Maintenance – Prochem Legend SE AD User Manual

Page 44

MAINTENANCE

LEGEND SE 980059 07/23/02

4-12

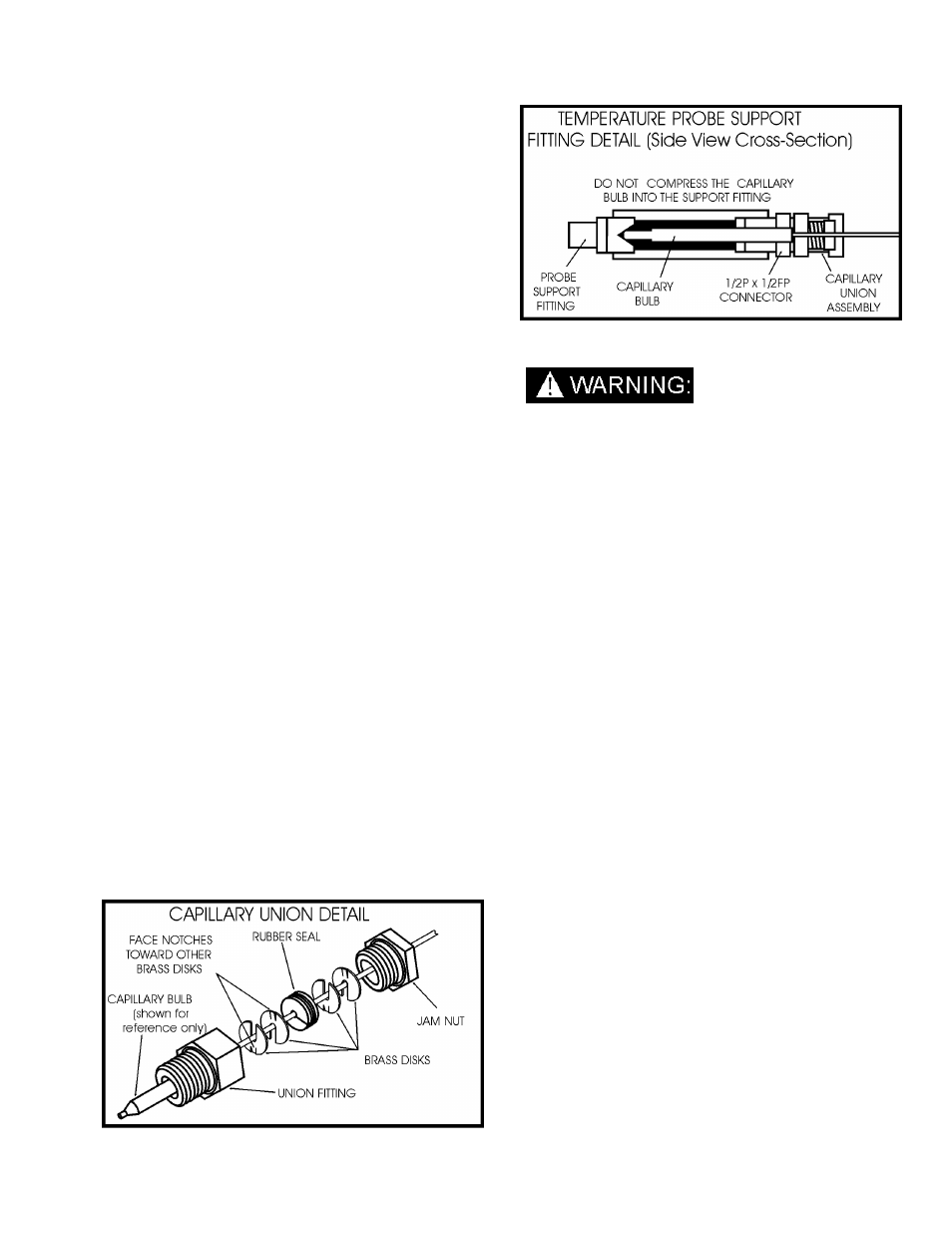

TEMPERATURE CAPILLARY & PACKING

ASSEMBLY

INSTALLATION INSTRUCTIONS

1. Using thread sealant, thread the tapered end of

the union fitting into the thermostat manifold and

tighten.

2. Slide the jam nut over the capillary bulb with the

threaded end toward the end of the capillary bulb.

3. Insert the capillary bulb through the union fitting

and into the thermostat manifold.

4. Place the rubber seal onto the capillary tube with

the split facing 90

°

from the top (see the capillary

union detail).

5. Fit the four brass disks onto the capillary tube,

with two of the brass disks on each side of the

rubber seal. Face the notch on one brass disk

toward the nearby brass disk to lock the brass

disks together. Then face the notches on the

brass disks 90

°

from the split in the rubber seal.

NOTE: Lubricating the facing sides of the brass

disks will hold them together on the capillary

tube during installation

.

6. Insert the rubber seal and brass disks into the

union fitting, hand tight.

7. Position the capillary bulb in the temperature

manifold as shown in the illustration. When

positioning the capillary bulb, do not allow the

bulb to compress against the support fitting.

8. Tighten the jam nut lightly, about 1-1/2 turns.

9. Examine the capillary union assembly for leaks

and tighten the union fitting just enough to stop

leaks. DO NOT over-tighten.

TROUBLESHOOTING

DO NOT service this unit while it is running. The

high-speed mechanical parts as well as high

temperature components may result in severe

injury, severed limbs, or fatality.

This chapter of the operator’s manual explains how to

look for and repair malfunctions which may occur.

Intelligent, accurate troubleshooting is based on a

complete and thorough understanding of the

WATER, VACUUM, CHEMICAL, HEAT TRANSFER,

SAFETY and WIRING systems on this unit.

If there is a malfunction occurring in a system which

you do not fully understand, turn back to the

"Operation" section of this manual and review

"Systems".

In addition, prior to proceeding, you can save

time by checking that:

1. The water supply is ON.

2. The engine speed at full throttle is 2600 RPM,

with the diverter valve in the HEAT EXCHANGER

position.

3. Check that water pump volume is correct. Check

the pump volume with the cleaning tool closed.

Measure the water flow returning to the water box

from the pressure regulator. The flow rate should

be 3.0 GPM. An additional .2 GPM of water

should be flowing through the bypass manifold

orifice, which is adjacent to the water box. If you

block the heat bypass flow, the flow rate will be

3.2 - 3.3 GPM.