Installation – Lincoln Electric IM866 POWER REAM User Manual

Page 8

INSTALLATION

- 8 -

POWER REAM

Air Connection

Use only regulated, filtered, non lubricated air. Mount a 5 micron airline filter

(not supplied) in the airline of the reamer.

AIR SUPPLY REQUIREMENTS: 80 PSI at 15 SCFM. Connect the inlet

supply line to the quick connect pneumatic fitting located on the side of the

unit.

Electrical Connections

WARNING: Damage to equipment may occur if connected improperly.

Only a qualified technician should perform the following operation.

-Secure the 6-pin connector into the receptacle on the base of the POWER

REAM and feed the other end through a strain relief into the robot

controller cabinet or other connection points on the robotic cell.

-Connect robot I/O signals according to the following description.

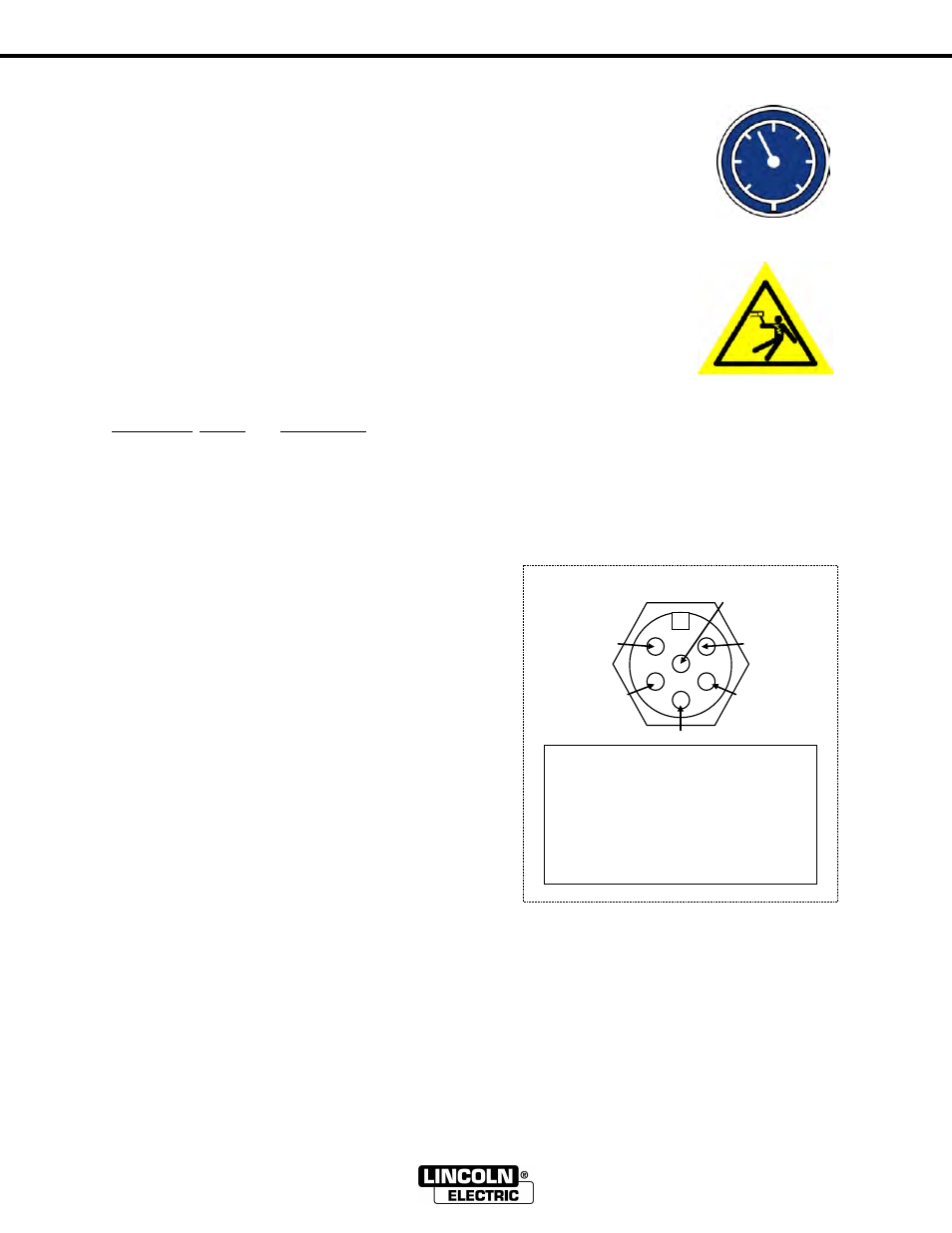

Electrical Diagram

Wire Color Name Description

Red

+24Vdc Power supply (+24Vdc, 0.5 amp)

White

0Vdc

Power supply return.

It is recommended that power to the reamer be wired concurrent with robot servo power,

interrupt-able by an E-stop condition.

Orange

Start

Robot output. Pulse this

output from the robot for

0.5sec to start the ream cycle.

Black

Spray

Robot output. Pulse this

output from the robot for

approx. 0.5 sec while

positioned over the sprayer.

To activate the

Wire Cutter,

turn on both the start and

spray outputs at the same

time or subsequently.

Green

Complete Robot input. The robot should

check this input before and

after a reaming cycle.

Blue

Error

Robot input. The robot can

check this input after a

reaming cycle to ensure error

free operation. Refer to

Diagnostics section for error

codes.

The POWER REAM detects sinking or sourcing outputs from the robot and is capable of sinking

or sourcing signals to the robot. Before connecting ensure I/O configuration is compatible with

robot. POWER REAM factory setup is for robots with sinking outputs and active high inputs.

1

2

3

4

5

6

Wiring

1. 0V DC

(WHT)

2. +24V DC

(RED)

3. Complete (GRN)

4. Start

(ORG)

5. Spray

(BLK)

6. Error

(BLU)

Interface Receptacle