Maintenance – Prochem Legend SE AD User Manual

Page 36

MAINTENANCE

LEGEND SE 980059 07/23/02

4-4

WATER PUMP

Refer to the Water Pump Operation and Service

Manual for specific instructions.

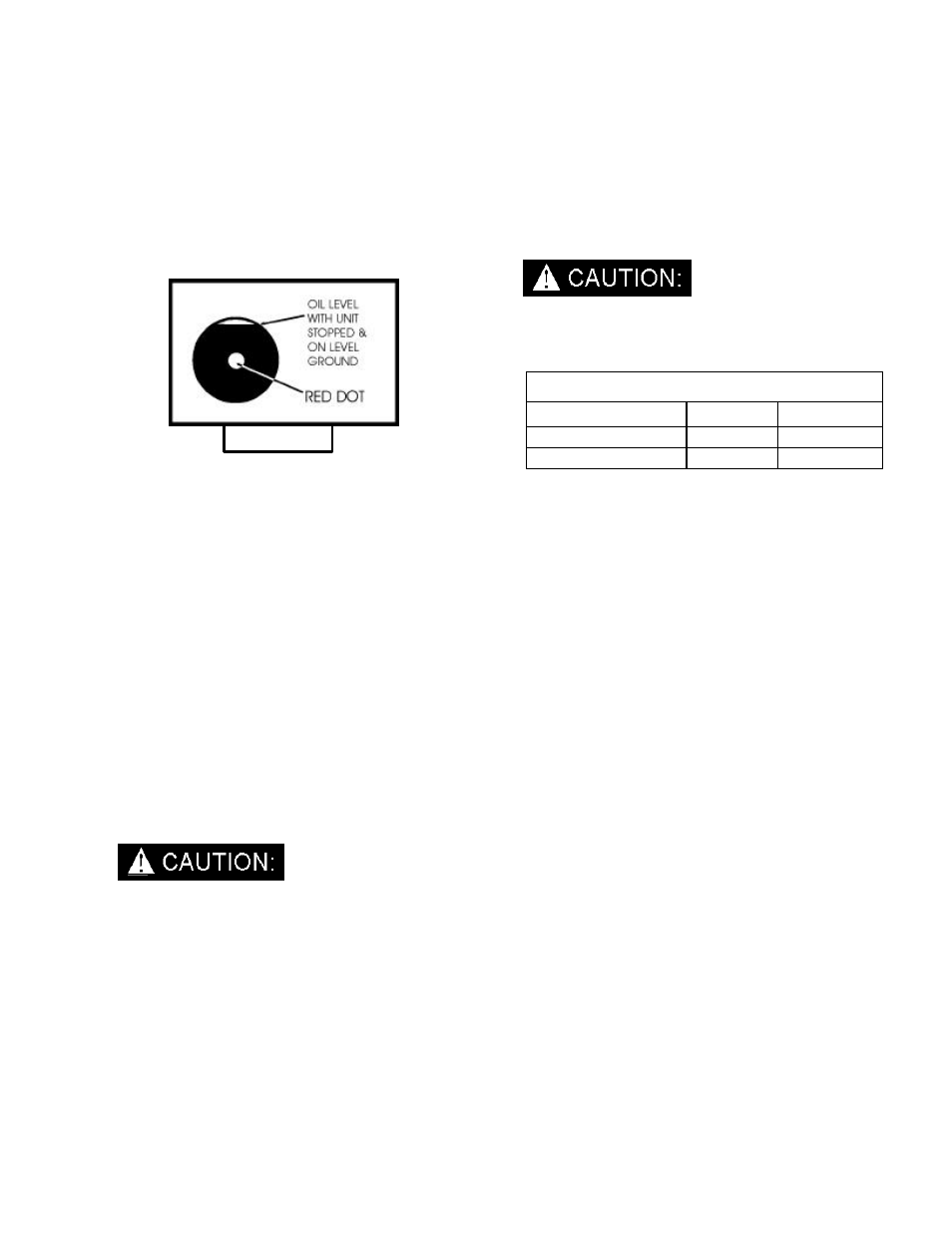

1. Check the crankcase oil level daily to assure the

proper level. Use Figure 20 as a guide when

checking the oil level. If the level has dropped,

check for the source of leakage and repair.

2. Change the crankcase oil with Cat Pump

Crankcase Oil, Part #05-008016, after the first

50 hours of operation. Drain and refill the

crankcase oil with Cat Pump Crankcase Oil

every 500 hours thereafter.

3. Other Cat approved oil equivalents are: Mobil

DTE 16, Amoco Rykow 68, and Shell Tellus T68.

VACUUM INLET FILTER (IN WASTE TANK)

1. The vacuum filter in the waste tank should be

removed and cleaned daily. If this is done, the

filter will last for a long period of time.

2. Inspect the vacuum inlet filter inside the waste

tank. If there is any lint or debris, remove and

clean filter. Re-install the filter hand-tight.

Replace this filter yearly.

When removing the vacuum inlet filter, grip the

plastic hexagonal section of filter. Grasping filter

by the screen may collapse or ruin the filter.

NOTE: When replacing this filter, we recommend

using only a stainless steel Prochem filter, Part

#14-806518.

DRIVE BELTS, PULLEYS, & HUBS

1. Check pulley set screws and/or hub cap screws

after the first 25 hours and then again at 100 hours.

Re-torque these screws with a torque wrench, using

the values on the chart on the next page. Check

pulley set screws and/or hub cap screws every 500

hours thereafter.

Make certain that when you re-torque these

screws, that you use a clockwise pattern and

continue until proper torque is achieved.

TORQUE VALUES

COMPONENT

INCH/LBS

FOOT/LBS

Engine hub

720

60

Vacuum pump hub

192

16

2. Check for pulley groove wear, clean belts and

pulley grooves, check for worn belts, proper belt

tension, and pulley alignment after the first 25

hours and then again at 100 hours.

Check for belt ride in the groove. In multiple

groove drives, belt ride should be uniform, not

more than 1/16" above or below top of pulley

groove.

Check groove wear area for wear. Side wall of

groove should be straight, not dished out. Bottom

of groove should show no signs of belt contact.

Inspect belts for contaminants, such as oil or

grease. Wipe belts clean with detergent and

water. Inspect pulley grooves for buildup of such

material and remove, if necessary.

Check wear surfaces of belt for excessive wear.

If they have a slick, glazed look, belts are

slipping. Check belt tension. Never replace one

belt in a used set, as used belts will elongate.

Replace entire set if replacement is necessary.

Place a straight-edge across the top of belt.

There should be no more than 1/2" deflection in

the center of the belt, halfway between the

pulleys. If there is too much slack, tighten belt,

making sure that it stays properly aligned.

See the "General Service Adjustments” section

in this manual for details.

Check alignment with straight-edge, string, or

machinist level. Correct alignment to as near

perfect as possible.

FIGURE 20