Operation - 15 – Lincoln Electric IM866 POWER REAM User Manual

Page 15

OPERATION

- 15 -

POWER REAM

Operation

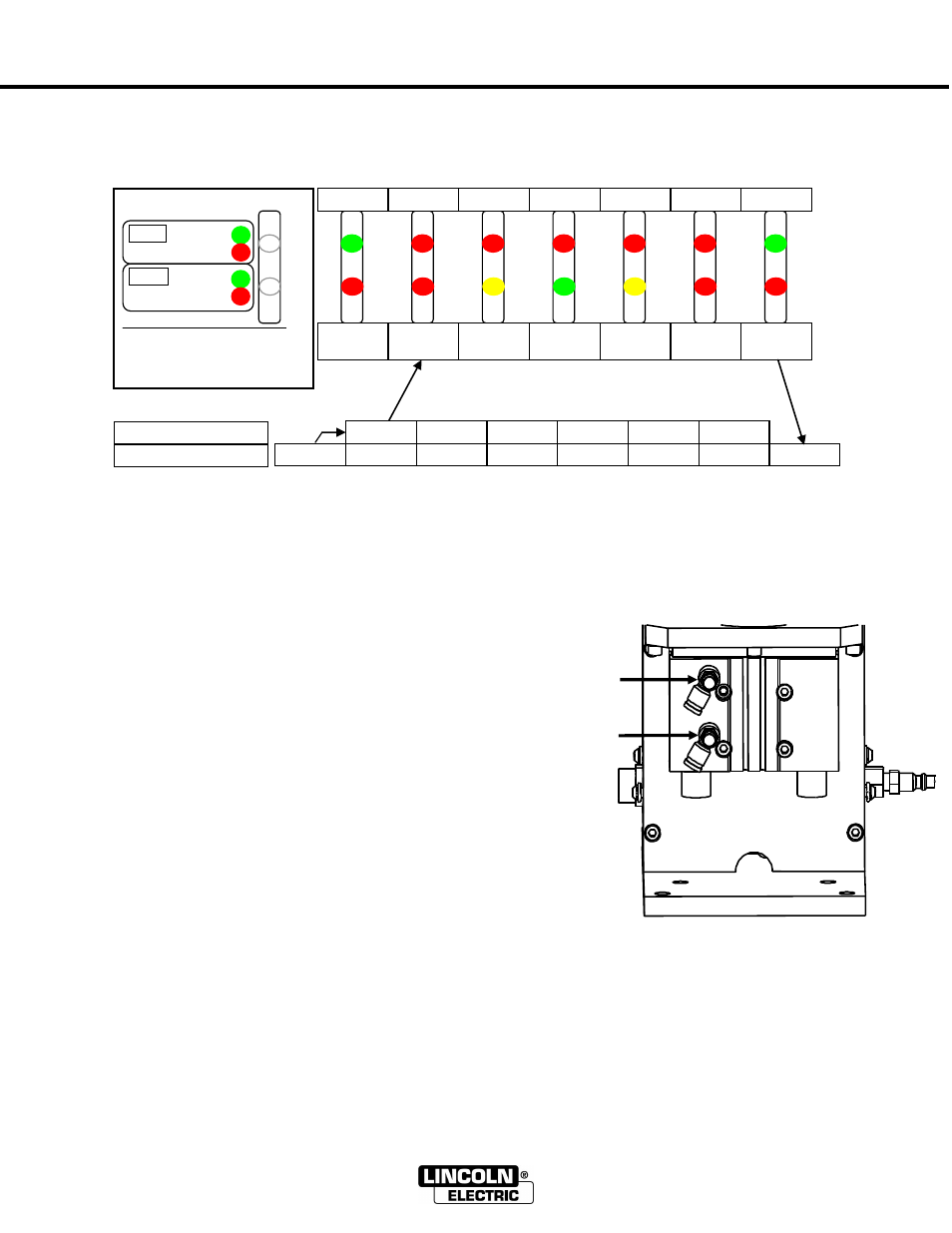

The following diagram shows the 7-step reaming sequence and color of the indicator lights at each stage.

The indicator lights show the position of the clamp and lift cylinders on the user interface.

The above diagram shows the robot input and output as the sequence progresses.

Automatic Retry

If excessive spatter is built up in the nozzle, or programmed position of the nozzle is off center

not allowing reamer to extend to full depth within a specific amount of time, the POWER REAM

will automatically retry once.

Cycle Optimization

The lift rate of the reaming bit will determine how many reaming

revolutions will occur within the nozzle. This parameter should be

set based on the amount of spatter built up in the nozzle between

reaming cycles. More spatter buildup will require a slower lift rate.

Less spatter buildup will allow a faster lift rate.

To set the lift rate, remove the front cover and adjust the top

needle valve. Turning clockwise will decrease the lift rate (for more

spatter removal), and turning counter clockwise will increase the lift

rate.

To set the retracting rate, adjust the bottom needle. Turning

clockwise will decrease the retracting rate, and turning counter

clockwise will increase the retracting rate.

G

R

G

R

Clamp

Open

Closed

Lift

Top

Bottom

R

R

R

Y

R

G

R

Y

R

R

G

R

G

R

Ready

Clamp

Closed

Raising

Reamer

Reamer at

Top

Lowering

Reamer

Reamer at

Bottom

Clamp

Open

1

2

3

4

5

6

7

Pulse 0.5s

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

Off

On

On

―

Start‖ Output from robot

―

Complete‖ Input to robot