References – Crystal FastCalXP Calibration Software User Manual

Page 16

Calibrating Gauges

14

FastCalXP Operation Manual

Calibration Schedule

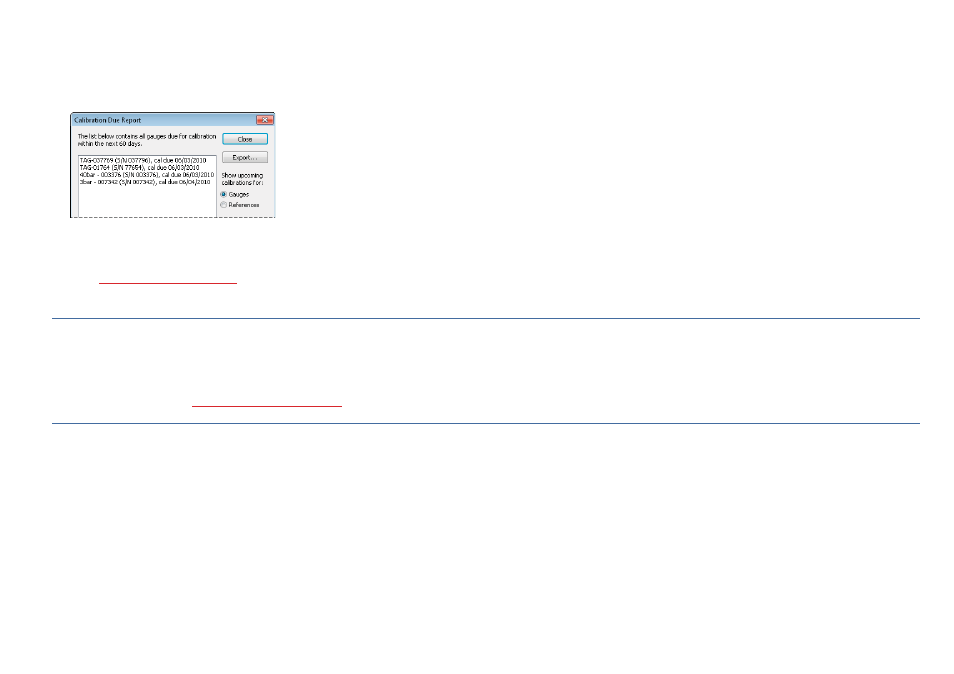

FastCalXP keeps track of the calibration schedule for all gauges and references in the database.

1

To view a list of upcoming calibrations, choose

Upcoming Calibrations Report

from the View menu.

2

Use the radio buttons to view a list of

Gauges

or a list of

References

.

The time span over which FastCalXP looks for upcoming calibrations is specifi ed under the

Confi g Settings

tab

of the FastCalXP Options. Refer to the discus-

Settings and Options on page 26

REFERENCES

A reference is the digital pressure gauge to which the gauge under test is compared during a calibration. FastCalXP is designed to work with Crystal Engineer-

ing’s nVision Reference Recorder, XP2i (XP2) digital pressure gauges, and 30 Series calibrators connected to the computers serial or USB port.

In addition to pressure references, the FastCalXP database can store references used to verify ambient conditions at the calibration work station such as ambi-

ent air pressure, temperature and humidity. These references can be automatically listed on all certifi cates. Refer to the discussion of Managing References in

the in the FastCalXP database in

Managing the Database on page 33

Reference Selection

Reference selection is perhaps the most important factor in ensuring the most accurate calibration possible. Many metrology and/or quality systems require

that the uncertainty of the reference be at least 4 times better than the device being tested, but your metrology requirements may be diff erent.

Crystal XP2i Digital Test Gauges have an accuracy of ±(0.02% of full scale) in the lower 20% of their ranges and an accuracy of ±(0.1% of reading) in the remain-

der of the range. 30 Series calibrators have an accuracy of ± (0.05% of reading plus 0.005% of full scale). nVision Reference Recorders have various accuracy

statements from range to range. Some ranges have 0.025% of reading accuracy from 30% to 100% of full scale. All Crystal products are available with a variety

of pressure ranges to suit a wide range of needs.