Operator mode displays, Tuning the controller manually, Controllers fitted with output 1 only – West Control Solutions N8100 User Manual

Page 24

2.3

OPERATOR MODE DISPLAYS

Once the complete cycle of Set Up Mode parameters has been displayed, the

user may then step through the Operator Mode displays (see Subsection 1.2),

making adjustments where required, before re-starting the Set Up Mode

parameter cycle, as shown in Table 2-1.

2.4

TUNING THE CONTROLLER MANUALLY

2.4.1

Controllers Fitted with Output 1 Only

Before starting to tune the Controller to the load, check that the Setpoint High and

Low Limits (SPhi and SPLo) are set to safe levels - see Subsections 2.2.12 and

The following simple technique may be used to determine values for proportional

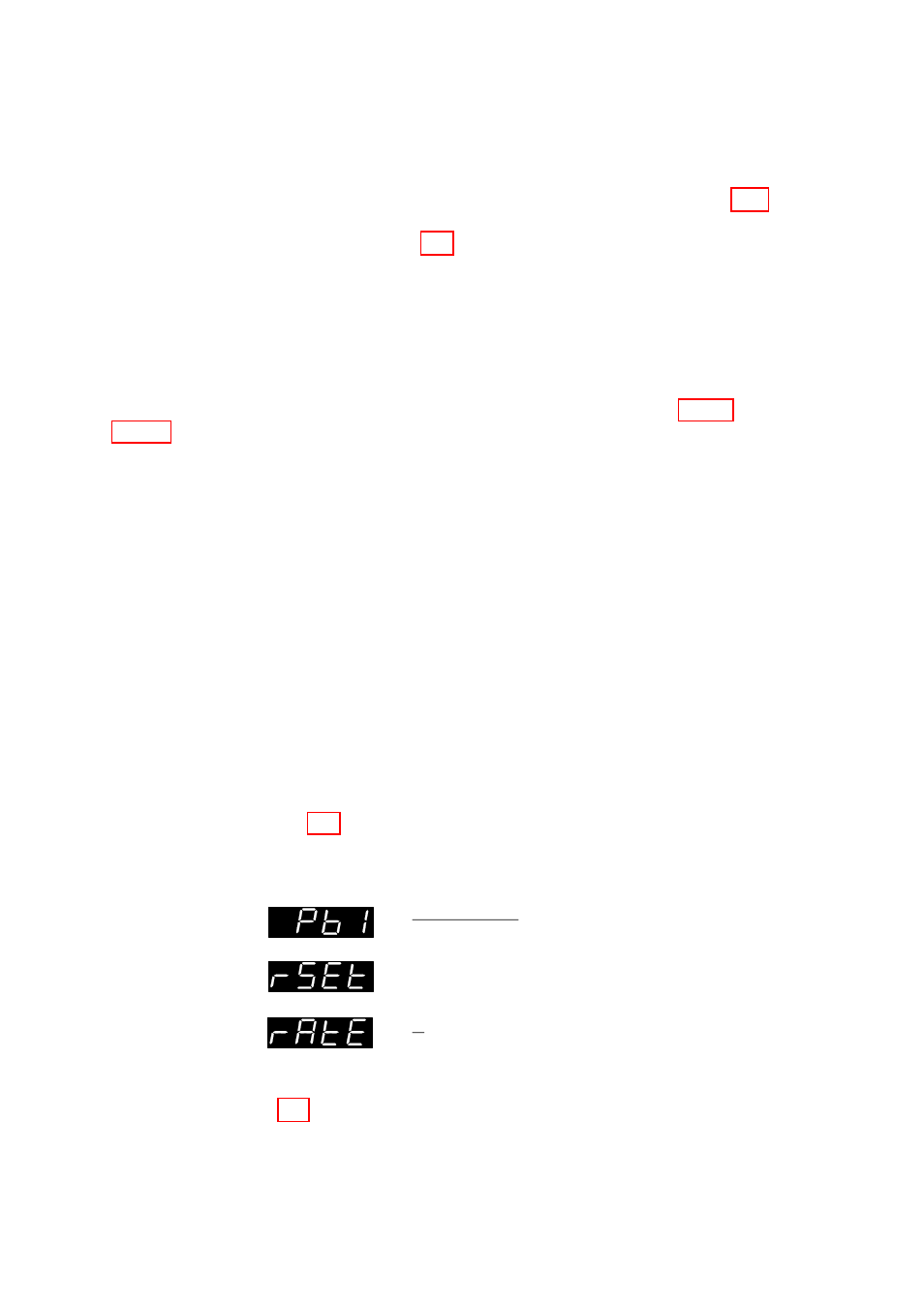

band (Pb1), derivative time constant (rAtE) and integral time constant (rSEt).

NOTE: This technique is suitable only for processes which are not harmed by

large fluctuations in the process variable. It provides an acceptable basis

from which to start fine tuning for a wide range of processes.

1. Set the setpoint to the normal operating process value (or to a lower

value if overshoot beyond this value is likely to cause damage).

2. Select ON/OFF Control (i.e. set Pb1 = 0).

3. Switch on the process. The process variable will oscillate about the

setpoint. Note (a) The peak-to-peak variation (P) of the first cycle i.e. the

difference between the highest value of the first overshoot and the lowest

value of the first undershoot, and (b)tThe cycle time (T) of this oscillation in

minutes (see Figure 2-4)

4. The control parameters should then be set as follows:

=

P

ScaleRange

x 100

= T minutes

=

T

6

minutes

NOTE: After setting up the parameters, set the Controller to Operator Mode

(see Subsection 2.6) to prevent unauthorised adjustment to the values.

2-13

O054-2

59125