Maintenance and troubleshooting - 19 – Lincoln Electric IM866 POWER REAM User Manual

Page 19

MAINTENANCE AND TROUBLESHOOTING

- 19 -

POWER REAM

MAINTENANCE

The POWER REAM will require periodic maintenance to ensure a dependable service life. The following

schedule is recommended.

Shut off the air supply and disconnect robot control cable when making adjustments.

DAILY

• Clean surface under reaming bit.

• Check airlines for leaks and robot control cable for splits or cracks.

• Clean clamp gripping surfaces to ensure optimal nozzle gripping.

WEEKLY

• Check the fluid level in spray reservoir.

• Check the reaming bit visually.

• Check the wire cutter visually.

The service life of the cutting edges are dependant on the type of application. Inspect for dullness and

possible breakage.

YEARLY

• Inspect drive belt for wear and tension. Replace if excessive wear is evident.

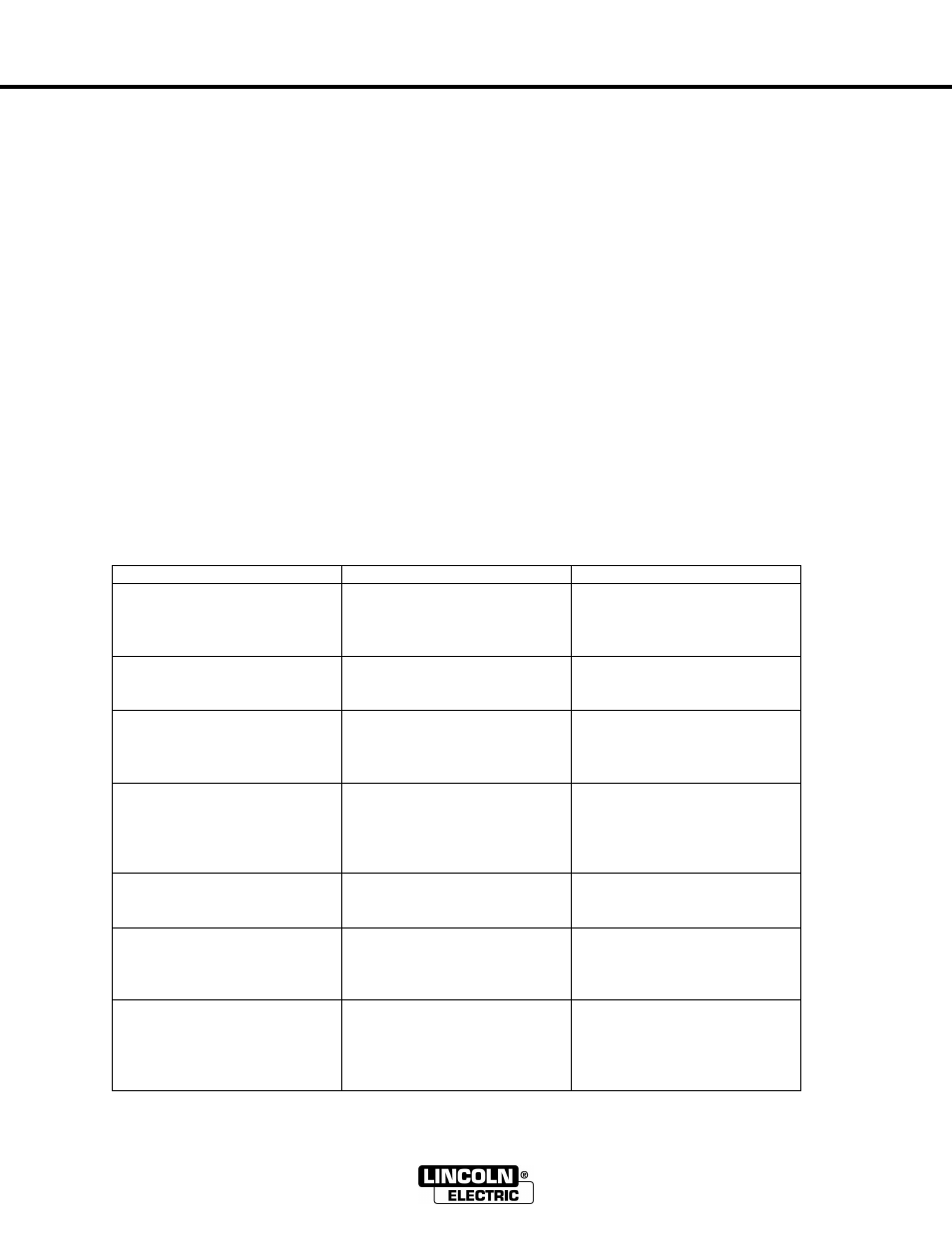

TROUBLESHOOTING

Problem

Possible Cause

Solution

No Indicator lights

-Power is off

-Fuse is blown (robot cabinet)

-Reset button defective

-Circuit board defective

-Turn power on

-Replace fuse

-Replace reset button

-Replace circuit board

Reamer stops rotating

-Insufficient air supply

-Excessive spatter buildup

-Dry run mode selected

-Set to 80psi

-Ream more often

-Select automatic mode

Clamp/Motor/Lift not working

-Insufficient air supply

-Air line cut or twisted

-Reset button defective

-Check error codes

-Set to 80psi min

-Replace airline

-Replace reset button

Reamer does not go down

-Ream bit jammed in nozzle

-Lift cylinder defective

-Top sensor defective

-―Start‖ output held on

-Check error codes

-Replace damaged parts

-Replace lift cylinder

-Replace top sensor

-Pulse ―Start‖ output 0.5 sec

Robot cannot start a cycle

or

Robot cannot complete a cycle

- ―Complete‖ signal not

responding

-Check error codes

No Anti-Spatter liquid

Or air flow from sprayer

-Insufficient air supply

-Solenoid valve defective

-Spray nozzle clogged

-Set to 80psi

-Replace solenoid valve

-Clean or replace spray nozzle

*hand tighten only

Air flow from sprayer but

no Anti-Spatter liquid

-Check anti-spatter level

-Check vent on reservoir

-Fluid line blocked

-Spray nozzle clogged

-Refill reservoir

-Open vent if closed

-Clean or repair fluid line

-Clean or replace spray nozzle

*hand tighten only