaned

orifice, using the 3/16" Allen wrench. Tighten

orifice just enough to seat. DO NOT over

tighten. Re-install cap. DO NOT over-tighten

cap.

NOTE: If o-ring seals leak, replace them. If

strainer is damaged, replace strainer.

CHECK VALVE (SOLUTION OUTLET)

Inspect the check valve whenever doing service

on the chemical pump or if flow problems occur

in the chemical system:

1. Remove the check valve. Be sure the small o-

ring for the seat comes out with the check valve.

2. Remove the seat, using a 5/16" Allen wrench.

3. Check the Teflon seat for debris or wear. Clean

or replace Teflon seat if needed.

4. Clean the poppet and spring, inspect for wear or

damage, and replace as needed.

5. Re-assemble the check valve. Start the seat by

hand, tighten using a 5/16" Allen wrench. DO

NOT over-tighten seat.

NOTE: Improper seating of the check valve

poppet, damaged spring or o-rings will cause

poor operation of the chemical system.

6. Lubricate the o-rings with o-ring lubricant, Part

#05-008035, and reinstall.

(use 5/16 Allen

wrench to remove)

O-RING

SEAT

TEFLON SEAT

SPRING

O-RING

CHECK

VALVE CAP

POPPET

Tight wrap

on spring

CHECK VALVE DETAIL

STRAINER

BYPASS MANIFOLD DETAIL

O-RING

CAP

O-RING

ORIFICE

MANIFOLD